Flat-bulb steel storage equipment, storage and transportation device and transportation method

A technology of flat bulb steel and equipment, which is applied to ships and other directions, can solve the problems of flat bulb steel deformation, many auxiliary tools, and affect the accuracy of bulb flat steel, and achieve the effect of avoiding deformation, avoiding stacking and extrusion, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

[0050] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

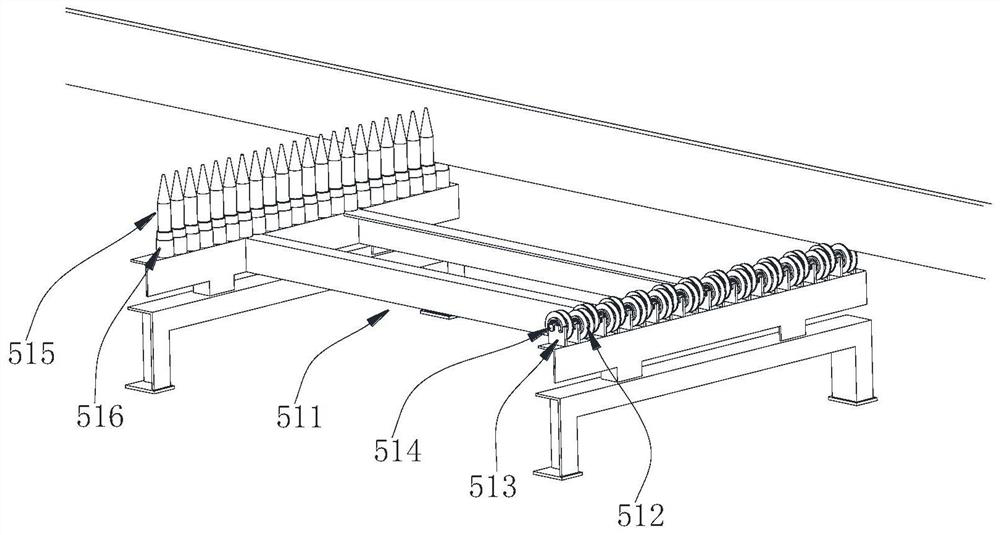

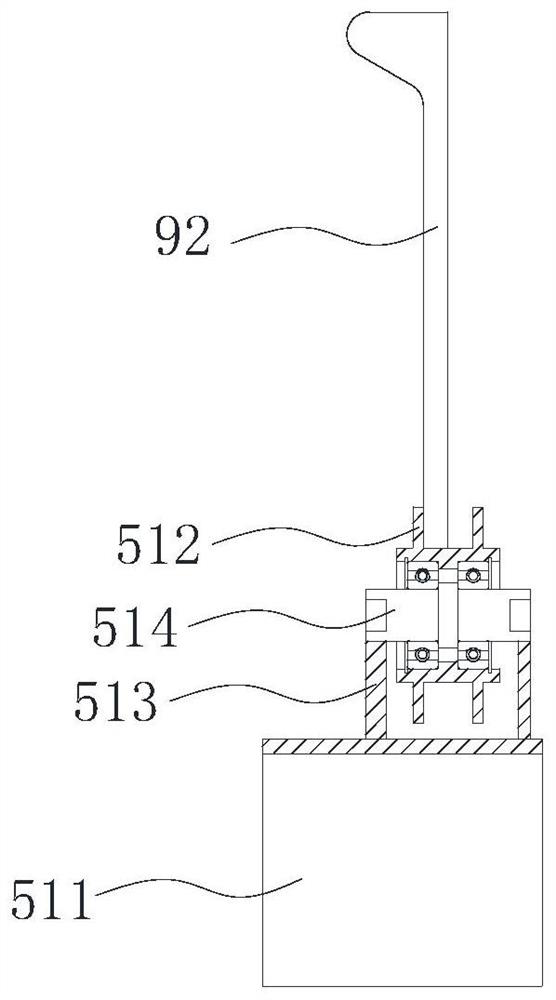

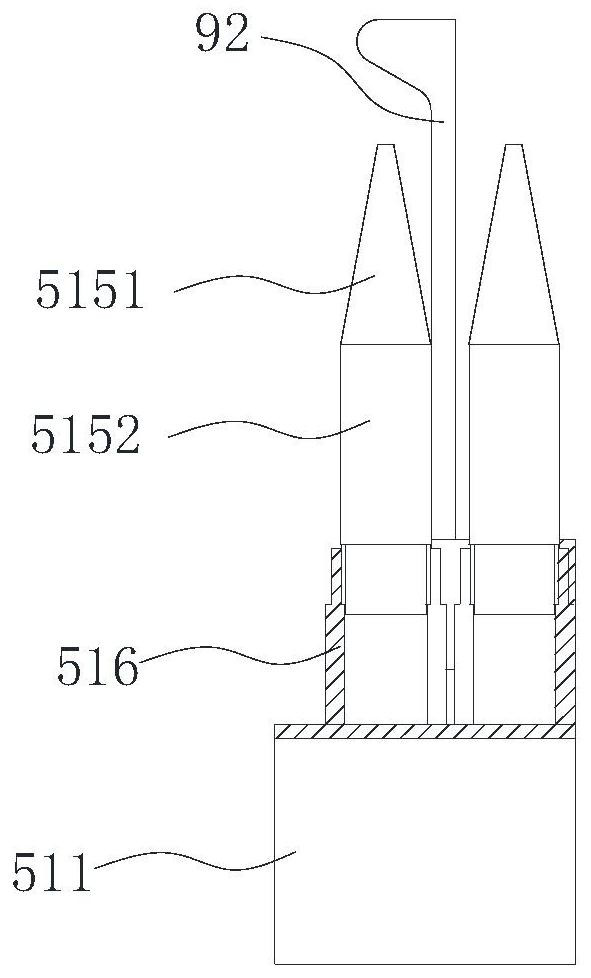

[0051] The invention provides a storage and transportation device for the flat bulb steel 91, which is used for storage and transportation of the flat bulb steel 91. Wherein, the storage of the bulb flat steel 91 is realized by the storage device 5, and the transportation of the bulb flat steel 91 is realized by the positioning trolley 7 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com