Fully-automatic friction bag taking type spindle packaging and transporting device

A fully automatic packaging and transportation device technology, applied in packaging, packaging machines, transportation packaging, etc., can solve problems such as difficulties in automatic packaging, achieve the effects of improving production efficiency and economic benefits, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

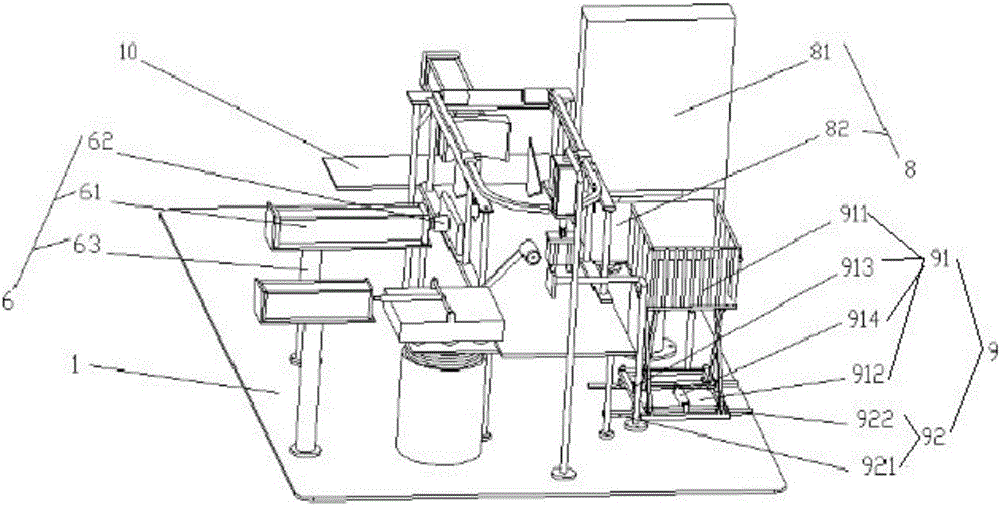

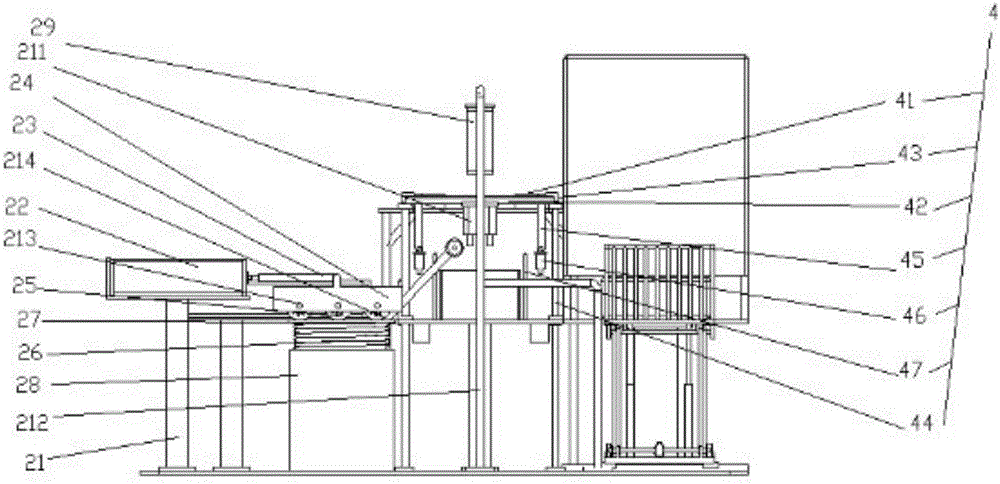

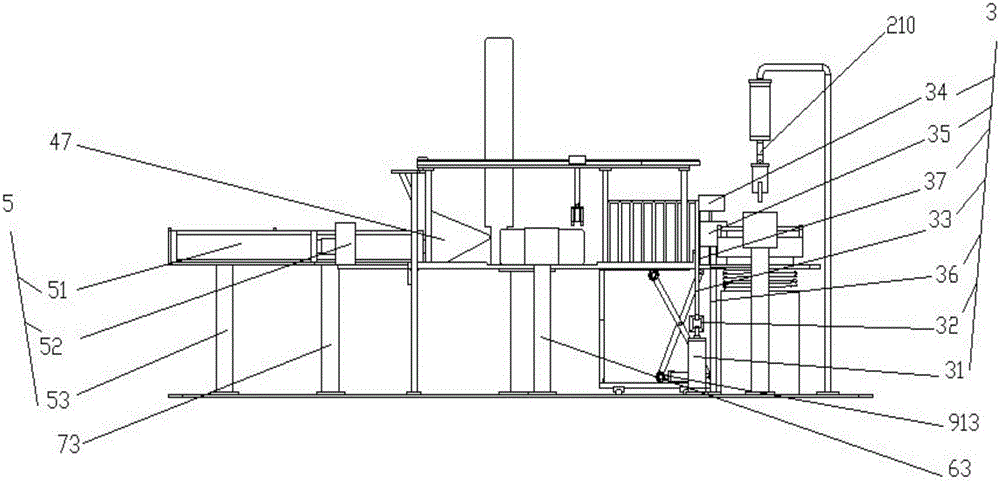

[0022] Such as figure 1 , 2 , shown in 3, 4, a kind of frictional bag-taking type spindle full-automatic packaging transport device comprises: frame 1, bag taking device 2, opening device 3, bag supporting device 4, bagging device 5, push device 16, push Device II7, sealing device 8, transport device 9, assembly line 10; bag taking device 2 includes: cylinder mounting table I21, cylinder I22, cylinder joint I23, moving box 24, friction wheel I25, spring 26, dividing plate 27, spring placement box 28. Cylinder II29, cylinder connector II210, finger cylinder I211, bracket I212; the cylinder mounting table I21 is fixed on the lower bottom plate of the frame 1 through bolts, the cylinder I22 is mounted on the cylinder mounting table I21, and one end of the cylinder joint I23 is inserted into the cylinder The piston rod of I21, the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com