Plug tray placing machine

A plug tray and scissor fork technology, which is applied in the field of plug tray placement machines, can solve the problems of difficulty in reducing the cost of seedlings, high labor intensity, and affecting the quality of seedlings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

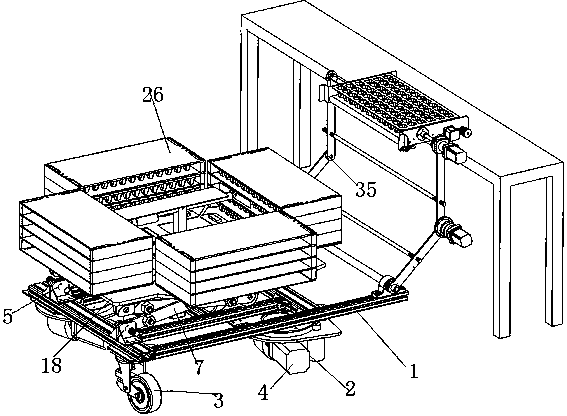

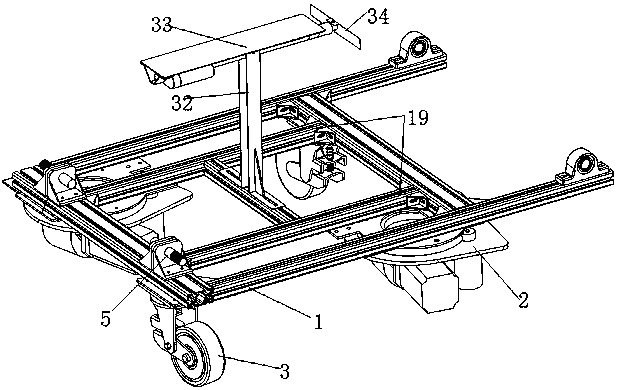

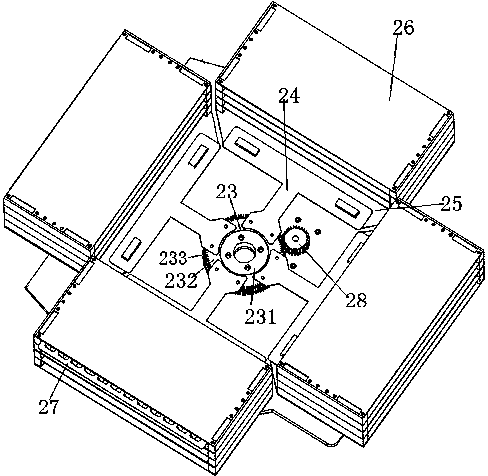

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] Such as Figure 1 to Figure 7 As shown, the tray placement machine has a base 1, the base 1 can be surrounded by profiles, two AGV steering wheels 2 and two universal wheels 3 are installed on the bottom of the base 1 along the diagonal, and the AGV steering wheel 2 is installed There is a driving motor 4, which can drive the AGV steering wheel 2 to move. The combination of the AGV steering wheel 2 and the universal wheel 3 can realize turning without radius, so that the whole device can move freely and smoothly, and realize transportation.

[0023] Two hinge seats 5 are installed on the base 1, on which the first scissor bar 6 and the second scissor bar 7 are hinged respectively, and two hinge seats 8 are installed on the support plate 18 above the base 1, on which respectively hinge The third scissor bar 9 and the fourth scissor bar 10, and the first scissor bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com