End underframe lifting device for automobile-container dual-purpose concave-bottom transport vehicle

A lifting device and container technology, which is used in the transportation of passenger cars, transportation and packaging, railway car body parts, etc. Economically significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

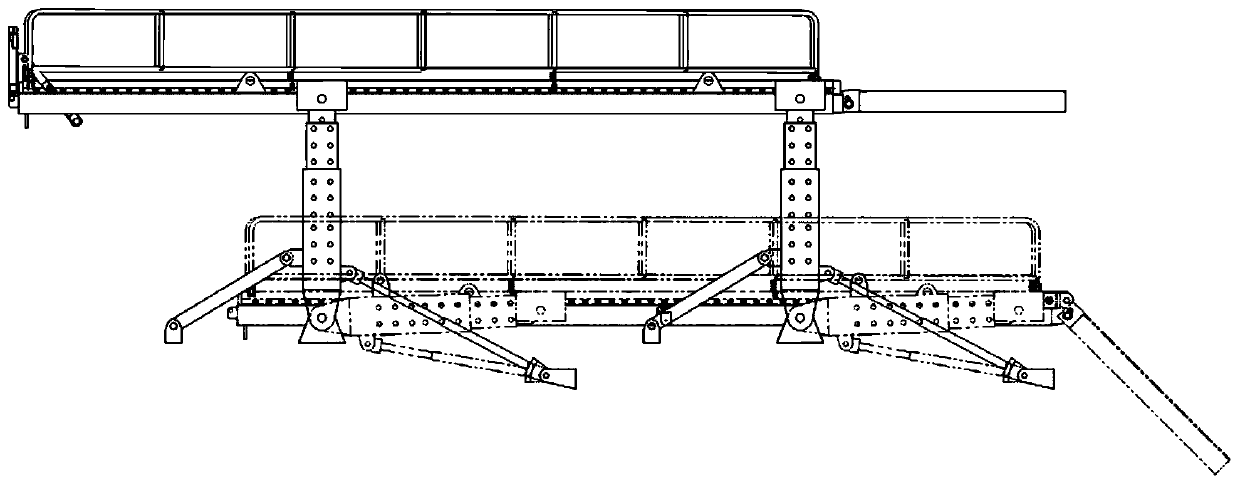

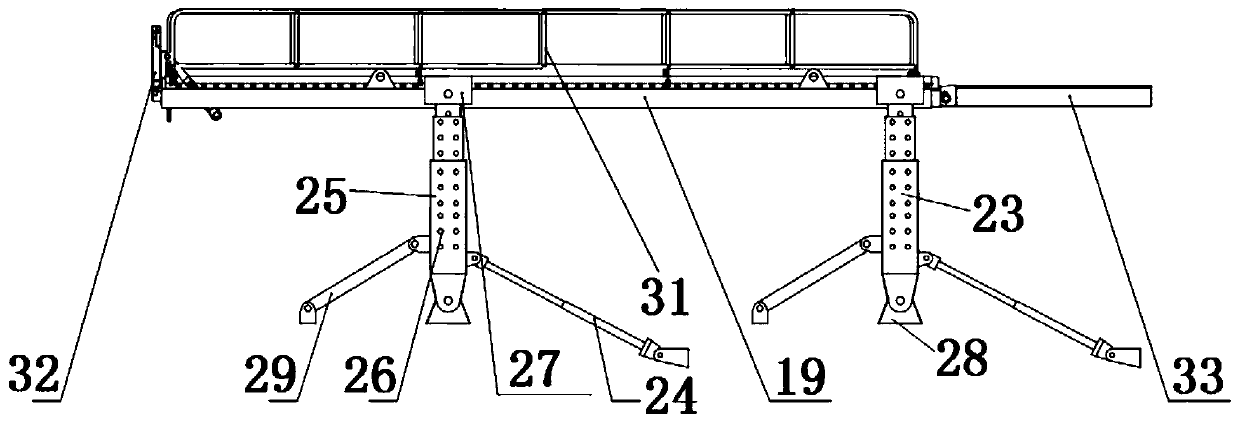

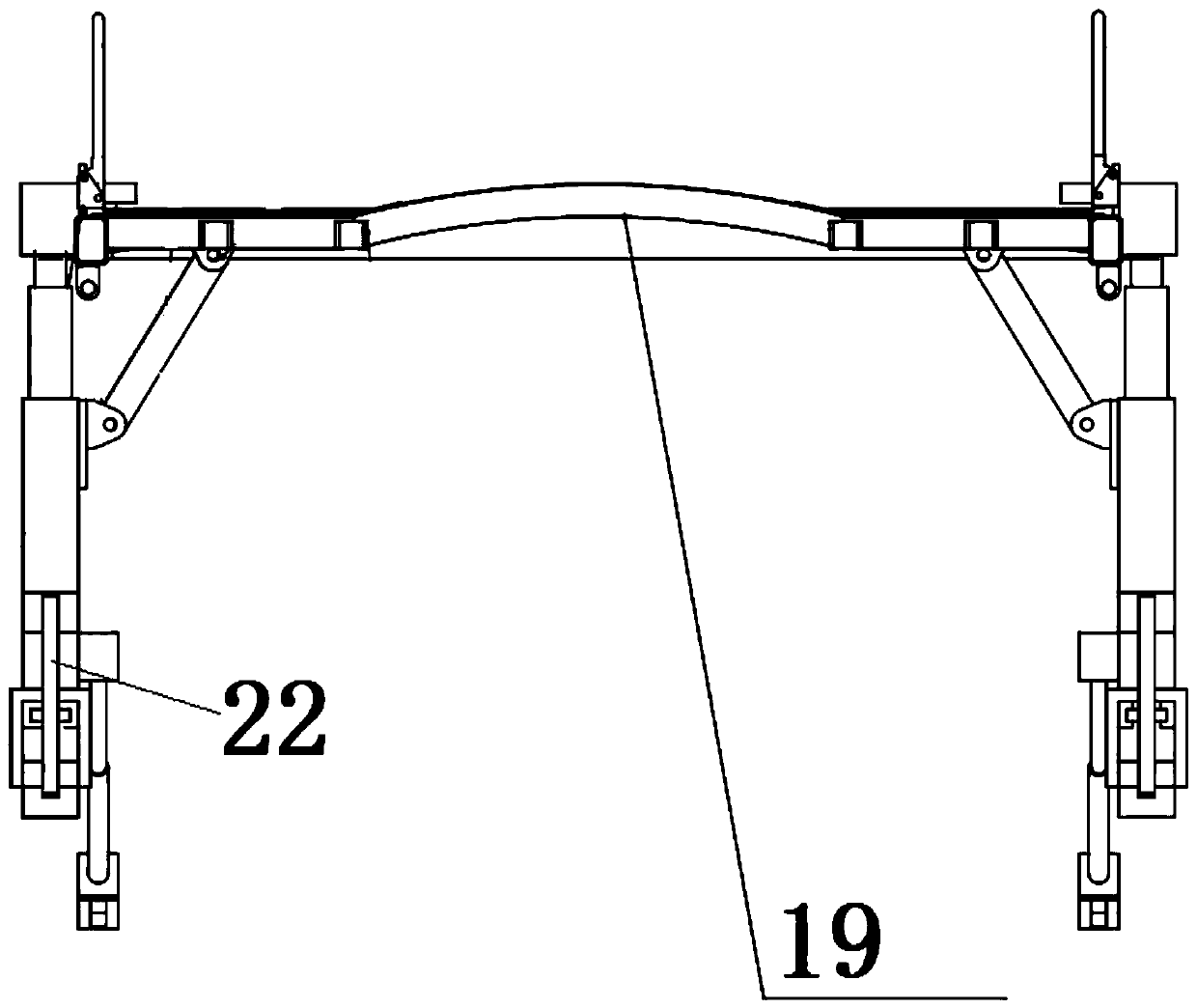

[0034] See attached Figure 1-11 . An end chassis lifting device for an automobile-container dual-purpose concave bottom transport vehicle, comprising a lower chassis 1, an upper chassis 19 at the end and a control device for the upper chassis; the lower chassis 1 is provided with a concave bottom 5 in the middle, Both ends are provided with a high bottom 20, and the concave bottom 5 and the high bottom 20 are connected by an inclined bottom 21; the upper bottom frame 19 at the end corresponds to a high bottom 20, and there is a Four end-on-shelf control devices, wherein a pair of end-on-shelf control devices are symmetrically arranged at the front and rear positions of the upper bottom frame 19 at the end; said end-on-shelf control devices include an end-on-shelf lifting device 22, a multi-stage telescopic sleeve 23 and an end-on-shelf rotating device 24; the multi-stage telescopic sleeve 23 includes several support sleeves 25 nested sequentially from the inside to the outsi...

Embodiment 2

[0036] See attached Figure 1-11. An end chassis lifting device for an automobile-container dual-purpose concave bottom transport vehicle, comprising a lower chassis 1, an upper chassis 19 at the end and a control device for the upper chassis; the lower chassis 1 is provided with a concave bottom 5 in the middle, Both ends are provided with a high bottom 20, and the concave bottom 5 and the high bottom 20 are connected by an inclined bottom 21; the upper bottom frame 19 at the end corresponds to a high bottom 20, and there is a Four end-on-shelf control devices, wherein a pair of end-on-shelf control devices are symmetrically arranged at the front and rear positions of the upper bottom frame 19 at the end; said end-on-shelf control devices include an end-on-shelf lifting device 22, a multi-stage telescopic sleeve 23 and an end-on-shelf rotating device 24; the multi-stage telescopic sleeve 23 includes several support sleeves 25 nested sequentially from the inside to the outsid...

Embodiment 3

[0041] See attached Figure 1-11. An end chassis lifting device for an automobile-container dual-purpose concave bottom transport vehicle, comprising a lower chassis 1, an upper chassis 19 at the end and a control device for the upper chassis; the lower chassis 1 is provided with a concave bottom 5 in the middle, Both ends are provided with a high bottom 20, and the concave bottom 5 and the high bottom 20 are connected by an inclined bottom 21; the upper bottom frame 19 at the end corresponds to a high bottom 20, and there is a Four end-on-shelf control devices, wherein a pair of end-on-shelf control devices are symmetrically arranged at the front and rear positions of the upper bottom frame 19 at the end; said end-on-shelf control devices include an end-on-shelf lifting device 22, a multi-stage telescopic sleeve 23 and an end-on-shelf rotating device 24; the multi-stage telescopic sleeve 23 includes several support sleeves 25 nested sequentially from the inside to the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com