Crushing anti-blocking device for chemical industry

A pulverizing device and anti-clogging technology, applied in chemical instruments and methods, solid separation, sieves, etc., can solve the problems such as the inability to achieve alternate vibration of movable discs to prevent clogging and material clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

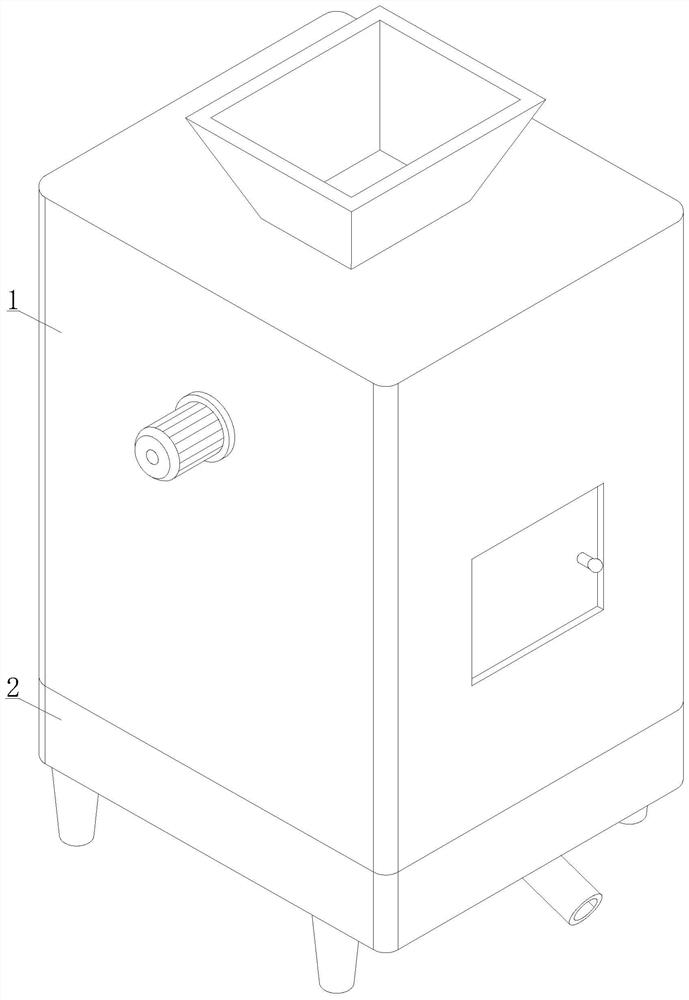

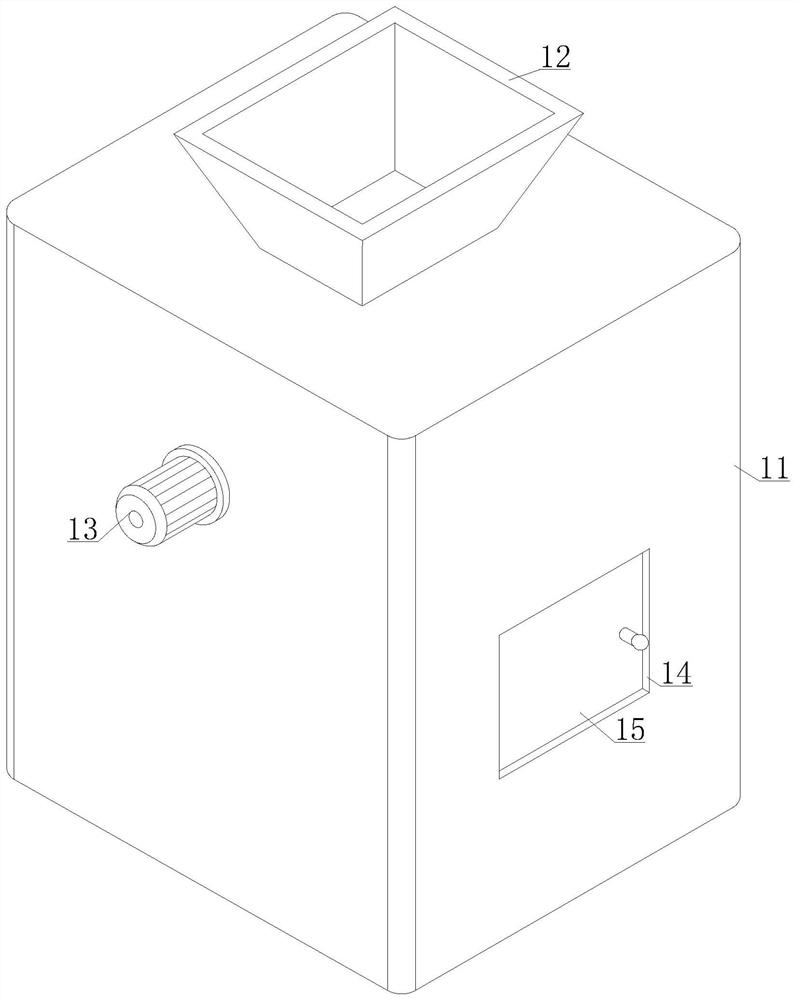

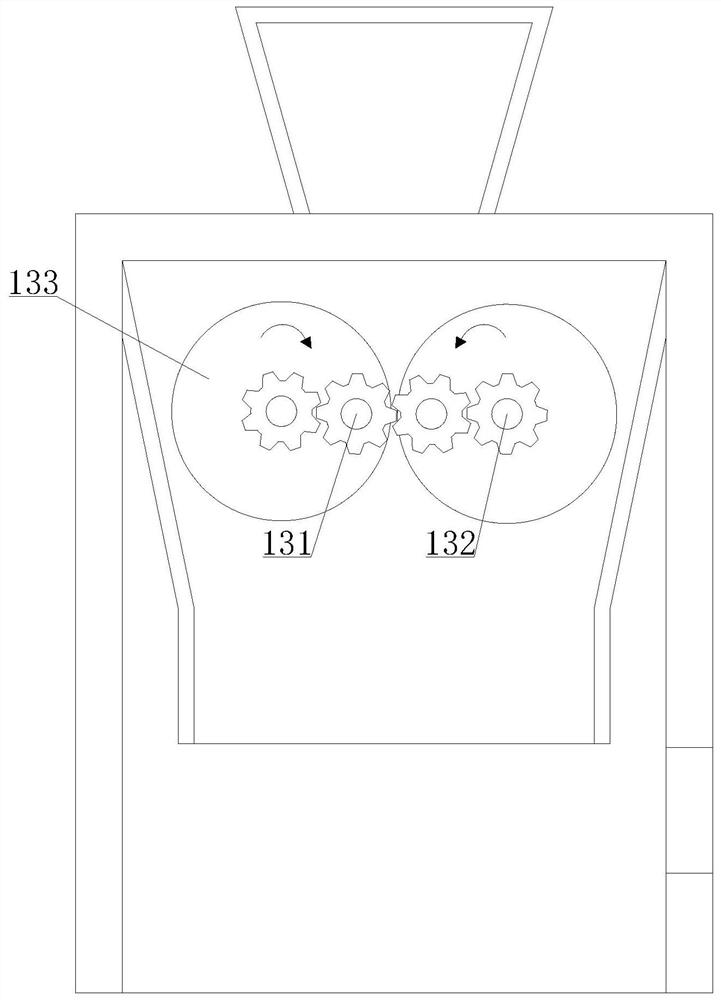

[0028] see Figure 1-3 , a crushing anti-clogging device for chemical industry, comprising a crushing device 1 and a base assembly 2, the lower end of the crushing device 1 is equipped with a base assembly 2, and the crushing device 1 includes a main box 11, a first feed port 12, a first drive motor 13 , the first driving motor 13 comprises a driving wheel 131, a driven wheel 132 and a roller shaft 133, and one side output end of the first driving motor 13 is connected with the driving wheel 131, and the two sides of the driving wheel 131 are meshed with three sets of driven wheels 132, from The other end of moving wheel 132 is equipped with roller shaft 133, and roller shaft 133 is two-way rotation, observation port 14 and push-pull plate 15, the first feed inlet 12 is installed on the upper end of main case 11, and the first feed port 12 is installed on one side of main case 11. A driving motor 13, the front of the main box 11 is provided with an observation port 14, the inn...

Embodiment 2

[0032] see Figure 1-3 , a crushing anti-clogging device for chemical industry, comprising a crushing device 1 and a base assembly 2, the lower end of the crushing device 1 is equipped with a base assembly 2, and the crushing device 1 includes a main box 11, a first feed port 12, a first drive motor 13 , the first driving motor 13 comprises a driving wheel 131, a driven wheel 132 and a roller shaft 133, and one side output end of the first driving motor 13 is connected with the driving wheel 131, and the two sides of the driving wheel 131 are meshed with three sets of driven wheels 132, from The other end of moving wheel 132 is equipped with roller shaft 133, and roller shaft 133 is two-way rotation, observation port 14 and push-pull plate 15, the first feed inlet 12 is installed on the upper end of main case 11, and the first feed port 12 is installed on one side of main case 11. A driving motor 13, the front of the main box 11 is provided with an observation port 14, the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com