Extraction device for biotechnology

An extraction device and technology, applied in the field of biological extraction equipment, can solve the problems of insufficient separation of solid particles, reduce performance, affect work efficiency, etc., and achieve the effect of being beneficial to subsequent use, improving performance, and promoting extraction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

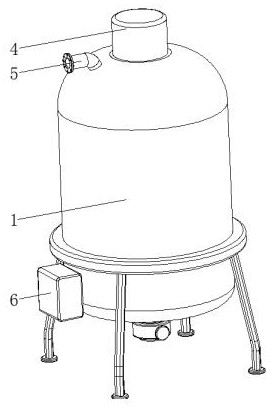

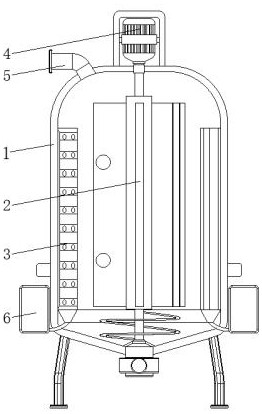

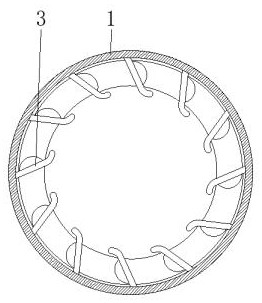

[0034] see Figure 1-8 , the present invention provides a technical solution: an extraction device for biotechnology, comprising a body 1, a stirring mechanism 2, and an impurity removal device 3, wherein the stirring mechanism 2 is arranged between the top and bottom of the inner wall of the body 1 between the corresponding two sides and At the central position, the impurity removing device 3 is arranged on the inner wall of the body 1;

[0035] A power mechanism 4 is provided at the top central position of the body 1, and the top of the rotating roller 21 is connected with the power mechanism 4. A feed pipe 5 is provided on the top side of the body 1 and close to the power mechanism 4. The bottom of the surface of the body 1 Corresponding two sides are provided with negative pressure slag removal mechanism 6, impurity removal device 3 is evenly distributed on the inner wall of the body 1 and is connected with the negative pressure slag removal mechanism 6, and the feed pipe ...

Embodiment example 2

[0037] The stirring mechanism 2 is provided with a rotating roller 21, a toggle device 22, and a helical blade 23. The rotating roller 21 is rotatably connected between the two sides corresponding to the top and bottom of the inner wall of the body 1, and the top of the rotating roller 21 penetrates the top of the inner wall of the body 1. And extending to the outside, the toggle device 22 is fixed on the surface of the rotating roller 21, the toggle device 22 is evenly distributed on the surface of the rotating roller 21, the helical blade 23 is fixed on the surface of the rotating roller 21 and is located at the bottom.

[0038] The toggle device 22 is provided with a stirring fan blade 221, a curved surface fin 222, a magnetic strip 223, and an elastic knocking device 224. One end of the stirring fan blade 221 is fixedly connected to the surface of the rotating roller 21, and the curved surface fin 222 is arranged on the stirring surface. The surface side of the fan blade 22...

Embodiment example 3

[0040] The elastic percussion device 224 is provided with a tension spring 2241 and a solid impact ball 2242. One end of the tension spring 2241 is fixedly connected to the interior of the stirring fan blade 221, and the surface of the solid impact ball 2242 is fixedly connected to one end of the tension spring 2241 away from the stirring fan blade 221. , the surface of the solid impact ball 2242 is matched and connected with the surface of the stirring fan blade 221. When the stirring fan blade 221 is driven by the rotating roller 2 to rotate, the elastic percussion device 224 also rotates, and then the solid impact ball 2242 is subjected to centrifugal force to be rotated. At this time, the tension spring 2241 is stretched, so that when the thrown solid impact ball 2242 rotates, it will impact the plate-type base 31, causing it to vibrate, and then the collected particulate impurities will be cleaned up to reduce The impurities stick together, which can achieve the effect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com