Shield segment local water pressure resistance detection device

A detection device and segment technology, applied in the liquid tightness measurement using liquid/vacuum degree, detecting the appearance of fluid at the leakage point, shaft equipment, etc., can solve the problem of groundwater influx, irregular prefabrication process and transportation process , river flooding and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

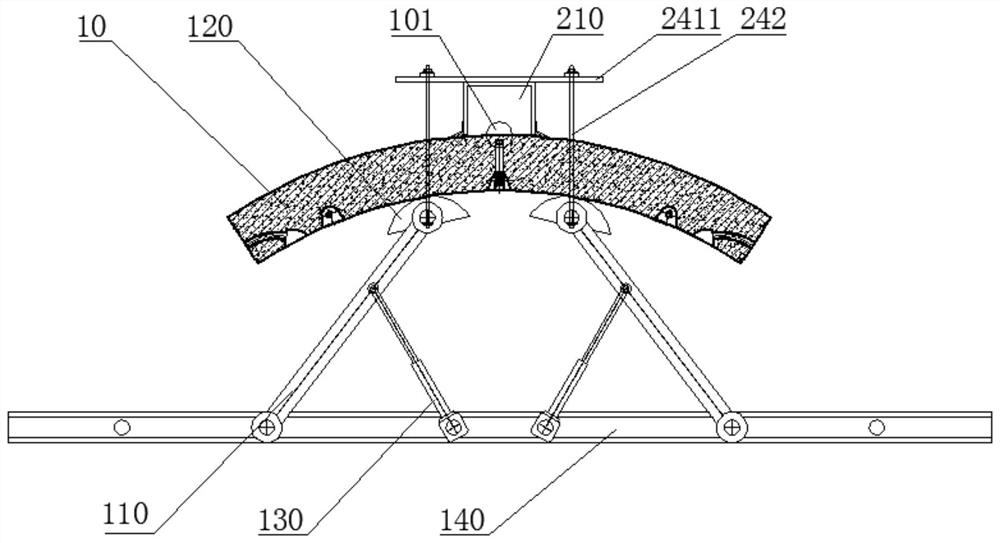

[0029] Aiming at the problems in the prior art, the embodiment of the present invention provides a device for detecting the local water pressure resistance of the segment for shield tunneling, the device comprising:

[0030] A support part, the support part includes at least two support columns supporting the segment from the bottom of the segment, and the distance between at least two support columns can be adjusted;

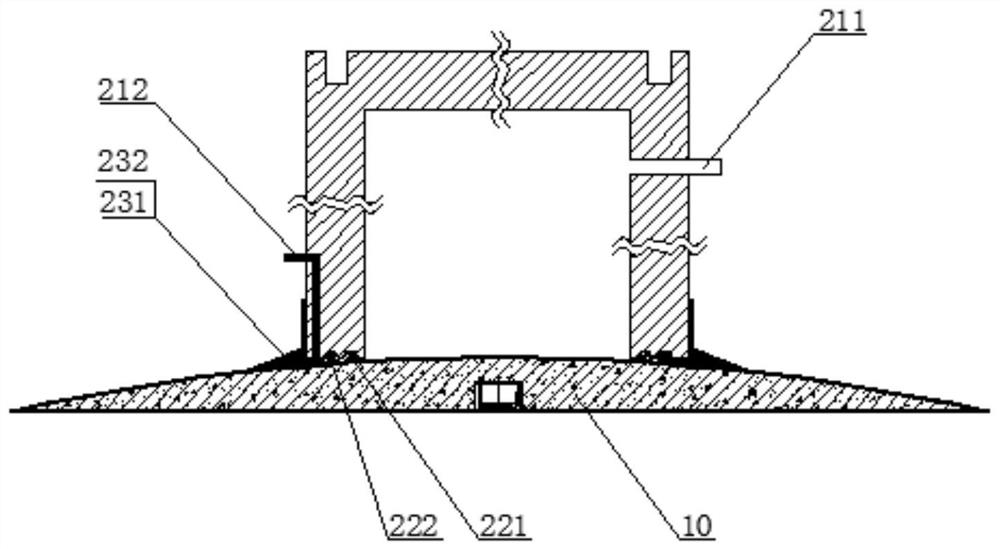

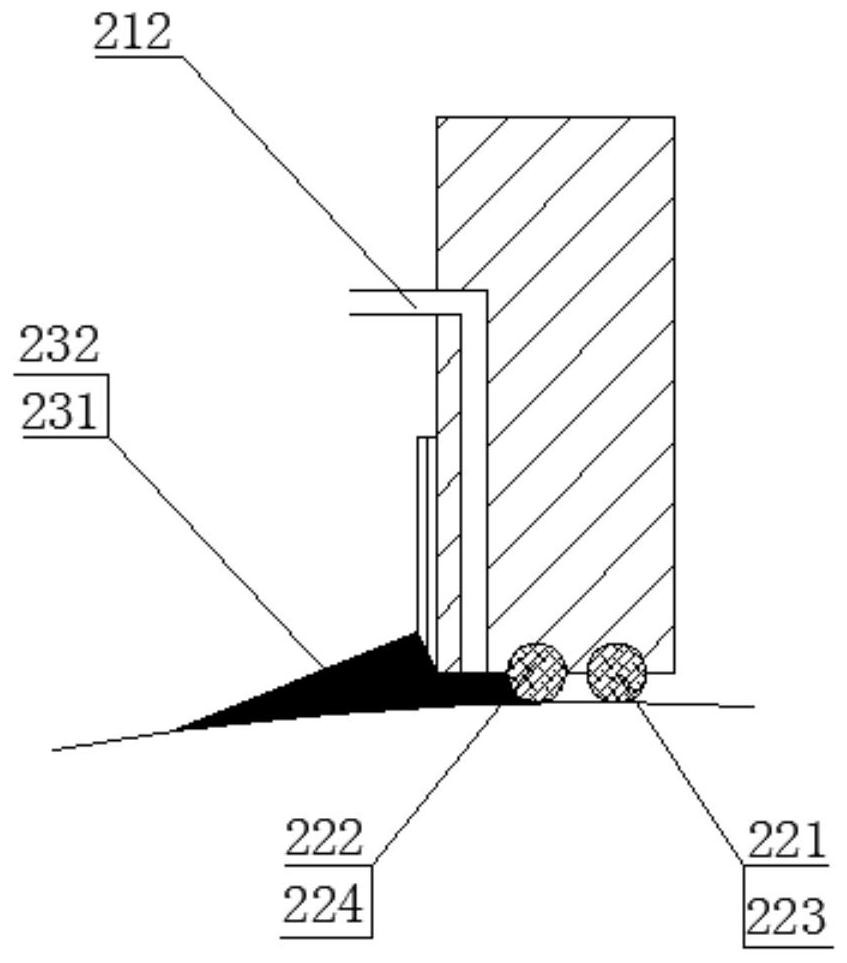

[0031] A water pressure loading part, the water pressure loading part includes a water pressure loading cup that is reversed and fixed on the part of the segment to be tested, and the cup end of the water pressure loading cup is attached to the outer wall of the segment; The water pressure loading part includes at least one water body injection port, and the water body injection port is arranged on the side wall or the top wall of the water pressure loading cup;

[0032] There is a sealed connection between the mouth end of the water pressure loaded cup and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com