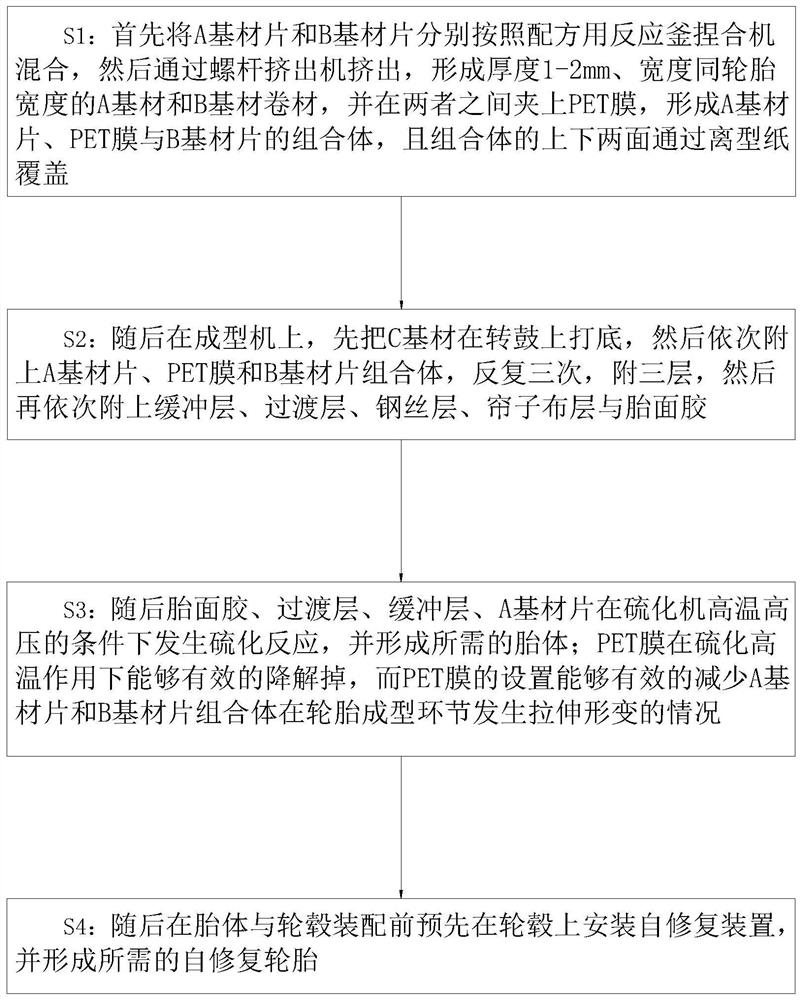

Preparation and process of a self-repairing safety tire

A safety tire and preparation technology technology, applied in tires, household appliances, other household appliances, etc., can solve problems such as changes and affect the stability of tire self-healing effect, so as to reduce tire blowouts, improve stability and safety, consistent quality results

Active Publication Date: 2022-05-31

江苏普利玛斯轮胎科技有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the tire is punctured, the internal viscous material will wrap the punctured object to prevent air leakage. When the punctured object is pulled out, the rubber material will instantly fill the formed gap, thereby realizing the function of automatic repair. Improve the safety of the tire, but this method needs to fill a large amount of rubber into the tire, and the performance of the rubber stored inside the tire will change with the change of the tire temperature, thus affecting the self-repair effect of the tire and the repair time. stability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment approach

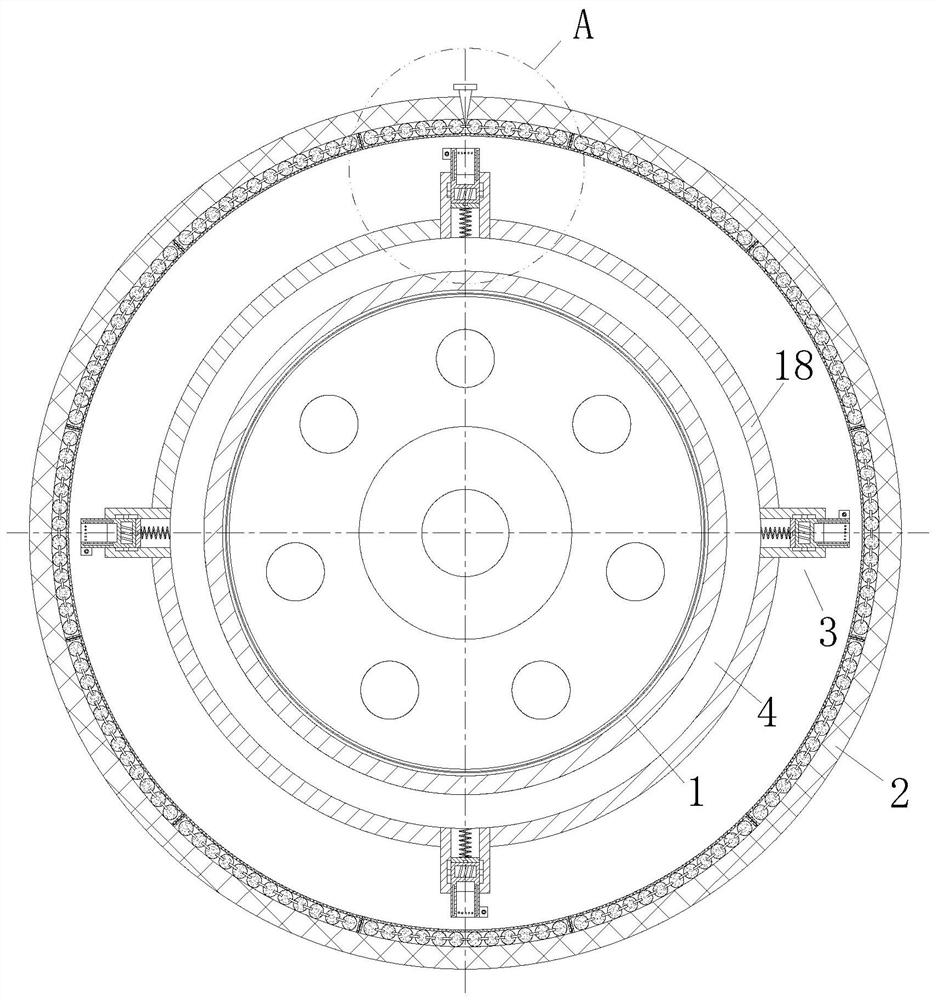

[0048] As an embodiment of the present invention, the cross-sectional shapes of the sliding cavity 5 and the limiting plate 10 are respectively ring shapes, and

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of tire preparation, and specifically relates to the preparation and process of a self-repairing safety tire. The tire includes a hub and a carcass. The hub is provided with a self-repairing device, which includes a rotating The side wall of the swivel ring is connected with a sliding cavity, and a sliding plate is slidably connected to the inside of the sliding cavity. An electric spray box is installed, and repair glue is stored inside the electric spray box, a discharge trough is arranged in the side wall of the repair chamber, inclined nozzles are arranged on the side wall of the repair chamber, and the outside of the slide plate The end is connected with a magnetic iron; by setting a self-repair device inside the tire, the present invention can realize fixed-point and efficient repair when foreign objects are stuck inside the carcass, so that the inside of the tire does not leak air, and at the same time, it can also reduce the situation of tire blowout , Improve the quality and working life of the tire.

Description

A kind of preparation and process of self-healing safety tire technical field The invention belongs to the technical field of tire preparation, specifically a kind of preparation and process with self-repairing safety tires. art. Background technique [0002] The current tire industry market is relatively large, and the competition is relatively large. People in the tire industry are constantly looking for new Roads, such as self-healing safety tires, generally have a special coating of rubber inside the tires. When the tire is punctured, The internal viscous material will wrap the inserted object to prevent air leakage, and when the inserted object is pulled out, the glue will instantly reduce the gap formed. Fill the mouth to realize the function of automatic repair, and at the same time to improve the safety of the tire, but this method requires the wheel The inside of the tire is filled with a large amount of rubber, and the performance of the rubber stored in ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29D30/06B29D30/08

CPCB29D30/0685B29D30/08B29D2030/0686Y02T10/86

Inventor 蒋凯朱渊

Owner 江苏普利玛斯轮胎科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com