Preparation process of self-repairing safety tire

A technology for safety tires and preparation technology, which is applied to tires, household appliances, and other household appliances, and can solve problems affecting the stability and changes of tire self-repair effects, so as to improve stability and safety, reduce tire blowouts, consistent quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

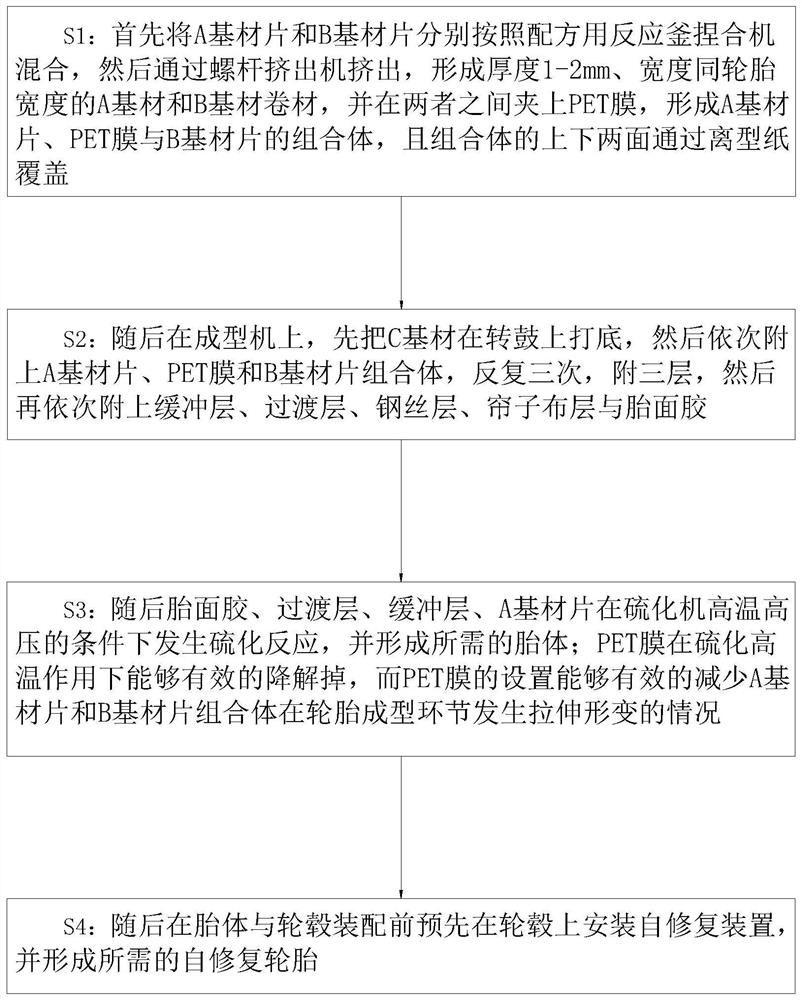

[0042] A preparation process with self-repairing safety tires, the process is applicable to the above-mentioned tires, the steps are as follows:

[0043] S1: Firstly, mix A base material sheet and B base material sheet respectively with a reaction kettle kneader according to the formula, and then extrude through a screw extruder to form A base material and B base material with a thickness of 1-2 mm and a width equal to the tire width Roll material, and sandwich PET film between the two to form a combination of A substrate sheet, PET film and B substrate sheet, and the upper and lower sides of the combination are covered by release paper;

[0044] S2: Then on the forming machine, base C base material on the drum first, then attach the combination of A base material sheet, PET film and B base material sheet in sequence, repeat three times, attach three layers, and then attach them in sequence Buffer layer, transition layer, steel wire layer, cord fabric layer and tread compound;...

Embodiment approach

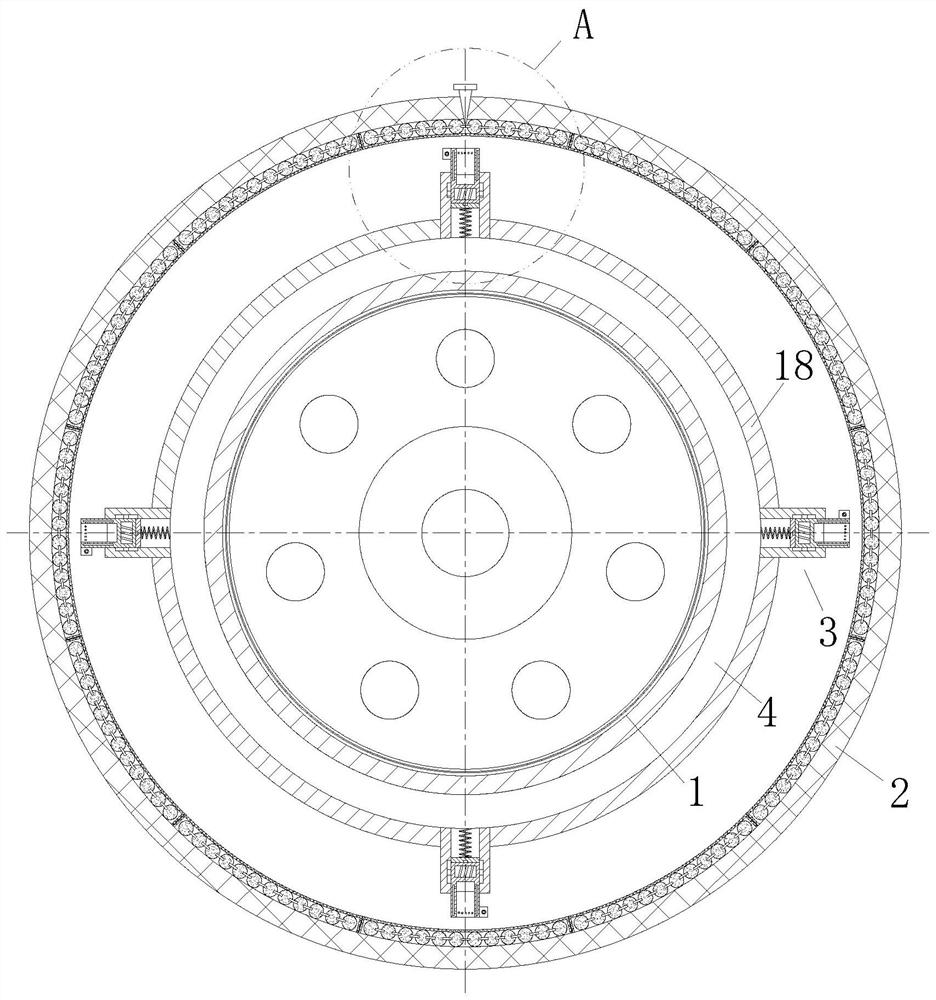

[0048] As an embodiment of the present invention, the cross-sectional shapes of the sliding chamber 5 and the limiting plate 10 are ring shapes respectively, and the outer end of the side wall of the sliding plate 6 is installed with a power block 15 communicating with the discharge groove 13 , the side wall of the power block 15 is provided with a nozzle 16 tangent to the side wall of the slide plate 6, and the bottom end of the slide plate 6 is rotatably connected with a bottom plate 17; when working, when the electric spray box 12 squeezes the repair glue inside At this time, a part of the repair glue can be ejected from the nozzle 16 and be tangent to the side wall of the slide plate 6, so that the repair glue can apply a rotating force to the slide plate 6 during the ejection process. At this time, the slide plate 6 is relatively When the bottom plate 17 rotates, it can drive the nozzle 14 to rotate and spray glue on the damaged position of the carcass 2, which further imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com