Sowing device for weak-gluten wheat planting

A technology for sowing device and wheat seeds, which is applied to sowing, fertilizing devices, parts of planters, etc., can solve the problems of reduced yield, low protein content, incompatibility with the characteristics of wheat growth, etc., and achieves the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

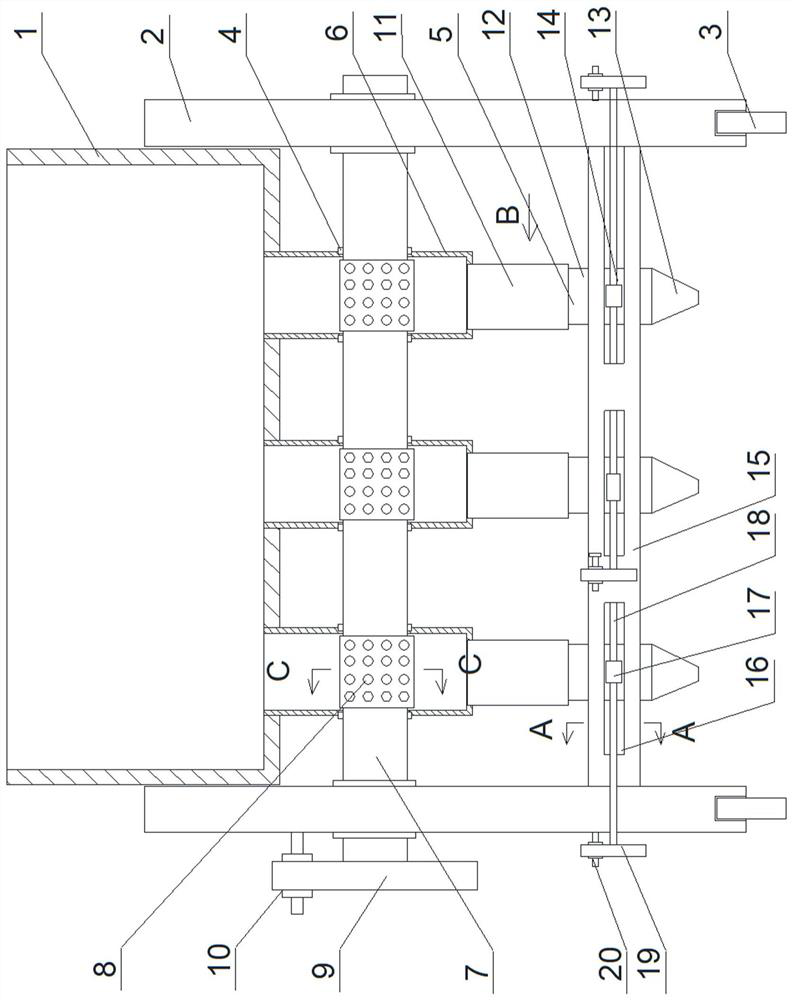

[0025] Such as Figure 1 to Figure 4 As shown, a seeding device for planting weak gluten wheat comprises a storage box 1, a support frame 2 fixedly connected to the side of the storage box 1, a roller 3 connected to the bottom of the support frame 2, and also includes The unloading mechanism 4 fixedly connected to the bottom of the material holding box 1, the discharge mechanism 5 fixedly connected to the bottom of the unloading mechanism 4, are located in the unloading mechanism 4 and are used to adjust the weak gluten wheat seeds The blanking adjustment mechanism for the blanking amount, the row spacing adjustment mechanism 14 for adjusting the row spacing of wheat, the weak-gluten wheat seeds in the storage box 1 pass through the blanking mechanism 4 and enter the discharge mechanism 5, and then enter the land and sow , the blanking adjustment mechanism is used to adjust the quantity of weak gluten wheat in the storage box 1 entering the discharge mechanism 5, thereby reali...

Embodiment 2

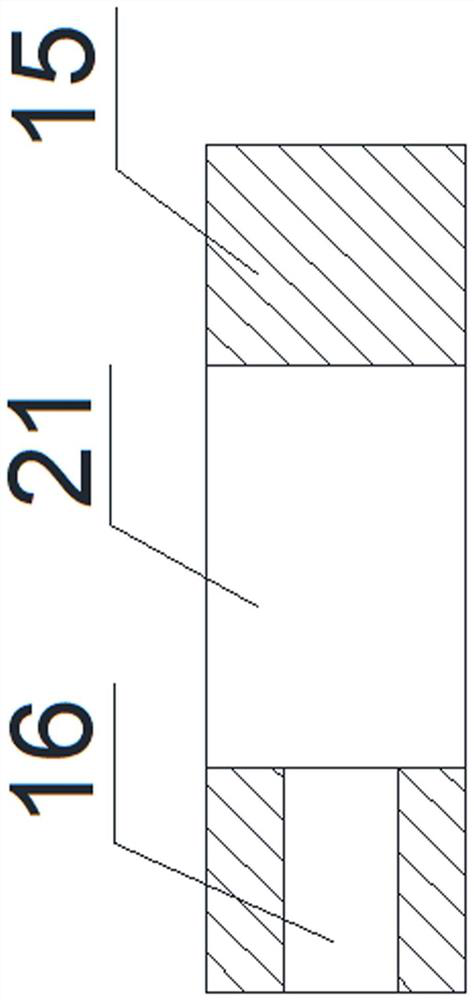

[0032] Such as Figure 5 , figure 2 and image 3 As shown, a seeding device for planting weak gluten wheat comprises a storage box 1, a support frame 2 fixedly connected to the side of the storage box 1, a roller 3 connected to the bottom of the support frame 2, and also includes The unloading mechanism 4 fixedly connected to the bottom of the material holding box 1, the discharge mechanism 5 fixedly connected to the bottom of the unloading mechanism 4, are located in the unloading mechanism 4 and are used to adjust the weak gluten wheat seeds The blanking adjustment mechanism for the blanking amount, the row spacing adjustment mechanism 14 for adjusting the row spacing of wheat, the weak-gluten wheat seeds in the storage box 1 pass through the blanking mechanism 4 and enter the discharge mechanism 5, and then enter the land and sow , the blanking adjustment mechanism is used to adjust the quantity of weak gluten wheat in the storage box 1 entering the discharge mechanism 5...

Embodiment 3

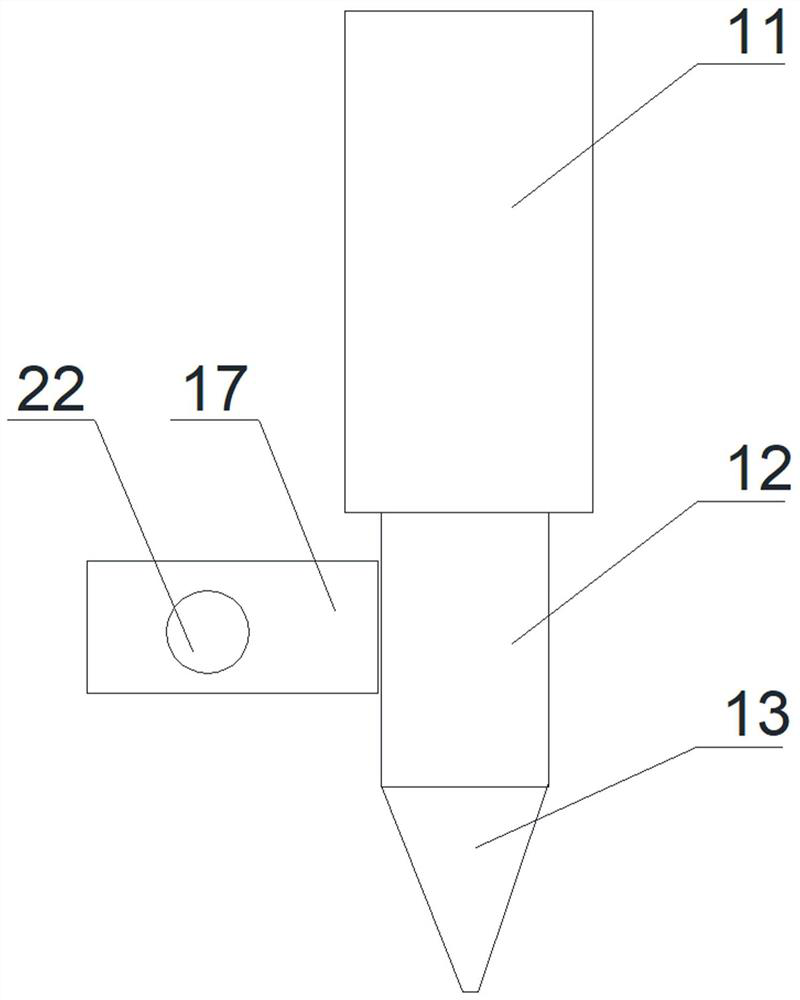

[0038] Such as Figure 6 As shown, a seeding device for planting weak gluten wheat comprises a storage box 1, a support frame 2 fixedly connected to the side of the storage box 1, a roller 3 connected to the bottom of the support frame 2, and also includes The unloading mechanism 4 fixedly connected to the bottom of the material holding box 1, the discharge mechanism 5 fixedly connected to the bottom of the unloading mechanism 4, are located in the unloading mechanism 4 and are used to adjust the weak gluten wheat seeds The blanking adjustment mechanism for the blanking amount, the row spacing adjustment mechanism 14 for adjusting the row spacing of wheat, the weak-gluten wheat seeds in the storage box 1 pass through the blanking mechanism 4 and enter the discharge mechanism 5, and then enter the land and sow , the blanking adjustment mechanism is used to adjust the quantity of weak gluten wheat in the storage box 1 entering the discharge mechanism 5, thereby realizing the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com