Preparation method and production device of instant wheat germs

A technology for wheat germ and production equipment, which is applied in the field of ready-to-eat wheat germ preparation, can solve the problems of age groups and people who cannot achieve taste and quality, cannot improve consumption, complicated processes, etc. , the effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

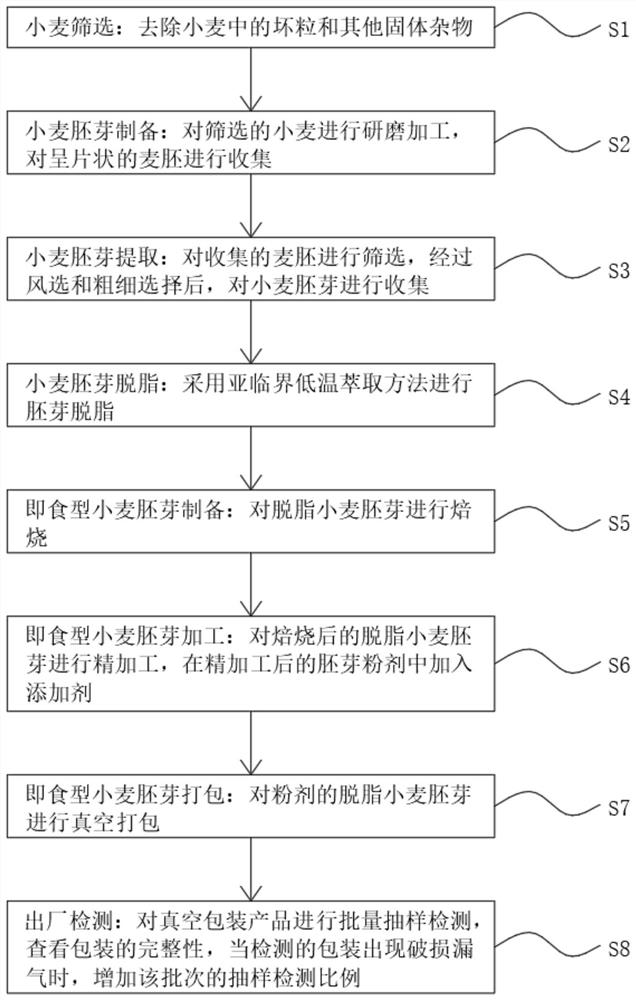

[0044] Such as figure 1 As shown, the invention provides technical scheme, a kind of instant type wheat germ preparation method, comprises the following steps:

[0045] S1. Wheat screening: remove bad grains and other solid impurities in wheat;

[0046] S2. Preparation of wheat germ: grinding the screened wheat, and collecting the flake wheat germ;

[0047] S3. Wheat Germ Extraction: Screen the collected wheat germ, and collect the wheat germ after wind selection and thickness selection;

[0048] S4. Degreasing of wheat germ: degreasing of germ by subcritical low-temperature extraction method;

[0049] S5. Preparation of ready-to-eat wheat germ: roasting the defatted wheat germ;

[0050] S6. Processing of ready-to-eat wheat germ: finishing the roasted defatted wheat germ, adding additives to the refined germ powder;

[0051] S7. Packing of ready-to-eat wheat germ: vacuum packing the defatted wheat germ of the powder;

[0052]S8. Ex-factory inspection: carry out batch samp...

Embodiment 2

[0061] Such as figure 1 As shown, the invention provides technical scheme, a kind of instant type wheat germ preparation method, comprises the following steps:

[0062] S1. Wheat screening: remove bad grains and other solid impurities in wheat;

[0063] S2. Preparation of wheat germ: grinding the screened wheat, and collecting the flake wheat germ;

[0064] S3. Wheat Germ Extraction: Screen the collected wheat germ, and collect the wheat germ after wind selection and thickness selection;

[0065] S4. Degreasing of wheat germ: degreasing of germ by subcritical low-temperature extraction method;

[0066] S5. Preparation of ready-to-eat wheat germ: roasting the defatted wheat germ;

[0067] S6. Processing of ready-to-eat wheat germ: finishing the roasted defatted wheat germ, adding additives to the refined germ powder;

[0068] S7. Packing of ready-to-eat wheat germ: vacuum packing the defatted wheat germ of the powder;

[0069] S8. Ex-factory inspection: carry out batch sam...

Embodiment 3

[0078] Such as figure 1 As shown, the invention provides technical scheme, a kind of instant type wheat germ preparation method, comprises the following steps:

[0079] S1. Wheat screening: remove bad grains and other solid impurities in wheat;

[0080] S2. Preparation of wheat germ: grinding the screened wheat, and collecting the flake wheat germ;

[0081] S3. Wheat Germ Extraction: Screen the collected wheat germ, and collect the wheat germ after wind selection and thickness selection;

[0082] S4. Degreasing of wheat germ: degreasing of germ by subcritical low-temperature extraction method;

[0083] S5. Preparation of ready-to-eat wheat germ: roasting the defatted wheat germ;

[0084] S6. Processing of ready-to-eat wheat germ: finishing the roasted defatted wheat germ, adding additives to the refined germ powder;

[0085] S7. Packing of ready-to-eat wheat germ: vacuum packing the defatted wheat germ of the powder;

[0086] S8. Ex-factory inspection: carry out batch sam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap