A device and construction method for ensuring that the pile ends of prefabricated piles enter the bearing layer

A technology of prefabricated piles and bearing layers, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low implantation efficiency and achieve the effect of improving the low implantation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

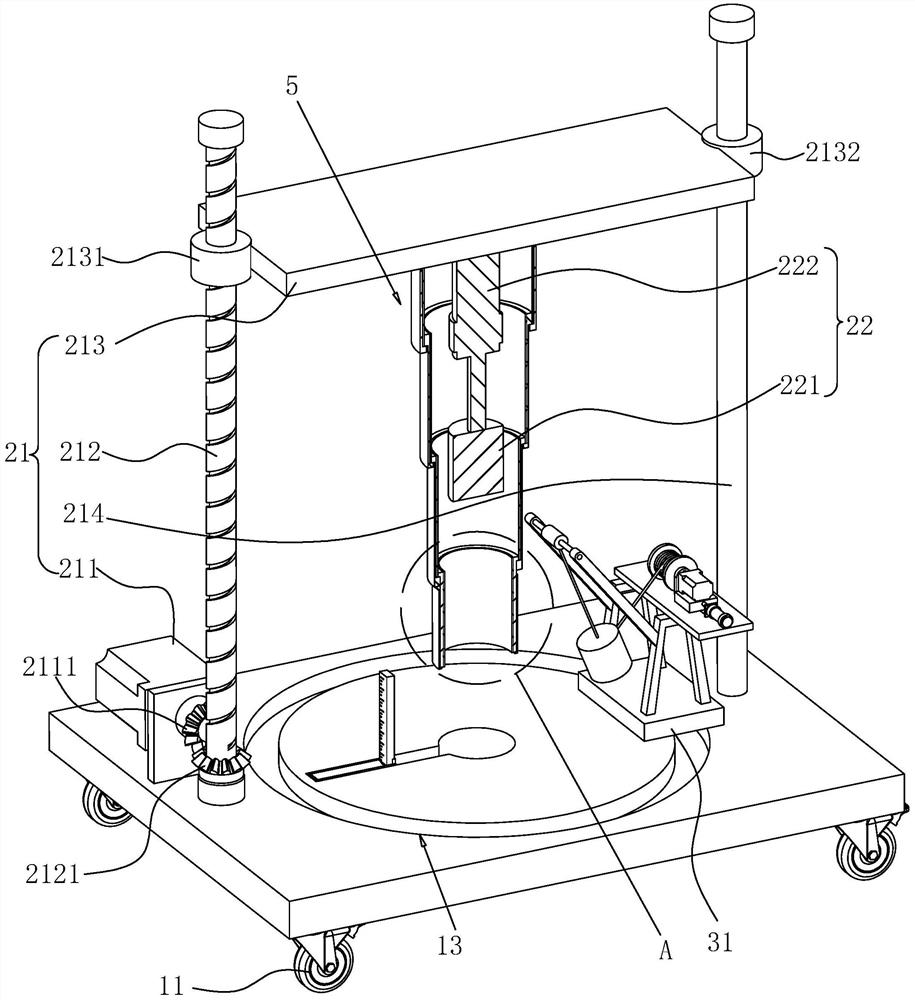

[0041] The following is attached Figure 1-5 The application is described in further detail.

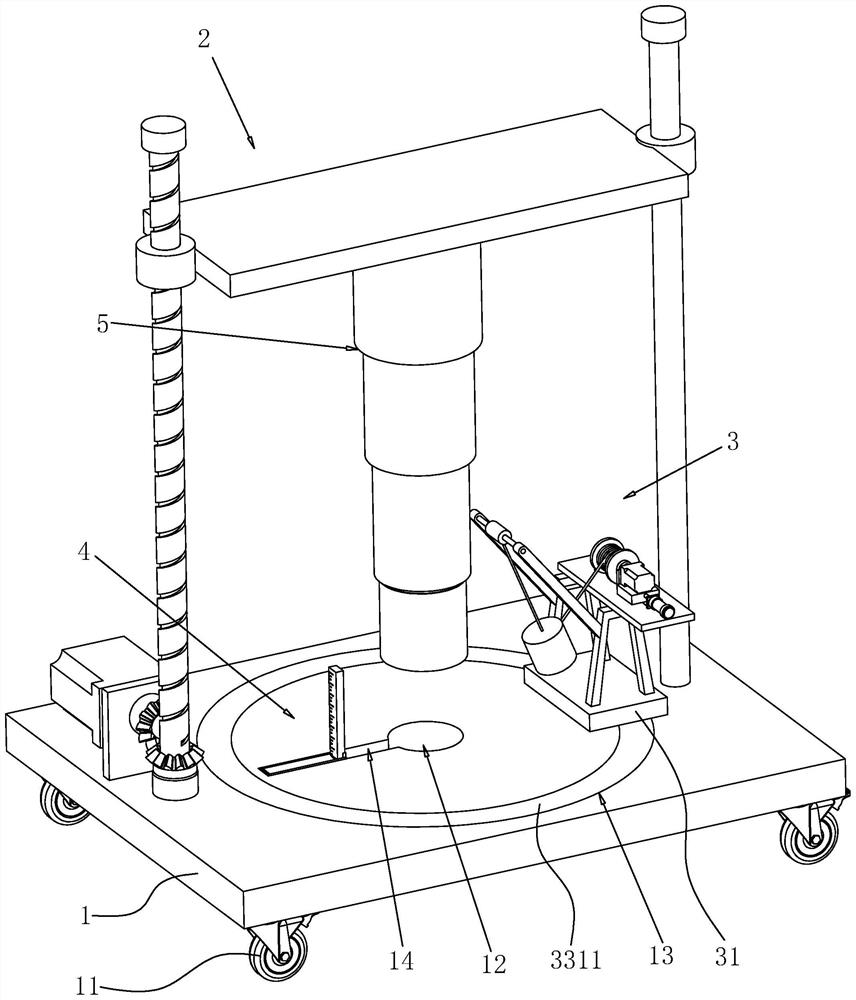

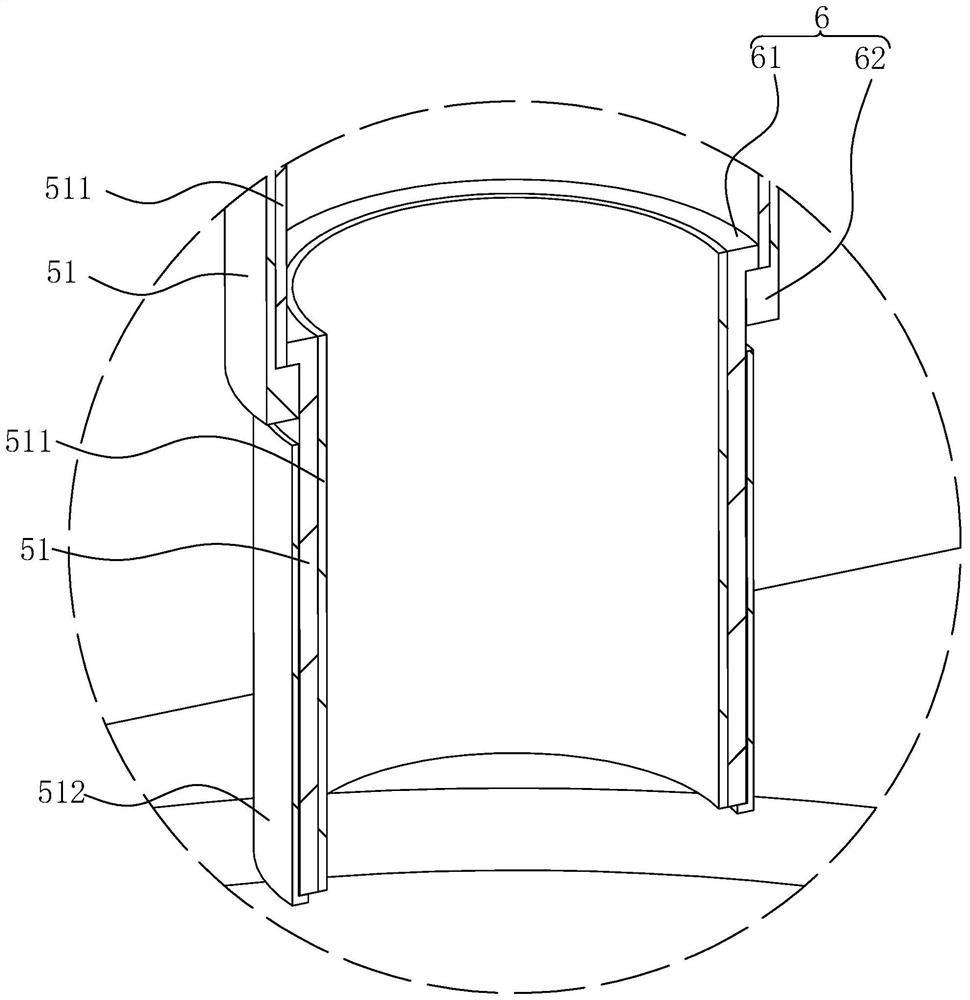

[0042] The embodiment of the present application discloses a device for ensuring that the pile ends of prefabricated piles enter the bearing layer. refer to figure 1 The device for ensuring that the prefabricated pile ends enter the load-bearing layer includes a base 1, a plurality of self-locking universal wheels 11 are arranged on the side facing the ground on the base 1, and a positioning hole 12 for the prefabricated pile to pass is opened on the base 1 , the shape of the positioning hole 12 is circular, and the aperture of the positioning hole 12 is larger than the diameter of the prefabricated pile; the base 1 is provided with a vertical hammering device 2, and the vertical hammering device 2 is used to hammer the prefabricated pile vertically downward Bearing layer; the base 1 is also provided with an offset correction device 3, which is used to correct the pile body of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com