Electric connection terminal, wiring structure of electric equipment, and relay socket

A technology of wiring structure and electrical equipment, applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problems of cumbersome installation procedures, many installation tools, broken wiring screws, etc., to simplify wiring operations, simple wiring methods, and suitable for wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

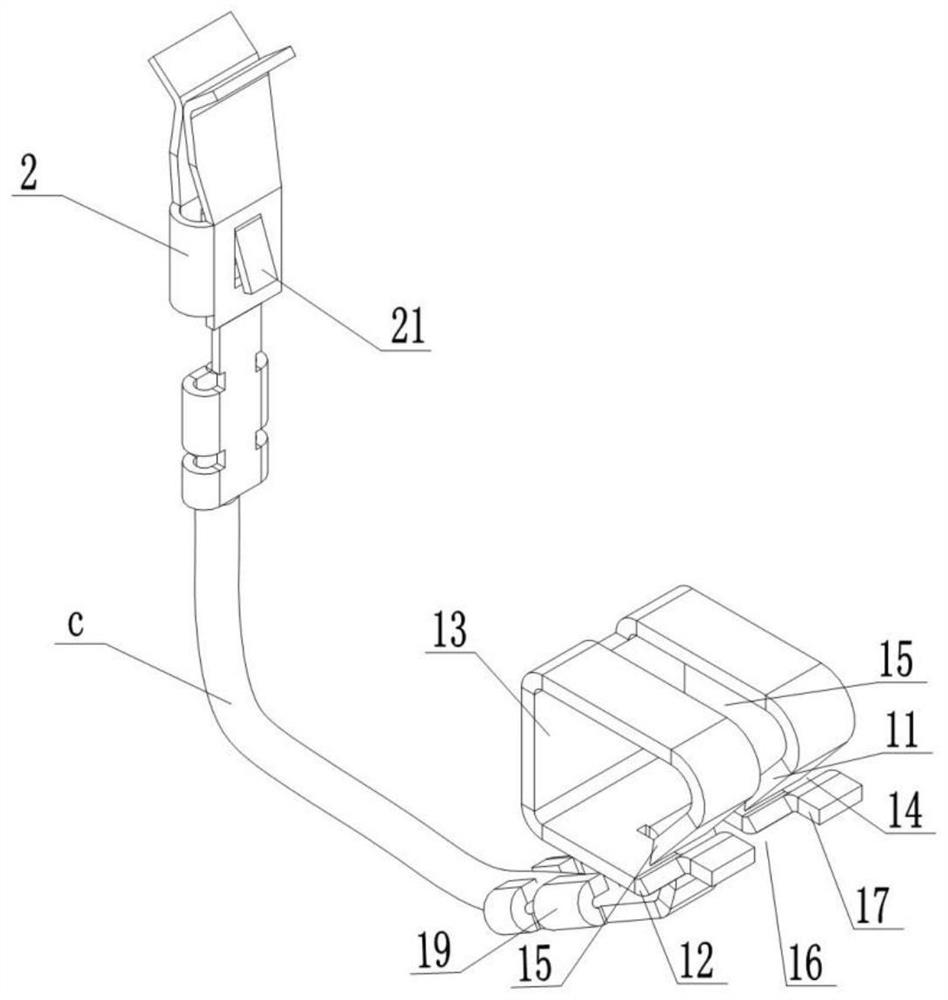

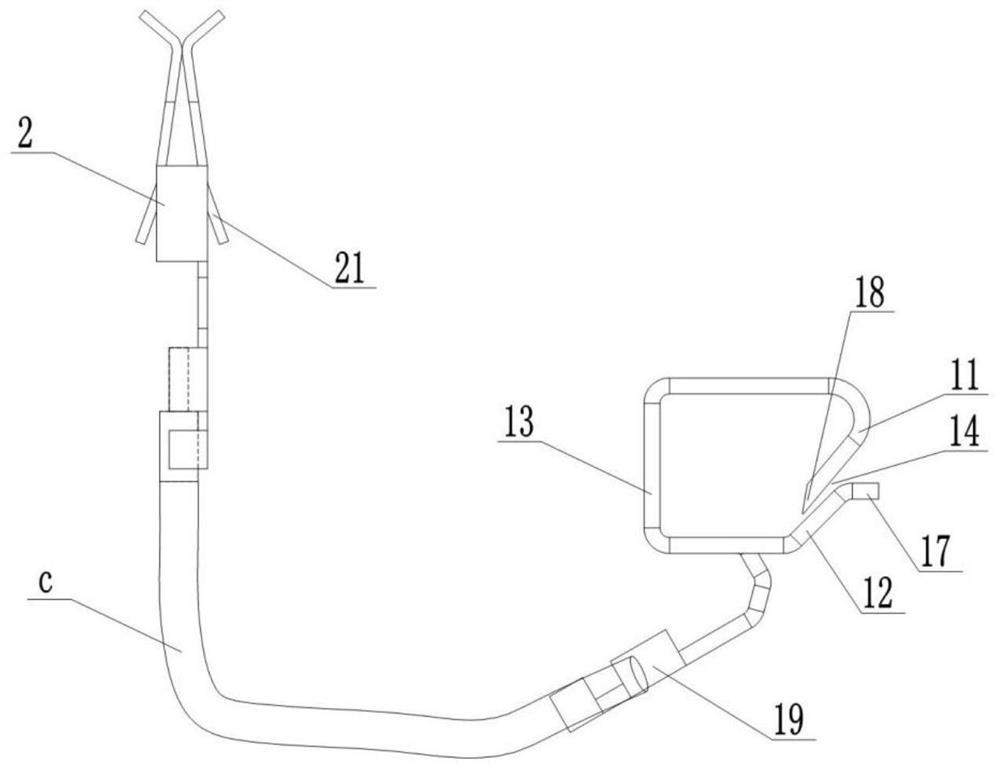

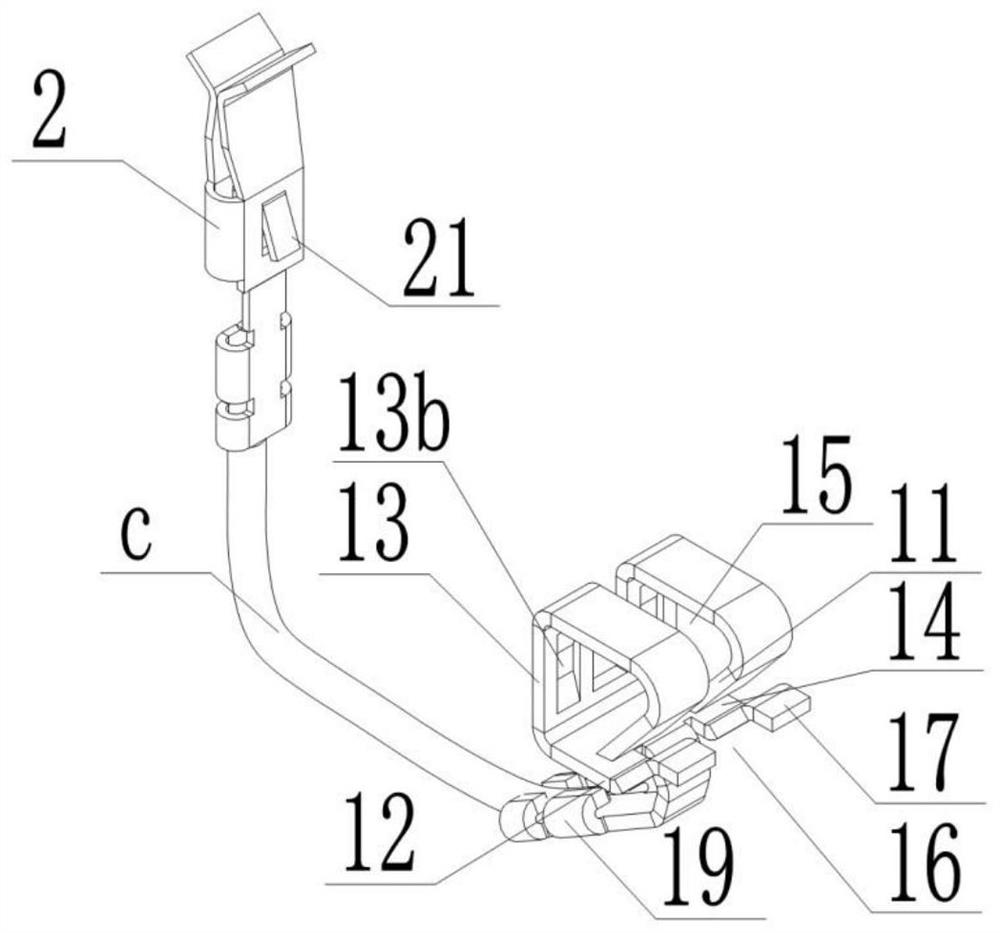

[0046] The following is attached Figures 1 to 22 The given examples further illustrate specific implementations of an electrical connection terminal and a relay socket of the present invention. An electrical connection terminal and a relay socket of the present invention are not limited to the description of the following embodiments.

[0047] An electrical connection terminal, comprising a terminal block 1 and a clamp spring 2, the terminal block 1 is electrically connected to the clamp spring 2, the terminal block 1 includes an integrally formed first clamping end 11, an elastic section 13 and a The second clamping end 12, the first clamping end 11 and the second clamping end 12 of the terminal block 1 are folded back and opposite, and a wiring gap 14 is formed between the first clamping end 11 and the second clamping end 12; When the elastic section 13 is deformed by operating the terminal block 1 through the operating member, the first clamping end 11 and the second clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com