A built-in tool magazine automatic protective door

An automatic protection and built-in technology, applied in the field of CNC machine tools, can solve the problems of poor sealing, easy to get stuck, no opening test, etc., and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

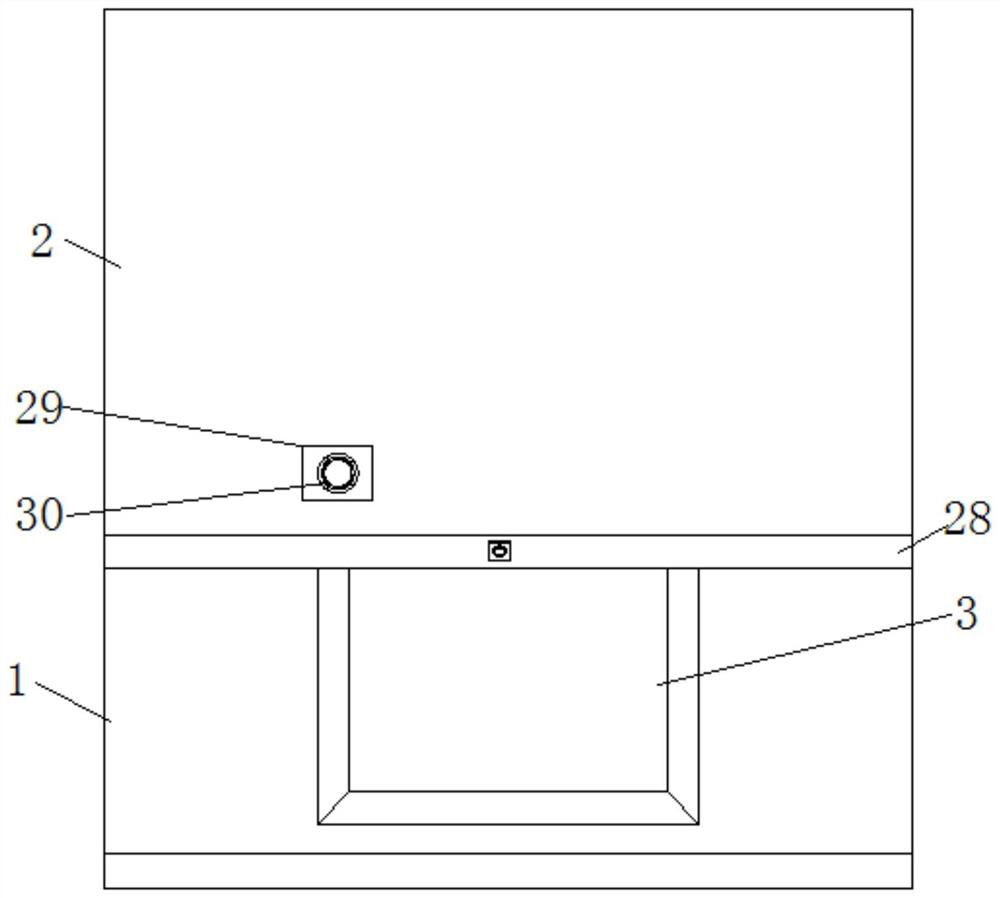

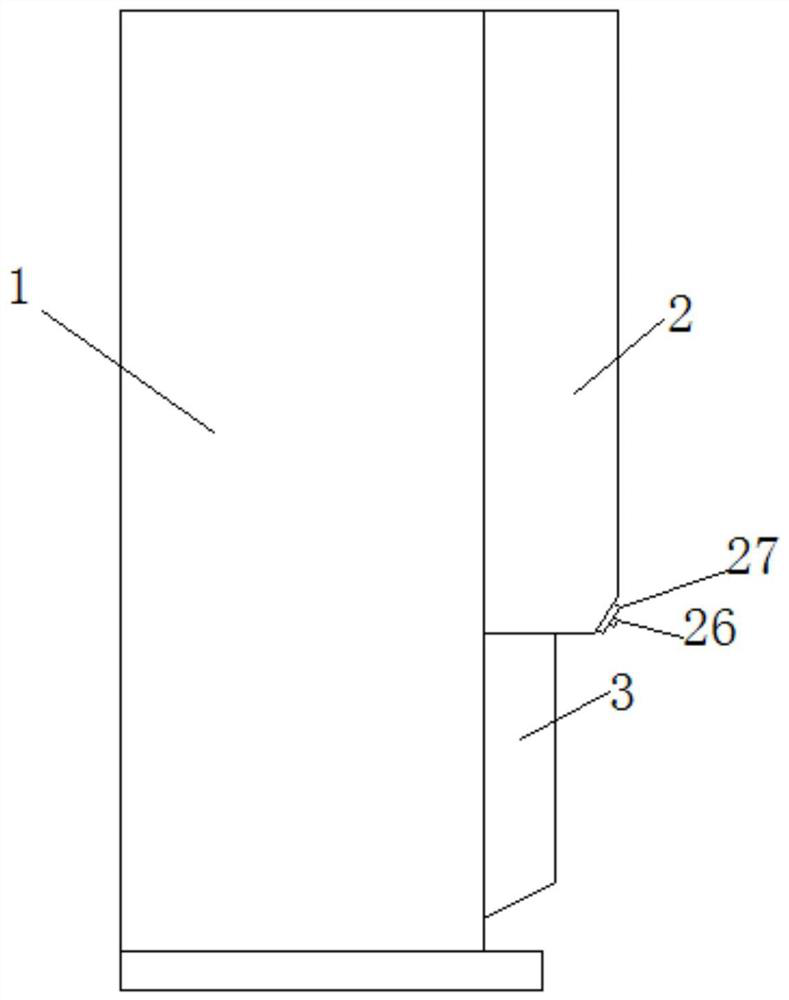

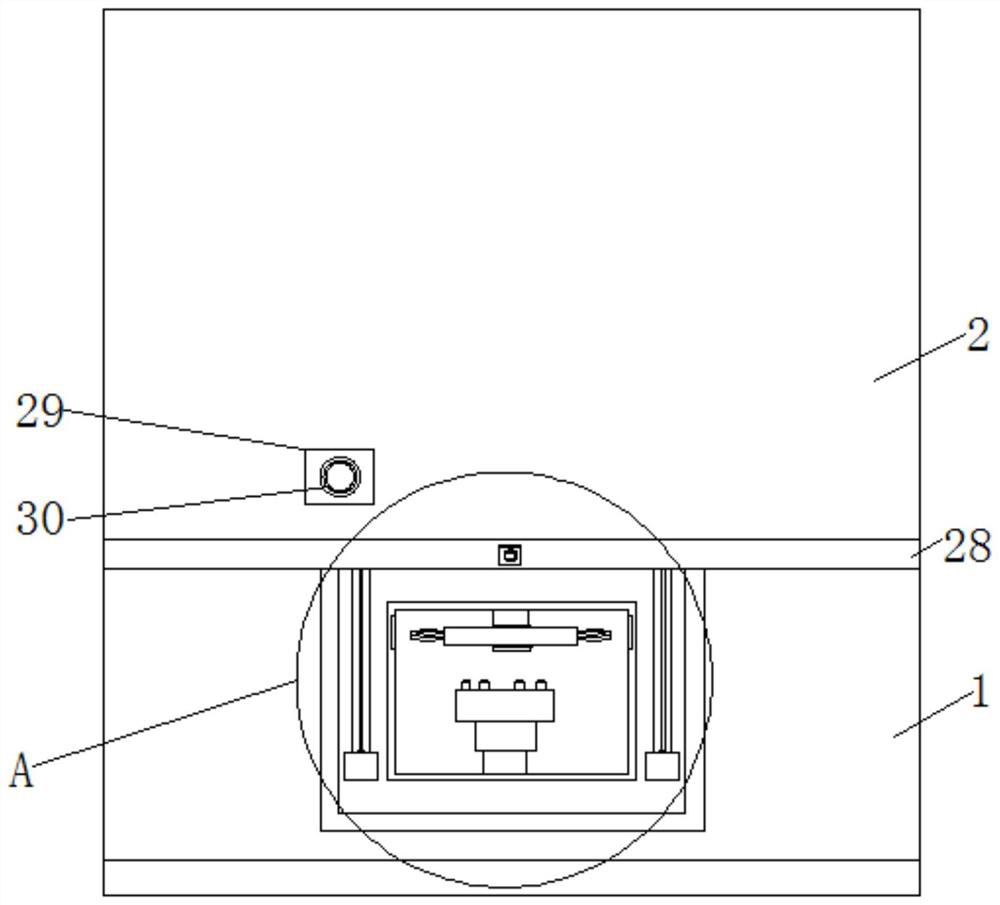

[0034] Such as Figure 1-9 As shown, the embodiment of the present invention provides an intrinsic knife library automatic guard door, including the inner-hidden knife library 1, the front wall of the inner tibial karrin 1 is provided with a guard plate 2, a toolkolder 4, and a protective plate 2 fixedly connected. The front wall of the Tibetan knife is adjacent to the top, and the switching knife port 4 is disposed on the front wall of the inner tool 2 and located on the guard 2, the inside of the toolkhead 4 is provided with the first induction device, the guard 2 front wall fixed connection with lamp Block 29, the front wall of the lamp holder 29 is fixedly connected to the alarm lamp 30, the lower end of the guard 2 is provided with the second inclined side 28, and the second inclined side 28 front wall is fixedly connected to the door trigger device, the inner hidden knife library 1 and the protective plate 2 Slide between the automatic door 3, the automatic door 3 cover the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com