An electrically driven metal wire skeleton-spandex fiber twisted composite artificial muscle and preparation method thereof

A spandex fiber and artificial muscle technology, which is applied in the manufacture of tools, program-controlled manipulators, manipulators, etc., can solve the problems of reduced load capacity and limited application of artificial muscles, and achieve large untwisting torque, low driving temperature, and high untwisting turns many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. It should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. The operation method without specifying the specific conditions in the following examples is usually in accordance with the conventional conditions, or in accordance with the conditions suggested by the manufacturer.

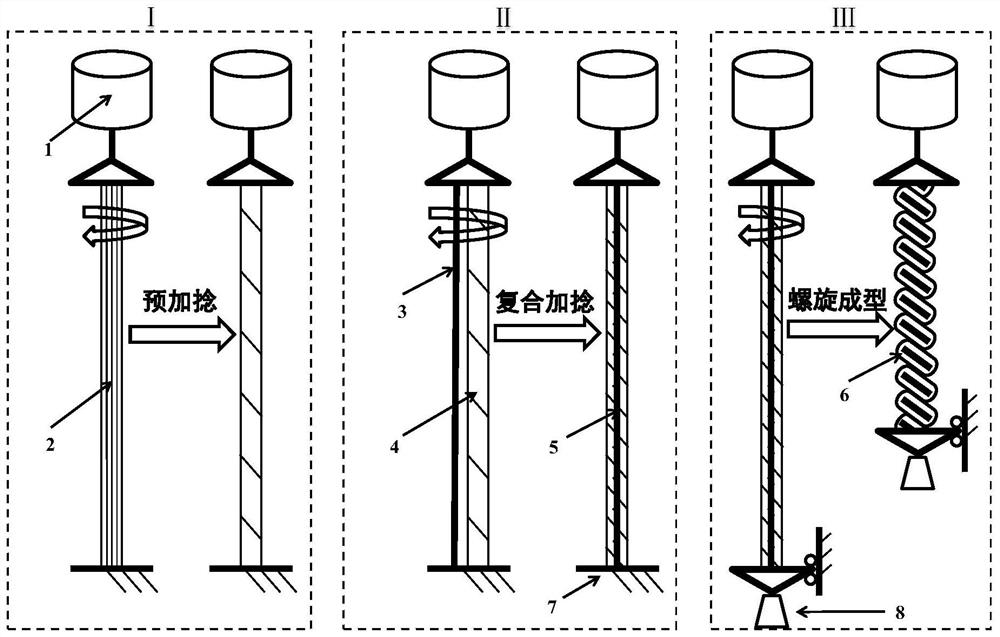

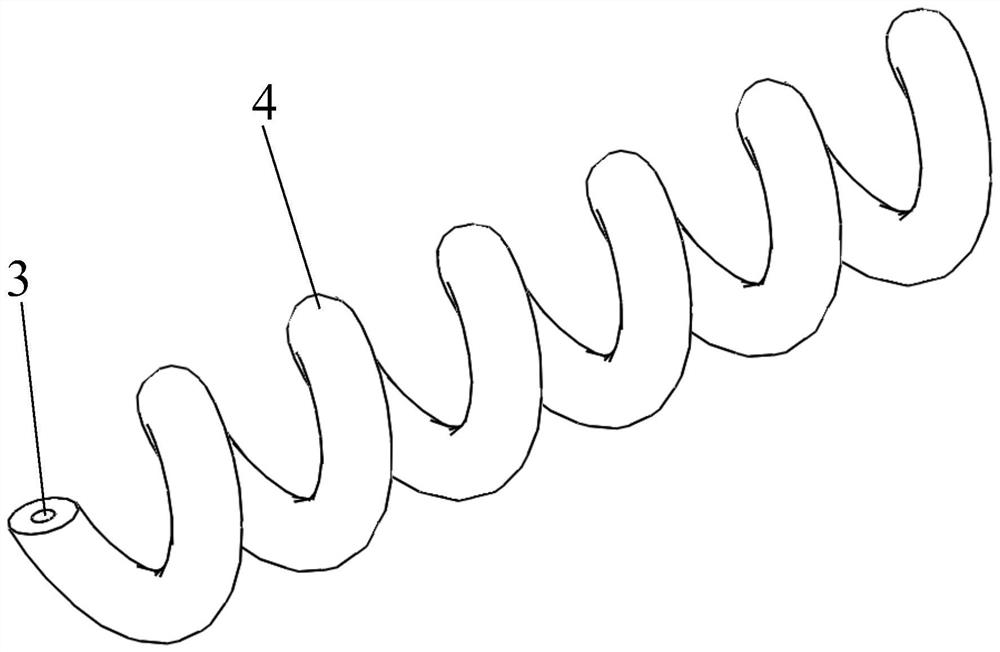

[0047] like figure 1 As shown, the preparation method of the electrically driven metal wire skeleton-spandex fiber twisted composite artificial muscle of the present embodiment includes the steps:

[0048] (1) Pretreatment stage: pre-stretching the spandex fiber bundle, then fixing one end of the pre-stretching spandex fiber 2, and pre-twisting the pre-stretching spandex fiber 2 at the other end under the action of the motor 1.

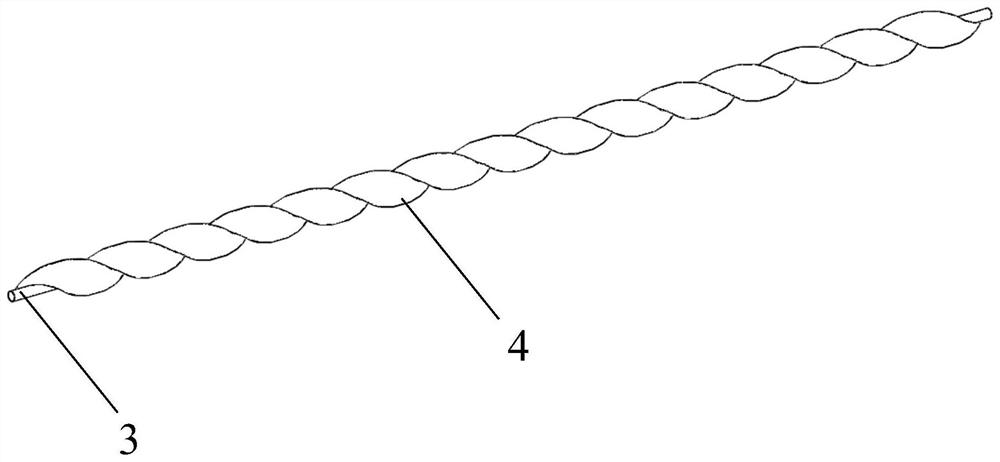

[0049] (2) Composite stage: with one end fixed, the other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com