Joint structure with steel support serving as steel replacement support and construction method

A technology of node structure and construction method, applied in basic structure engineering, excavation, construction, etc., can solve the problem of cumbersome construction process of support structure, and achieve the effect of avoiding secondary construction, ensuring the safety of foundation pit, and saving construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

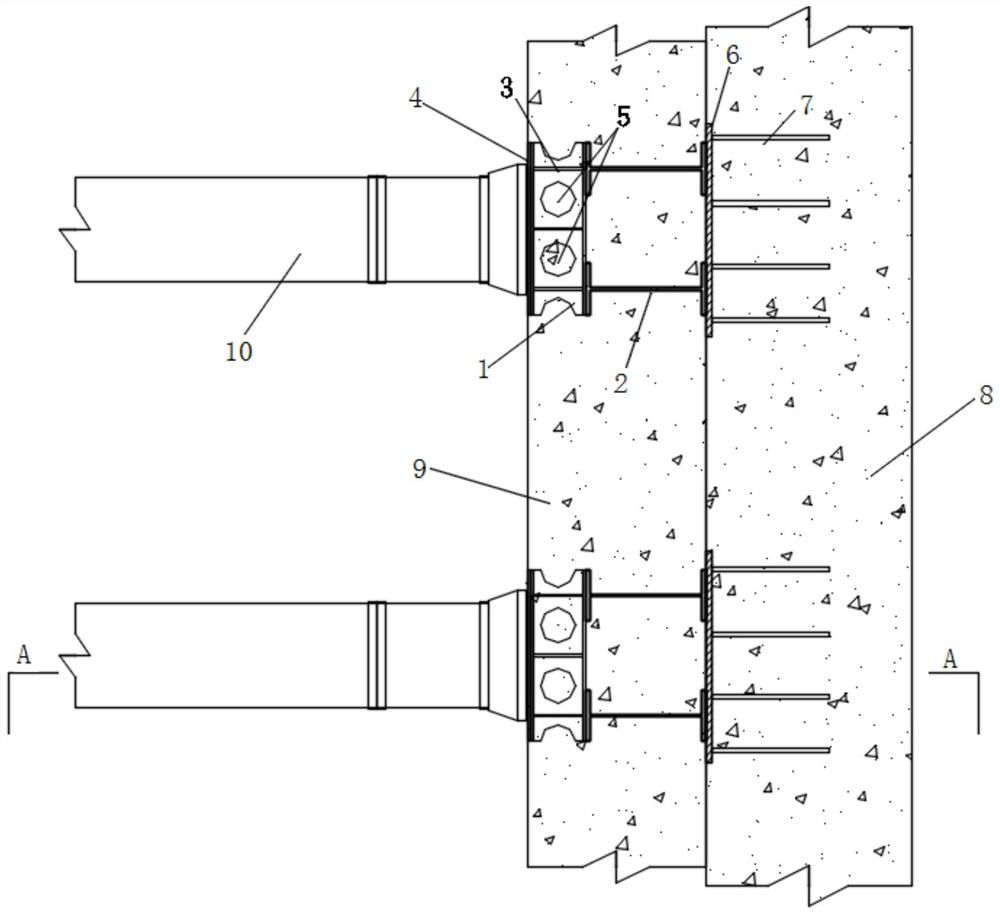

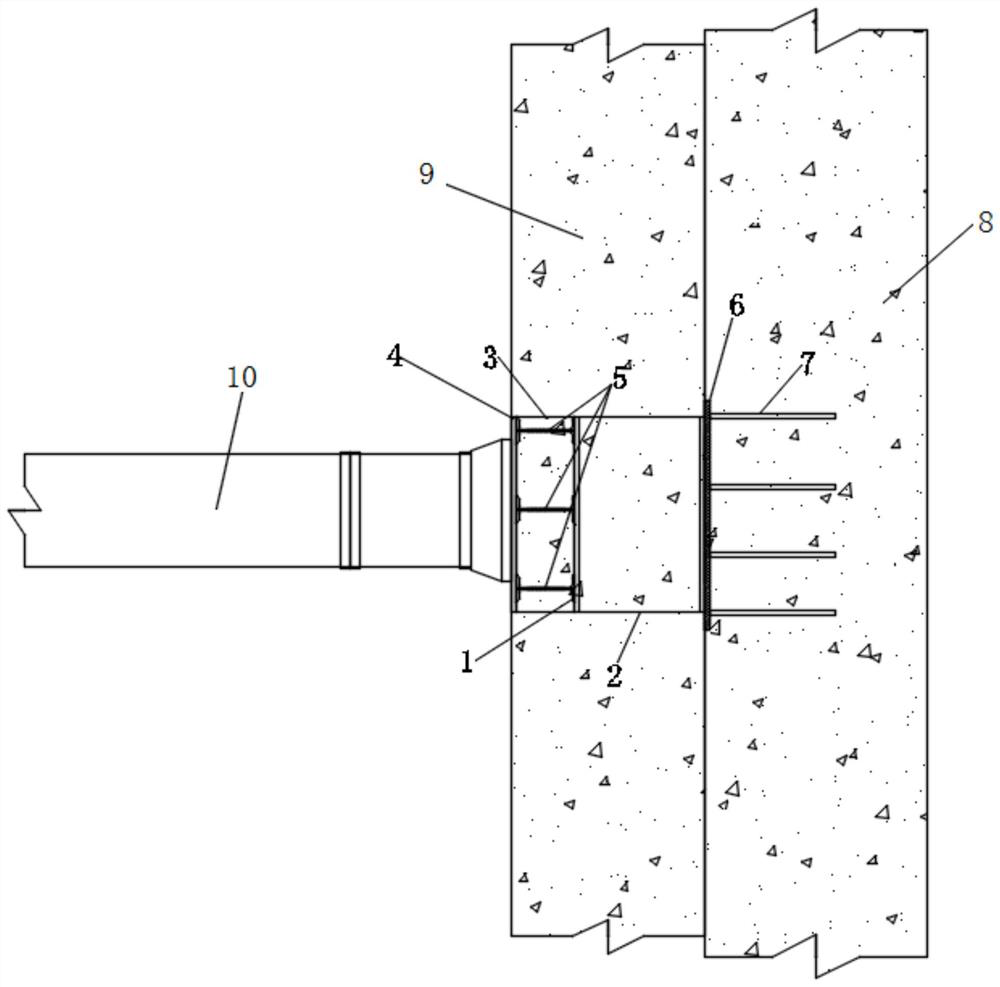

[0027] Such as figure 1 and figure 2 As shown, the steel support of the present invention doubles as a node structure for steel support, and is arranged in the side wall 9 between the end of the steel support 10 and the underground diaphragm wall 8. A connecting piece and a second connecting piece fixed to the first connecting piece, the second connecting piece abutting against the end of the steel support 10 .

[0028] By setting the node structure between the steel support 10 and the underground diaphragm wall 8, the steel support 10 does not need to be removed when the side wall 9 is constructed inside the foundation pit, and the side wall 9 can be poured directly without removing the steel support 10. The side wall 9 is poured again, and the steel is reinstalled after the concrete is solidified to change the support, and other constructions in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com