An automatic control cutting machine for construction

A cutting machine and aspect technology, applied in the field of road construction equipment and construction, can solve the problems of incomplete cutting, speed up construction progress, overcutting of roads, etc., achieve the effect of simple and reasonable structure, and avoid secondary construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

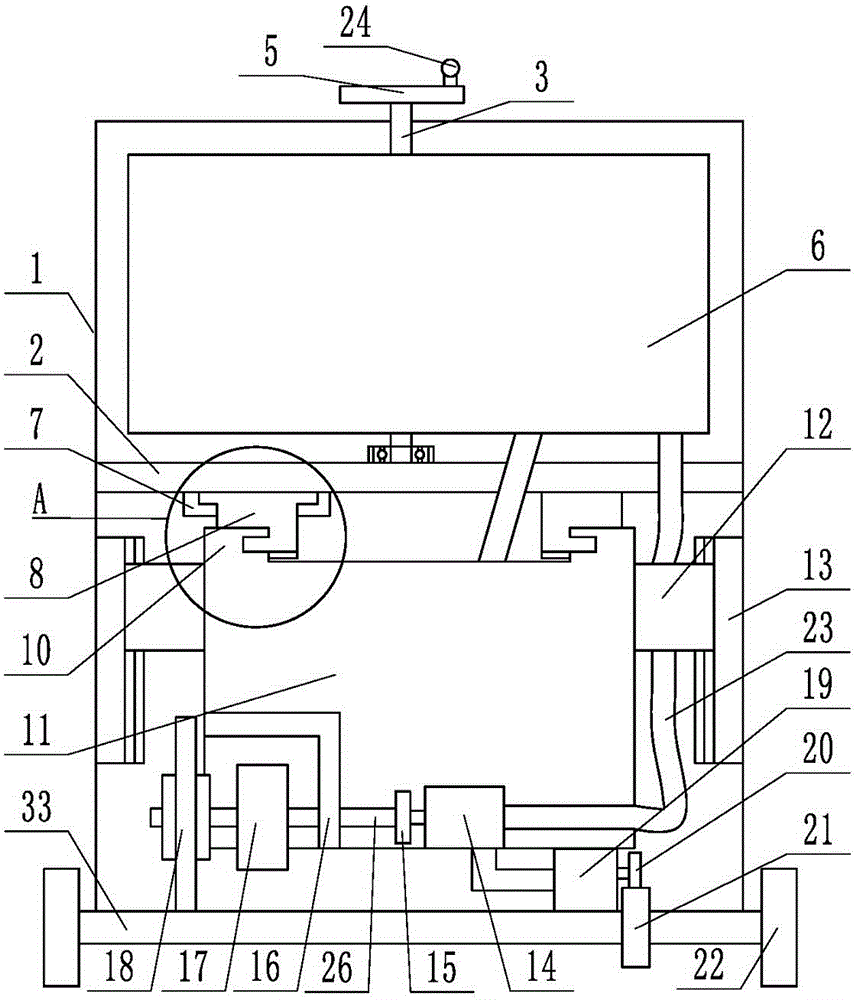

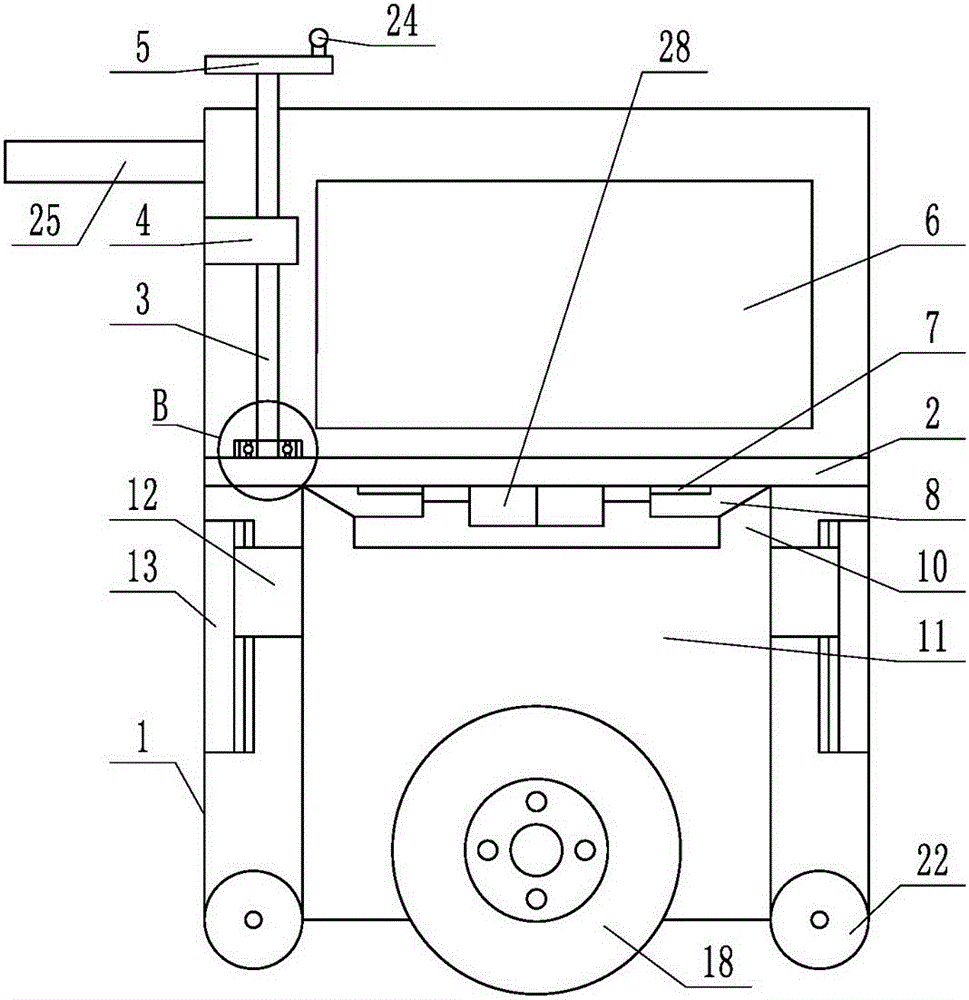

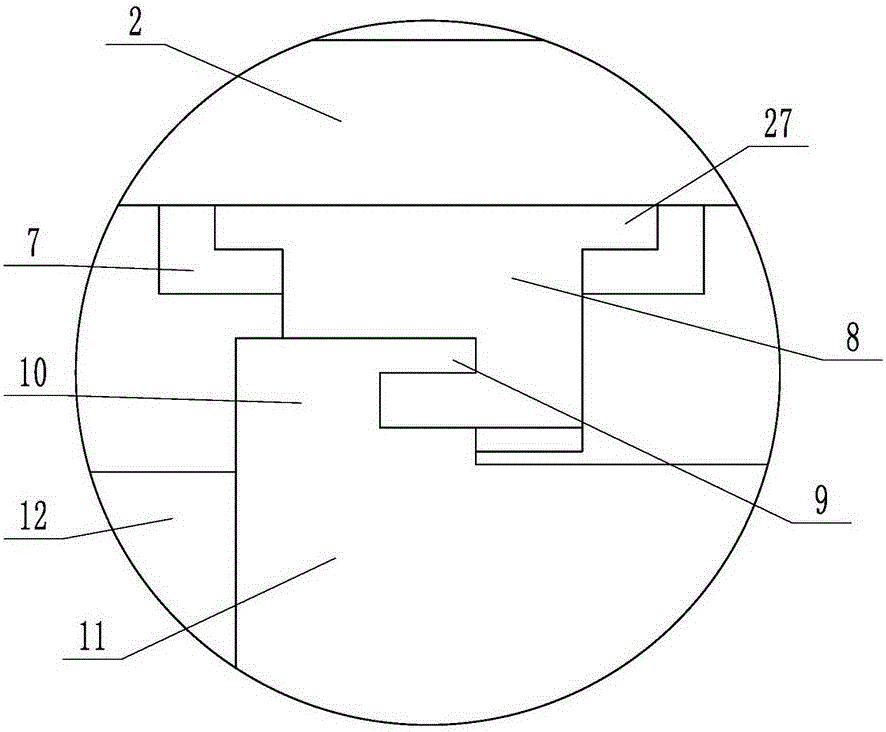

[0016] Depend on Figure 1 to Figure 7 Given, the present invention comprises frame 1, is characterized in that, frame 1 is horizontally provided with board 2 in the middle, is connected with lead screw 3 that protrudes from the top of frame 1 on the board 2, and lead screw 3 is fixed by fixing block 4 In the frame 1, a turntable 5 is provided on the top of the lead screw 3, which constitutes a structure in which the operation turntable 5 rotates and controls the movement of the strap 2 up and down. The frame 1 is provided with a small hydraulic station 6 located on the strap 2, and the strap 2 is lowered. A plurality of "T" grooves 7 are fixed on the side, and wedge blocks 8 are connected in the "T" grooves 7, and a hydraulic cylinder 28 connected to the tail of the wedge blocks 8 is installed on the lower side of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com