Water conservancy project waterproof roll construction method

A waterproofing membrane and construction method technology, applied in water conservancy engineering, marine engineering, infrastructure engineering and other directions, can solve the problem of inability to realize folding treatment, inability to simultaneously lay and smooth the waterproofing membrane, and inability to remove excess air, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

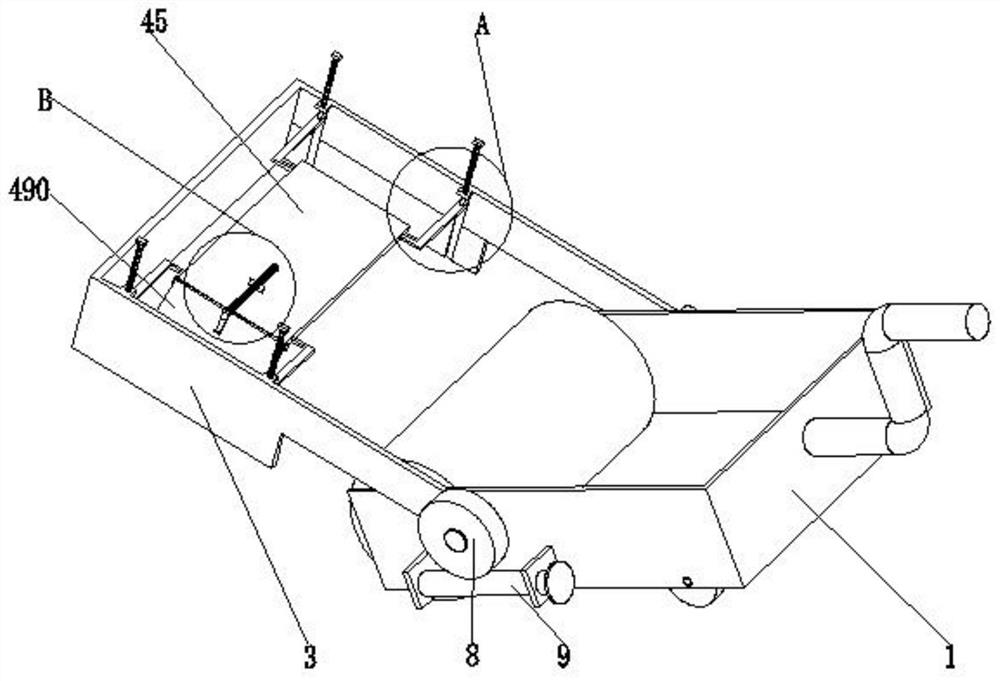

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

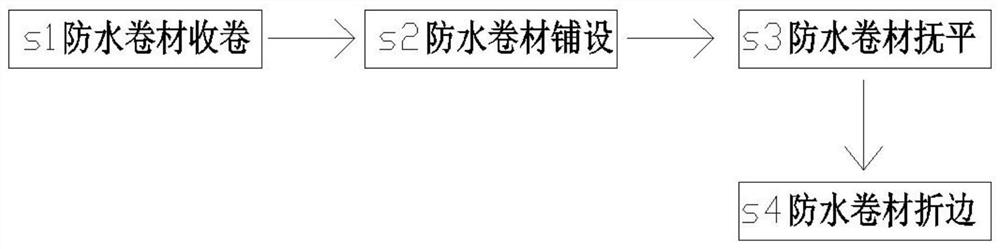

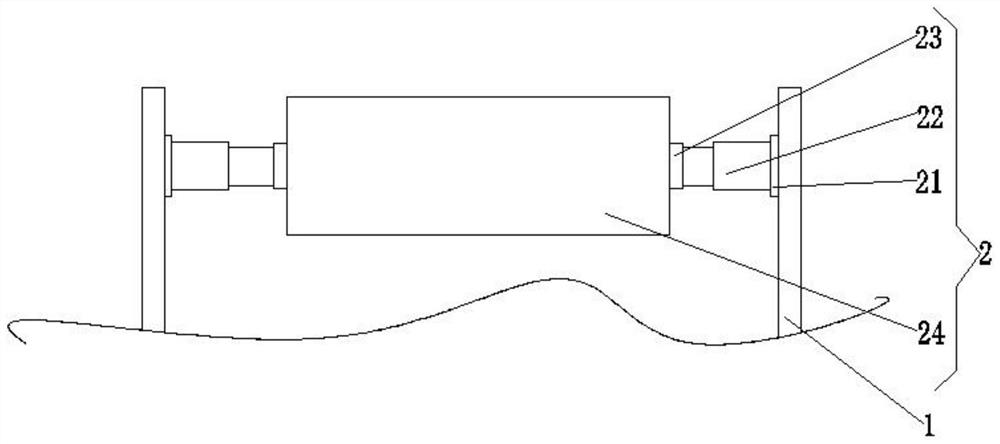

[0038] Such as Figure 1 to Figure 10 As shown, a water conservancy project waterproof coiled material construction method, which uses a paste and fold equipment, the paste and fold equipment includes a work frame 1, a rotating device 2, a turning frame 3, a lifting device 4 and a smoothing device 5, using the above-mentioned The construction method of pasting and folding equipment to the waterproof membrane of water conservancy projects includes the following steps:

[0039] S1. Winding of the waterproof membrane: when the bundled waterproof membrane is rolled outside the clamping cylinder 24, one end is pulled out so that one side of the waterproof membrane is pasted with the foundation;

[0040] S2. Laying of waterproof coiled material: by pulling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com