Hemmer and hemming method

A technology of crimping device and side plate, which is applied in the direction of decorative art and preserved paintings, can solve the problems of time-consuming and labor-intensive crimping effect, the crimping process is time-consuming and labor-intensive, and the operation is difficult, so as to improve the crimping efficiency, save labor, The effect of avoiding destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

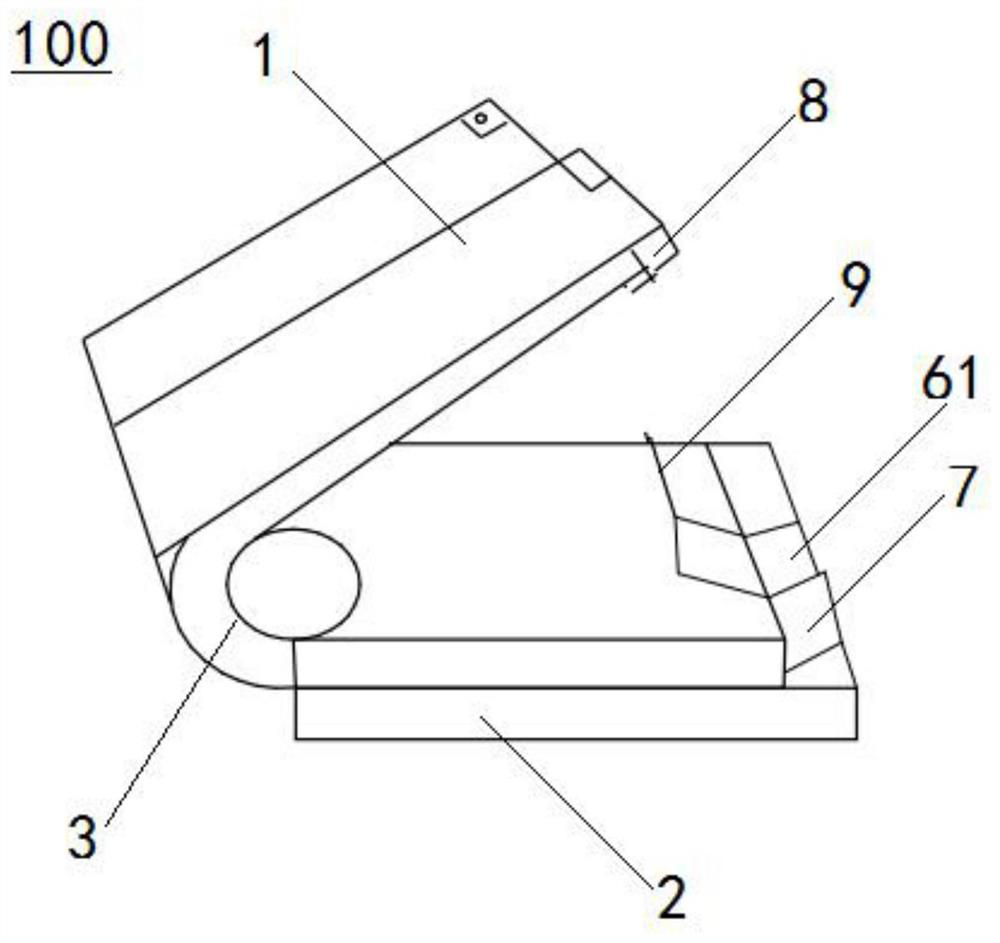

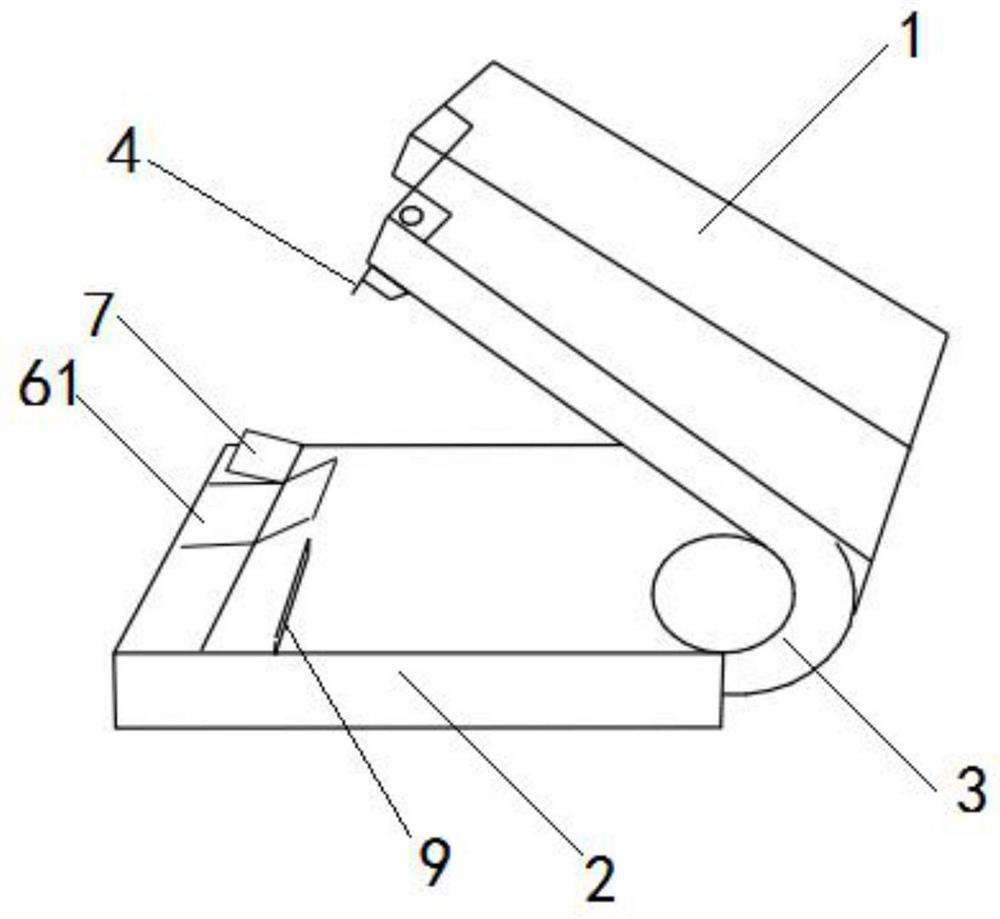

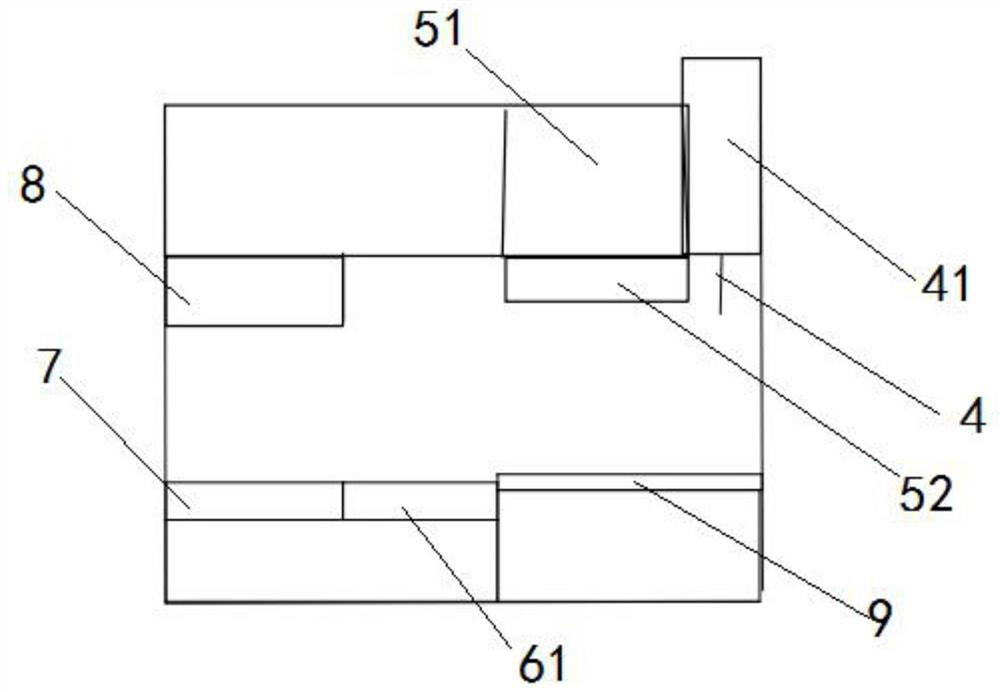

[0035] Such as Figure 1-Figure 4As shown, the present embodiment provides a crimping device 100, comprising a base 2, an upper plate 1, a scratching element, a brushing element and a turning element 6, one end of the base 2 is rotatably connected with one end of the upper plate 1, and the base 2 The distance between the other end of the upper plate 1 and the other end of the upper plate 1 can be adjusted, that is, the end of the upper plate 1 far away from the torsion spring 3 can move towards or away from the end of the base 2, the positional relationship and connection between the base 2 and the upper plate 1 The relationship is similar to that of a stapler, so that it is easy to operate with one hand and easy to use. The base 2 is used to place the silk edge of calligraphy and painting cultural relics, and the scratch element is fixed on the lower end surface of the upper plate 1. When the lower end surface of the upper plate 1 is used, The end surface of the upper plate 1...

Embodiment 2

[0048] This embodiment provides a crimping method based on the crimping device 100 in the first embodiment, including the following steps:

[0049] S1: Place the silk edge of the calligraphy and painting cultural relics between the upper plate 1 and the base 2, and place it on the upper end surface of the base 2, so that the outer edge of the silk edge touches the limit plate 9, and in the initial state, the edge curler 100 is close to One end in the length direction of the silk edge can realize curling of the entire silk edge during the process of the crimping device 100 moving from one end of the silk edge to the other side, so as to improve the curling efficiency;

[0050] S2: Turn on the power switch of the heating ironer 8, press the upper plate 1, and make the scratch needle 4 touch the upper end surface of the silk edge, so as to operate on the upper end surface of the silk edge, and move to the other side near the length direction of the silk edge Move the crimping dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com