Separate Hopkinson rod tension/compression-torsion dynamic compound loading device and operation method

A composite loading and loading device technology, applied in measuring devices, using stable tension/compression to test material strength, analyzing materials, etc., can solve the inability to achieve tension/compression-torsion composite dynamic dynamic load testing, longitudinal wave asynchrony and other problems, to achieve the effect of small footprint, solving asynchrony, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described below in conjunction with specific embodiments.

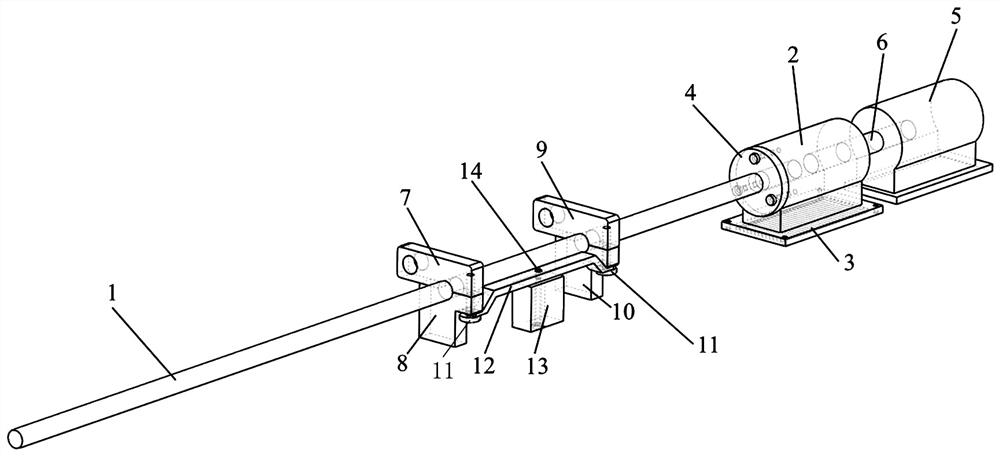

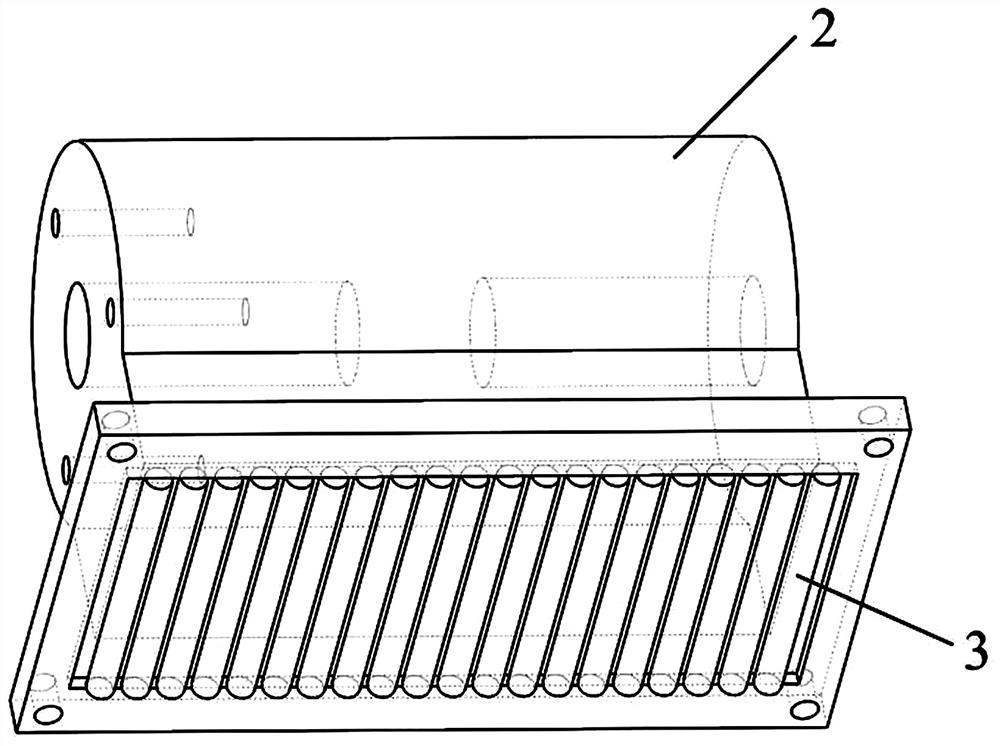

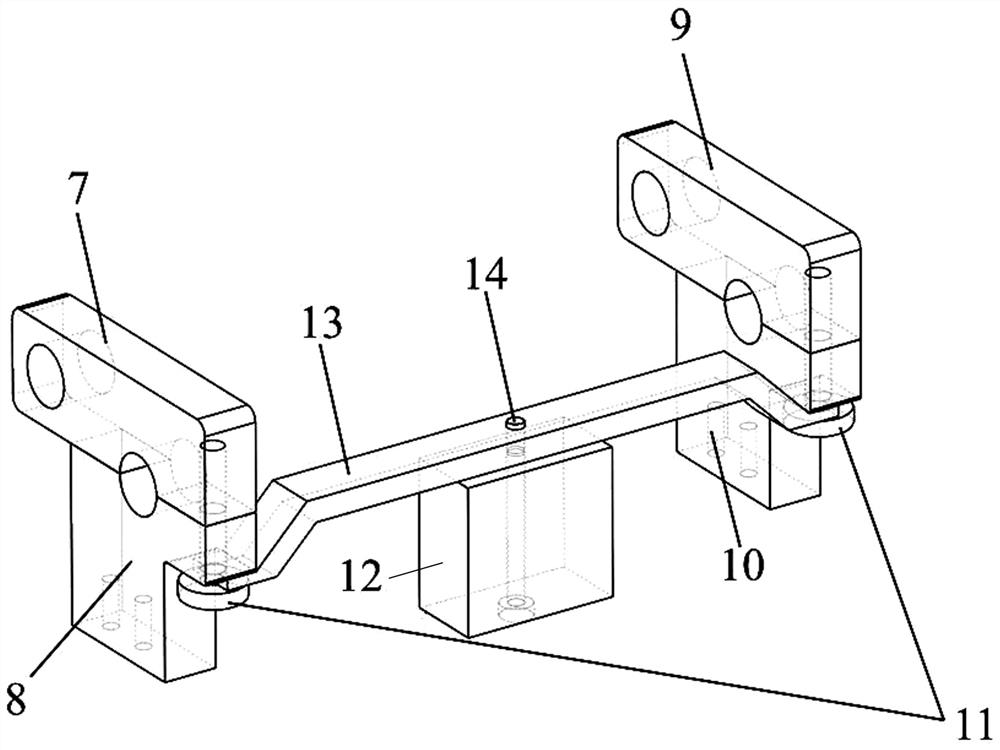

[0033] A separate Hopkinson rod pull / pressure-torsion dynamic composite loading device, such as Figure 1 Shown: including incident rod 1, torsional loading device, tensile / compression loading device, clamping fastening mechanism and synchronous release mechanism; The tensile / compression loading apparatus comprises a horizontal energy storage device 5, a lead screw transmission 6 and an internal worm gear transmission, the torsional loading apparatus comprising a torsional energy storage device 2, a horizontal slider 3 and a torsional fixing flange 4, such as Figure 2shown; The torsional energy storage device 2 is fixed to the horizontal slider 3, the horizontal slider 3 is provided with a fixed threaded hole in the four corners of the bottom surface, the torsional fixing flange 4 is provided at the front end of the torsional energy storage device 2, the torsional energy storage de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com