An automatic led lamp head assembly material conveying line body

A technology of LED lamp head and conveyor line, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of inability to achieve modular design, high cost of material lines, large space occupation, etc., to avoid asynchrony , The effect of good processing performance and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

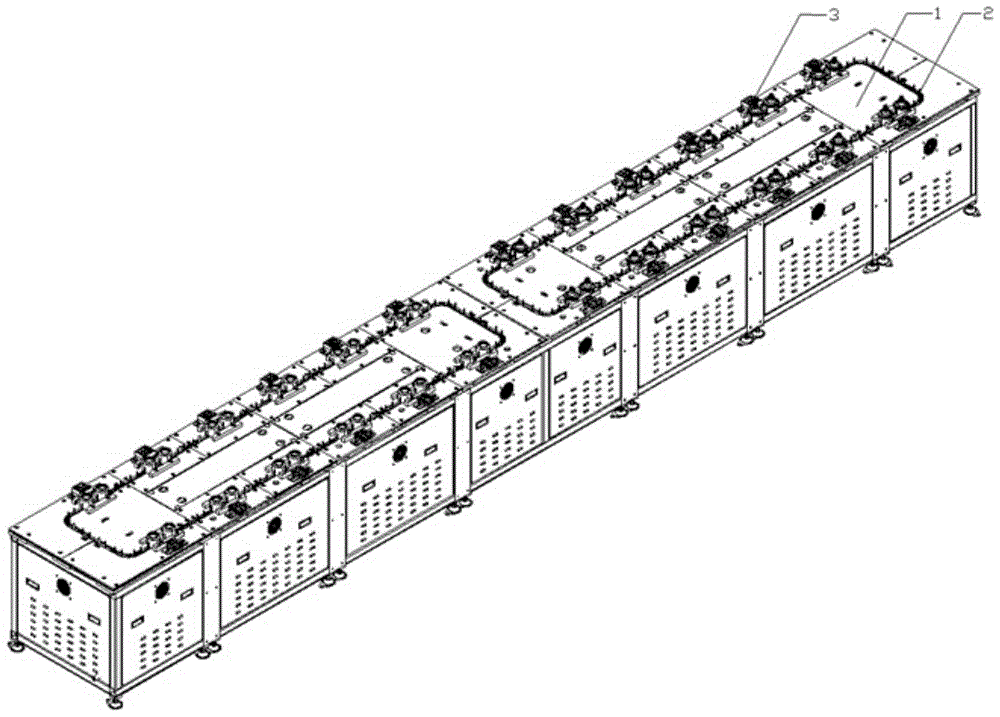

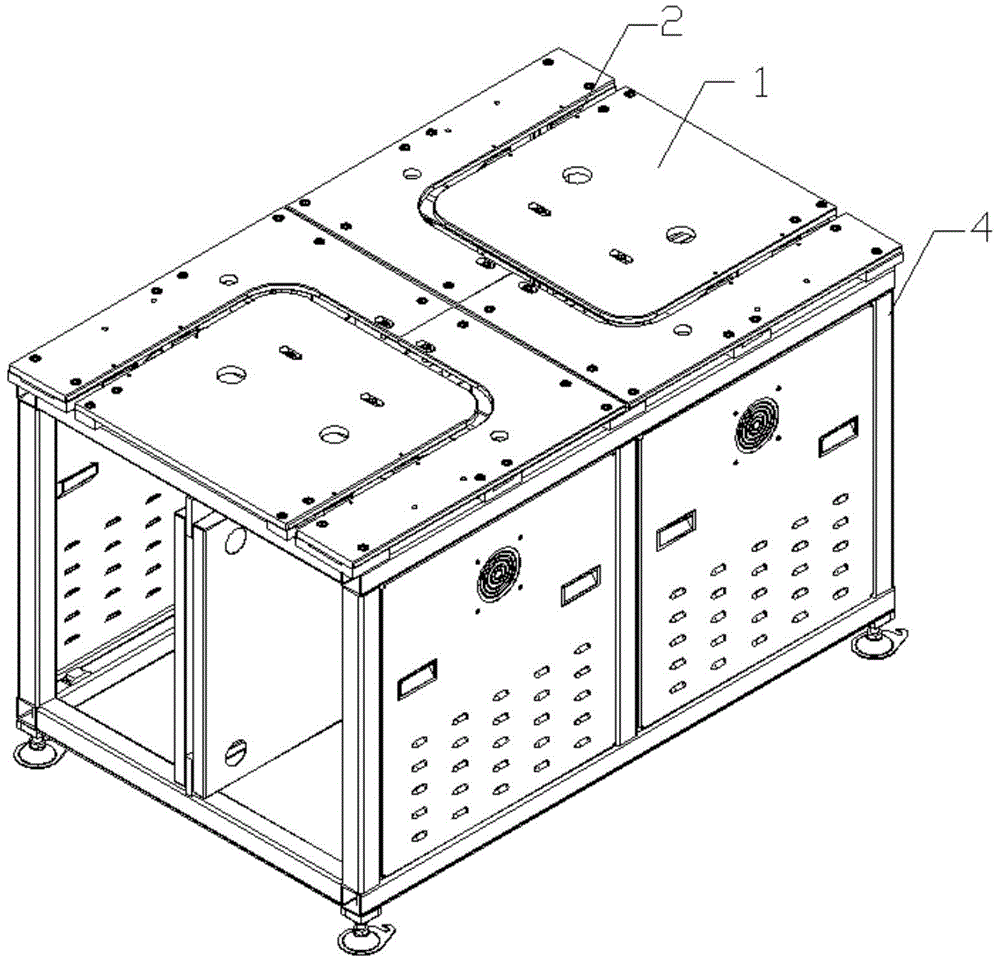

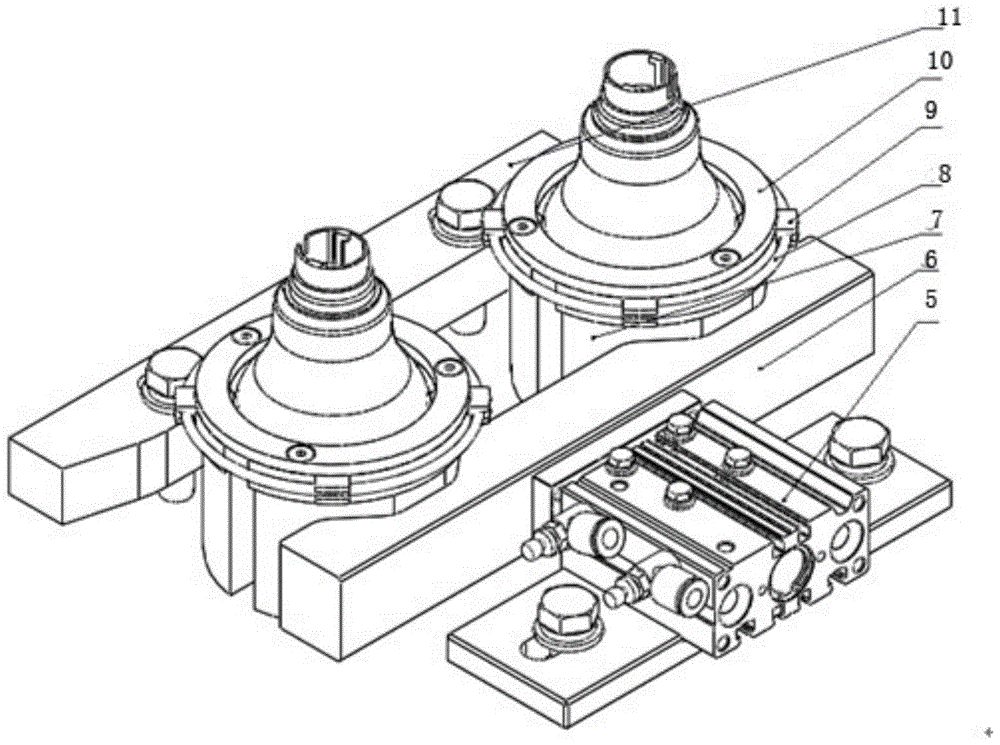

[0035] Such as figure 1 As shown, an automated LED lamp head assembly material conveying line body includes a frame 4, a lamp head positioning tooling module 3, a chain 2, and a line body module 1, such as figure 2 As shown, the line body module 1 includes a front line device and a rear line device, the front line device is equipped with a light source of a lamp, the rear line device is equipped with a lamp head of a lamp, and the front and rear lines Except for the tooling, the structure is basically the same. Such as image 3 As shown, the lamp head positioning tooling module 3 includes a cylinder 5 and a V-shaped block 6, the V-shaped block 6 is installed on the cylinder 5, and the V-shaped block 6 is positioned with a tooling body 7 through a positioning block 11 , the clamping blocks 9 are evenly distributed in the chute of the tooling body 7, and the clamping blocks 9 clamp the lamps through the spring force of the oil seal spring 8, and the tooling body 7 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com