Shift-by-wire shift actuator

A shift-by-wire, actuator technology, applied in transmission control, elements with teeth, belts/chains/gears, etc., can solve the increased complexity and cost of vehicle shift-by-wire assembly manufacturing and operation and other issues to achieve the effect of reducing complexity, avoiding asynchrony, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

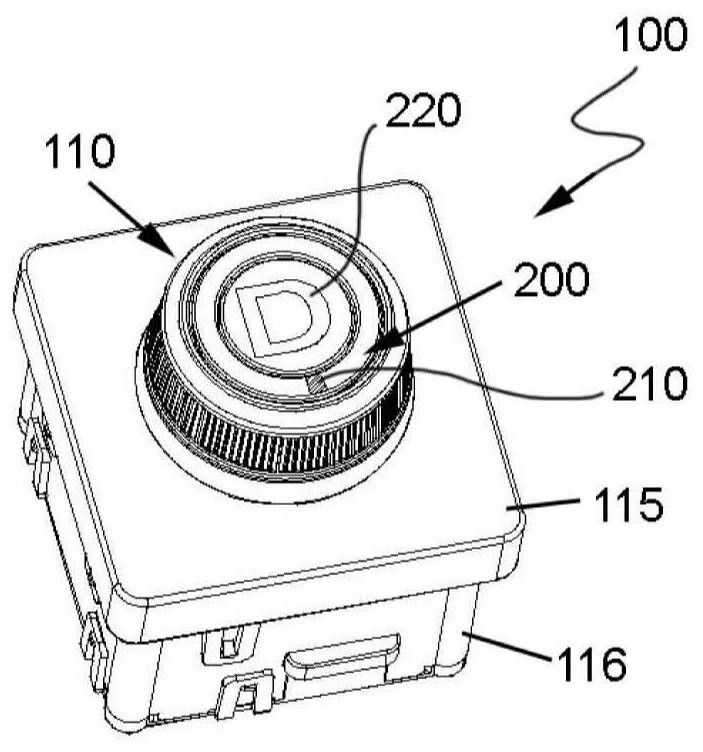

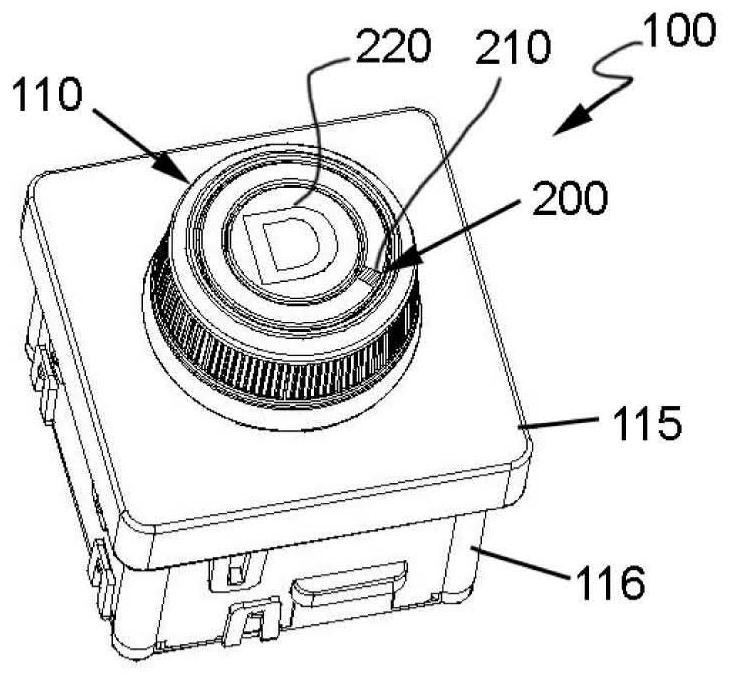

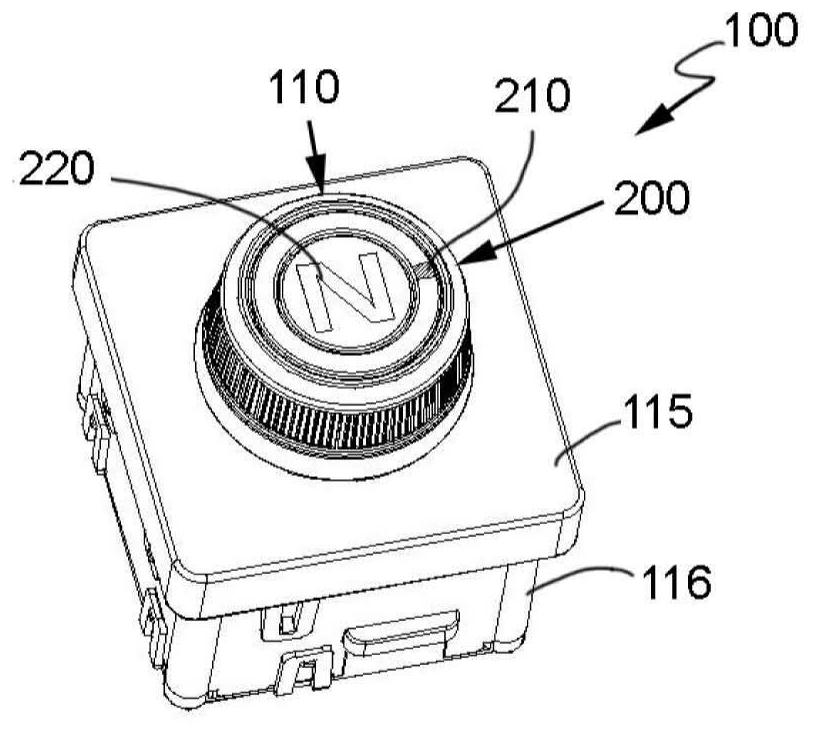

[0032] By way of example, a shift-by-wire shift actuator for controlling a vehicle transmission, generally indicated by the reference numeral 100 , is shown in the drawings. The actuator 100 may be part of a shift-by-wire transmission device having an automatic park function for automatically driving the vehicle transmission into park when certain conditions are met, as will be described herein below. car shift position.

[0033] Specifically, Figure 1 to Figure 9 The shift-by-wire shift actuator 100 in the example shown in is part of a rotary multi-dial shifter and includes a selector knob 110 , a bezel 115 and a housing 116 . The selection knob 110 is rotatably mounted on a bezel 115 in a housing 116 . Thus, the selector knob 110 is rotatable to select one of a plurality of shift positions, such as Park P, Reverse R, Neutral N, and Drive D, to control the vehicle transmission.

[0034] According to the example shown, the shift-by-wire shift actuator 100 includes a display...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com