Test tool for notebook computer flexible circuit board production

A flexible circuit board, notebook computer technology, applied in electronic circuit testing, printed circuit testing, measuring devices, etc., can solve problems such as poor versatility and single function, and achieve the effect of simple structure, wide range of scenes and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

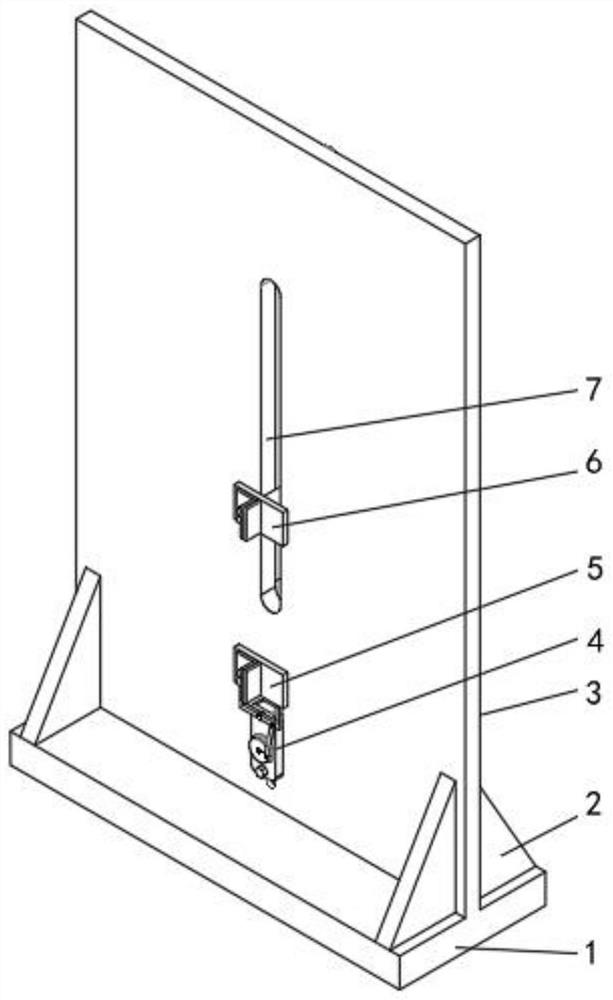

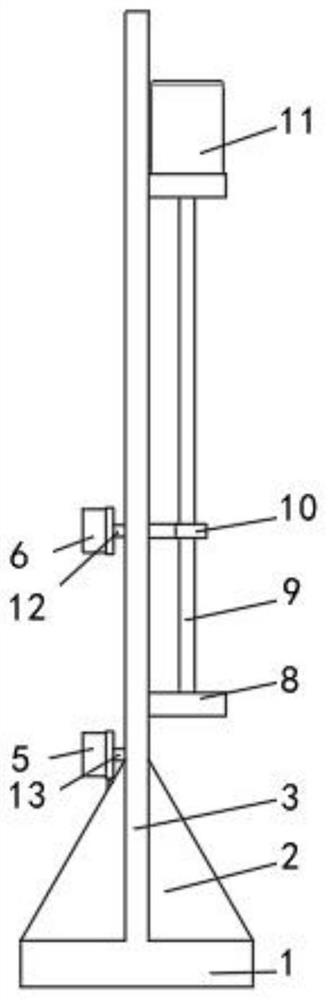

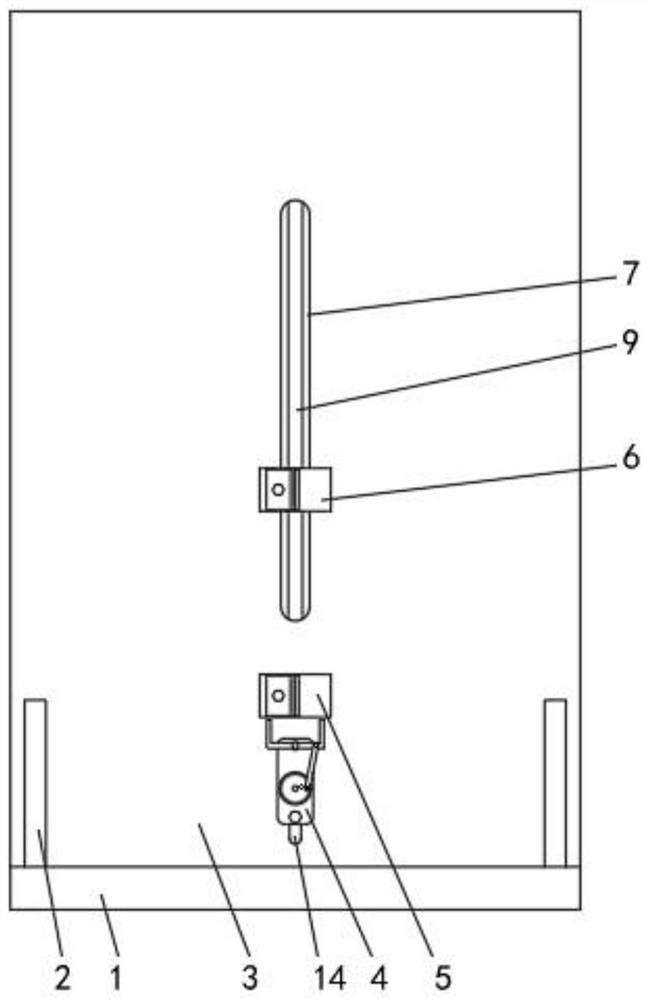

[0034] Such as Figure 1-6 As shown, the embodiment of the present invention provides a test tool for the production of notebook computer flexible circuit boards, including a base 1, the upper end of the base plate 1 is fixedly connected with a riser 3, and the upper side wall of the riser 3 is provided with a second A chute 7, the first chute 7 is provided with a second clamping device 6, the second clamping device 6 can slide on the first chute 7, the front of the riser 3 and on the side of the first chute 7 There is a first clamping device 5 directly below, and by controlling the position of the second clamping device 6 in the first chute 7, the distance between the first clamping device 5 and the second clamping device 6 is controlled. The back side of a clamping device 5 is rotatably connected with a second rotating shaft 13, and the other end of the second rotating shaft 13 is fixedly connected with the side wall of the riser 3. The first clamping device 5 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com