Variable frequency motor fault monitoring system

A variable frequency motor and fault monitoring technology, which is applied in the direction of motor generator testing, measuring electricity, measuring devices, etc., can solve the problems of false alarms of variable frequency motor faults, and achieve the effects of reducing false positives, improving accuracy, and reasonable alarm mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

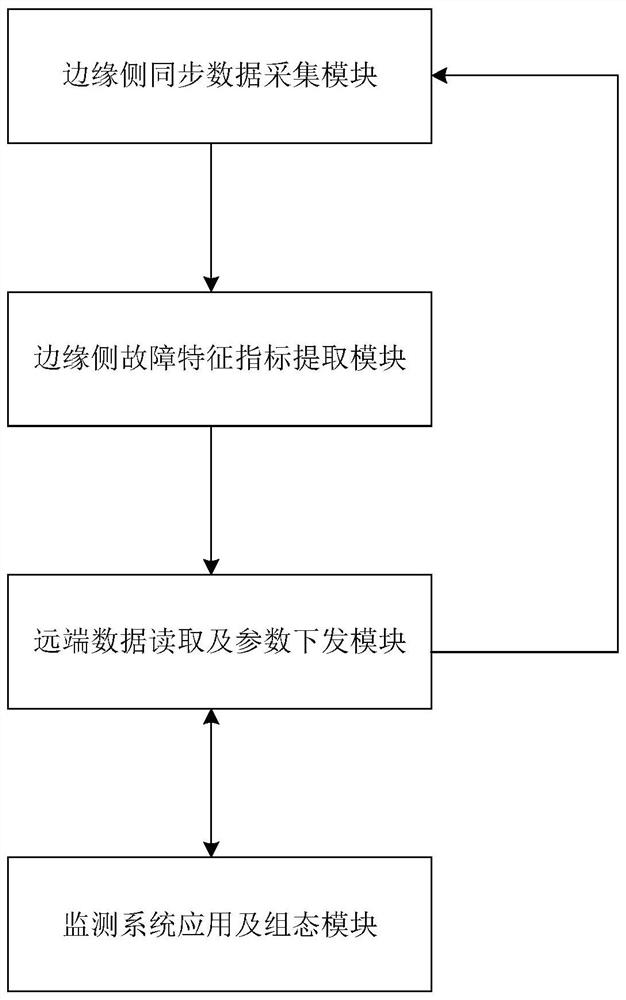

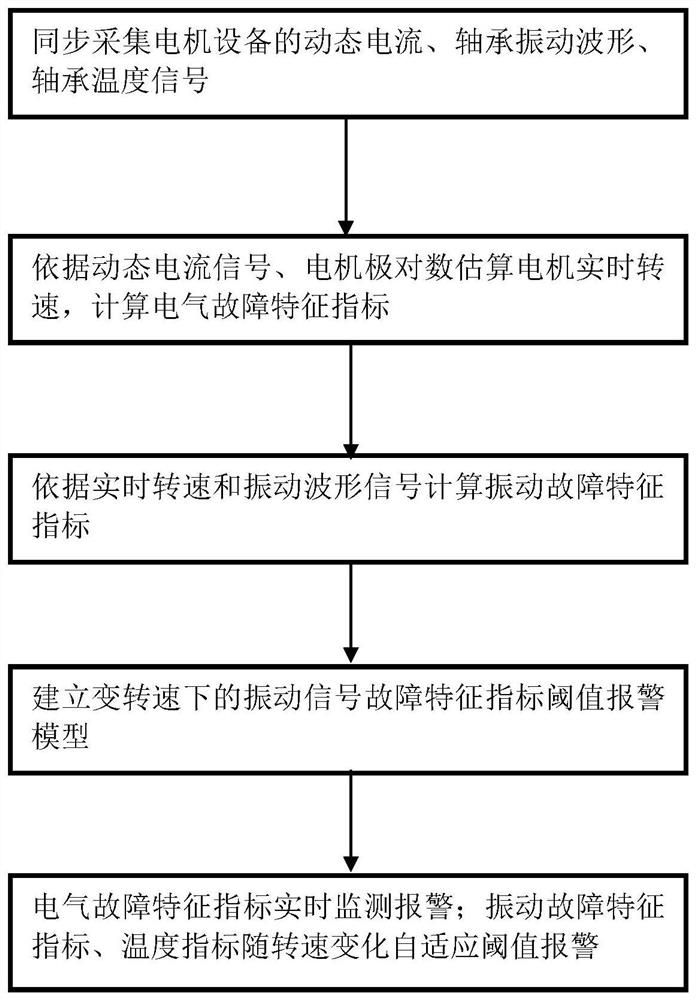

[0022] A kind of frequency conversion motor fault monitoring system of the present invention, the composition of this system is as follows figure 1 As shown, it includes edge-side data acquisition module, edge-side feature extraction module, remote data reading and parameter delivery module and monitoring system. Among them, the edge-side data acquisition module is used for synchronous acquisition of the current signal, vibration signal and temperature signal of the variable frequency motor.

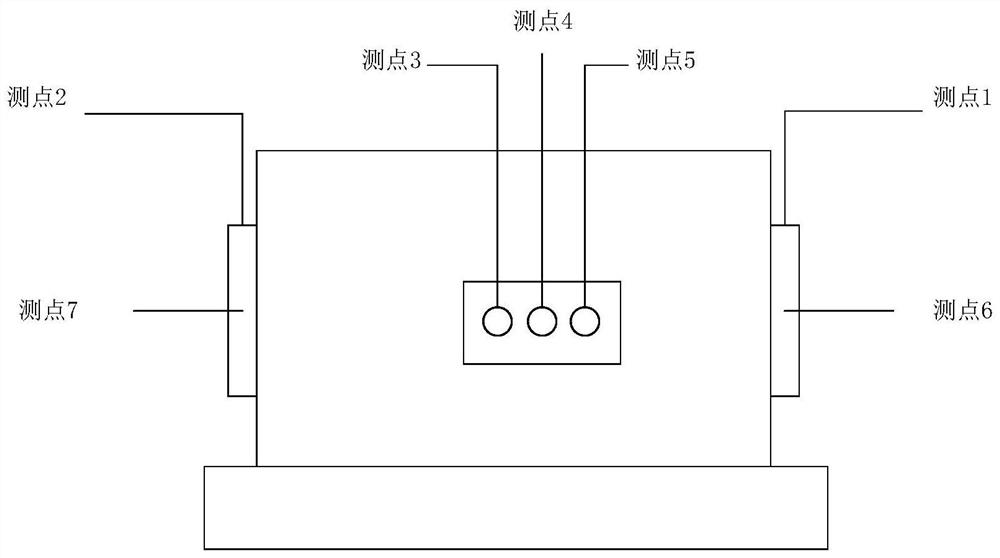

[0023] In this embodiment, the hardware configuration of an edge-side data acquisition module mainly includes a vibration sensor, a current sensor, a temperature sensor, and an edge intelligent collector. The collector synchronously collects vibration signals, temperature signals, and three-phase Dynamic current signal.

[0024] The specific location...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap