Detachable cast-in-place concrete pavement and pouring method

A technology of concrete pavement and concrete, which is applied to cohesive pavement paved on site, roads, roads and other directions, which can solve the problems of long construction period and achieve the effect of saving time and effort in dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-4 The application is described in further detail.

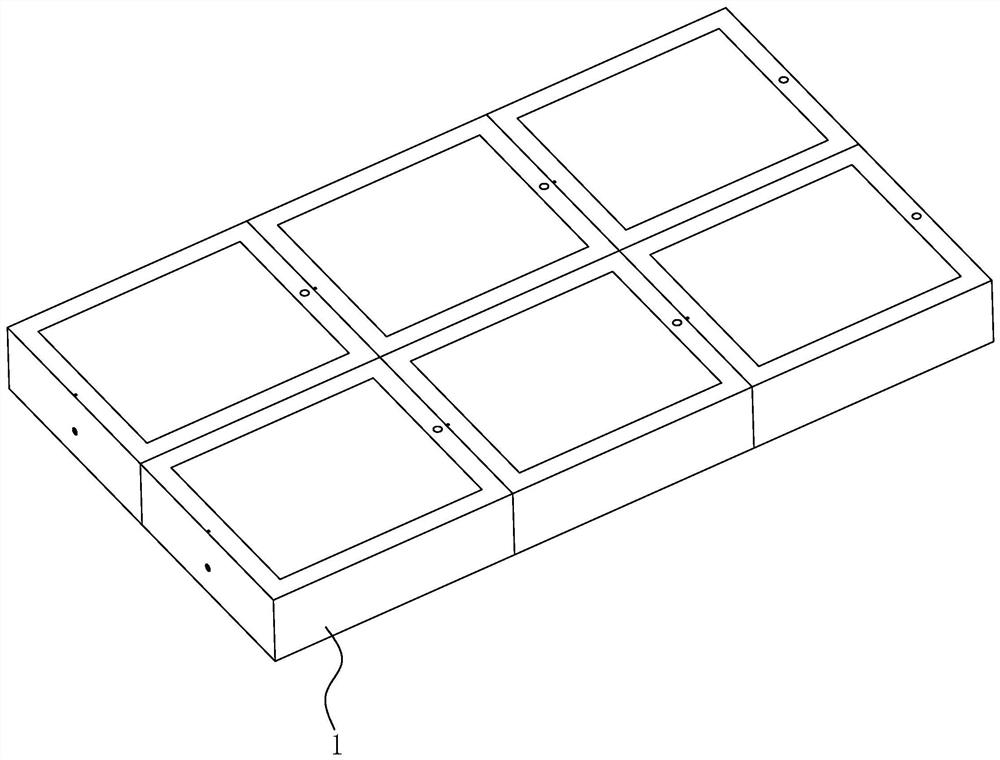

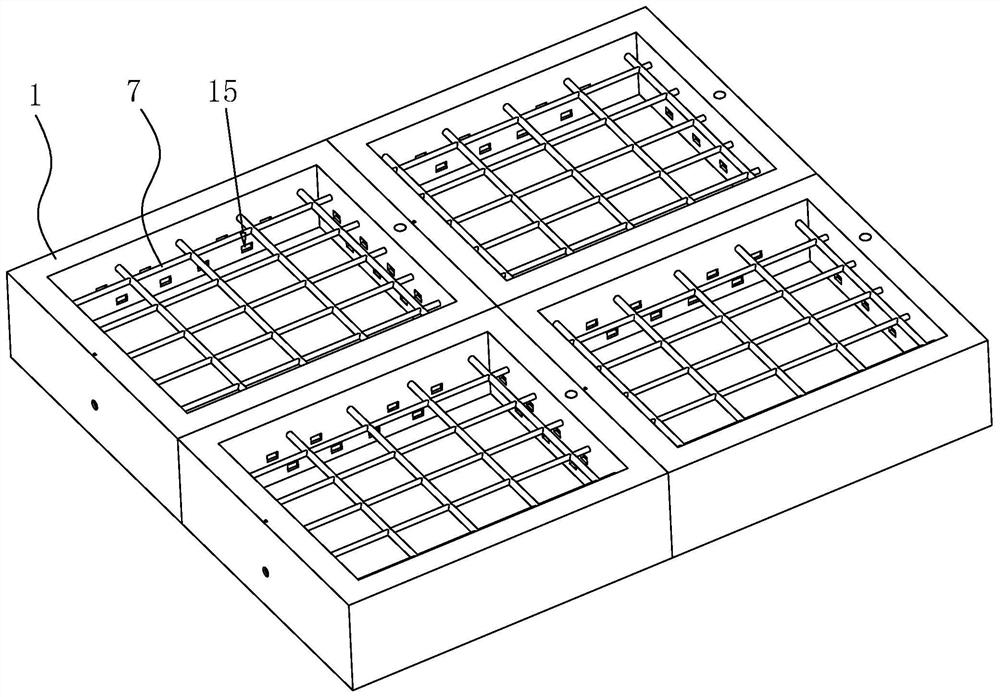

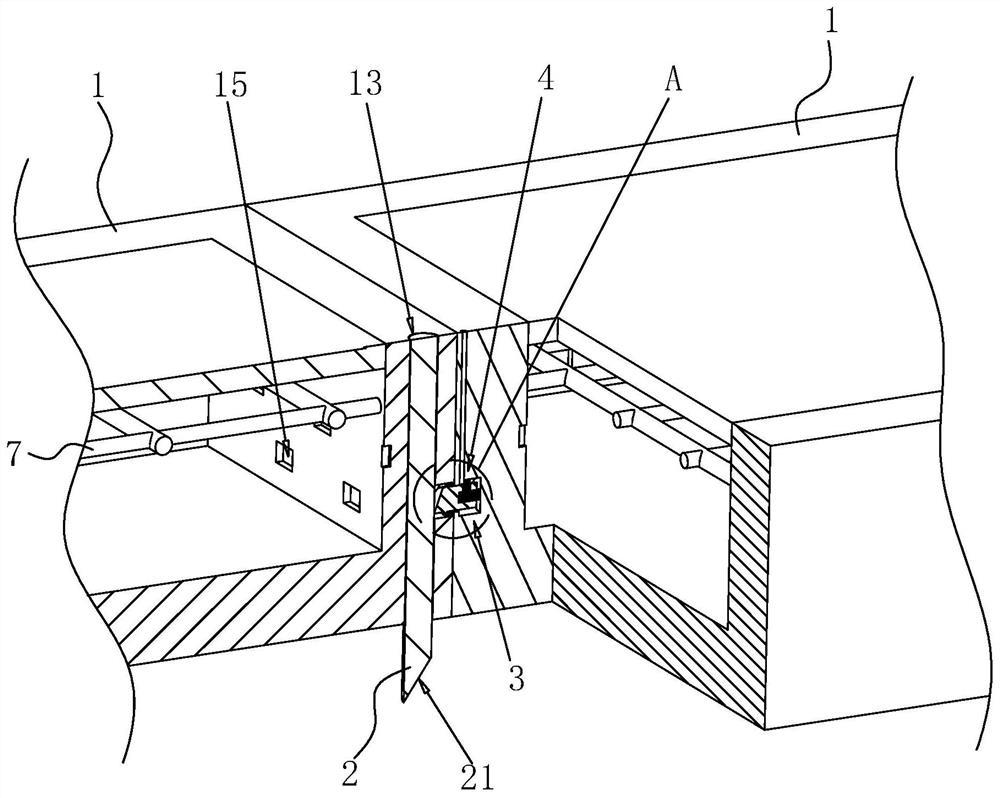

[0037] The embodiment of the application discloses a detachable cast-in-place concrete pavement. refer to figure 1 , figure 2 , the detachable cast-in-place concrete pavement includes a plurality of square boxes 1, the interior of the square box 1 is hollow and the upper end is opened, and the square box 1 is used for pouring concrete; the interior of the square box 1 is welded with multiple reinforcement bars 7, Reinforcing bars 7 are horizontally welded in the square box 1, and the setting of reinforcing bars 7 can improve the structural stability of the entire square box 1 after concrete pouring; and the inner side wall of the square box 1 is provided with a plurality of concrete introduction holes 15, and the concrete is introduced The hole 15 can be used for concrete to flow in, so that the square box 1 and the concrete can be connected more stably after the concrete solidif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com