Automatic seasoning mashing device

An automatic and seasoning technology, which is applied in household appliances, household machinery for filtering food, and other applications. It can solve the problems of inconvenient discharge from mashing tanks, etc., and achieve the effect of improving discharge efficiency, improving raw material mashing efficiency, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

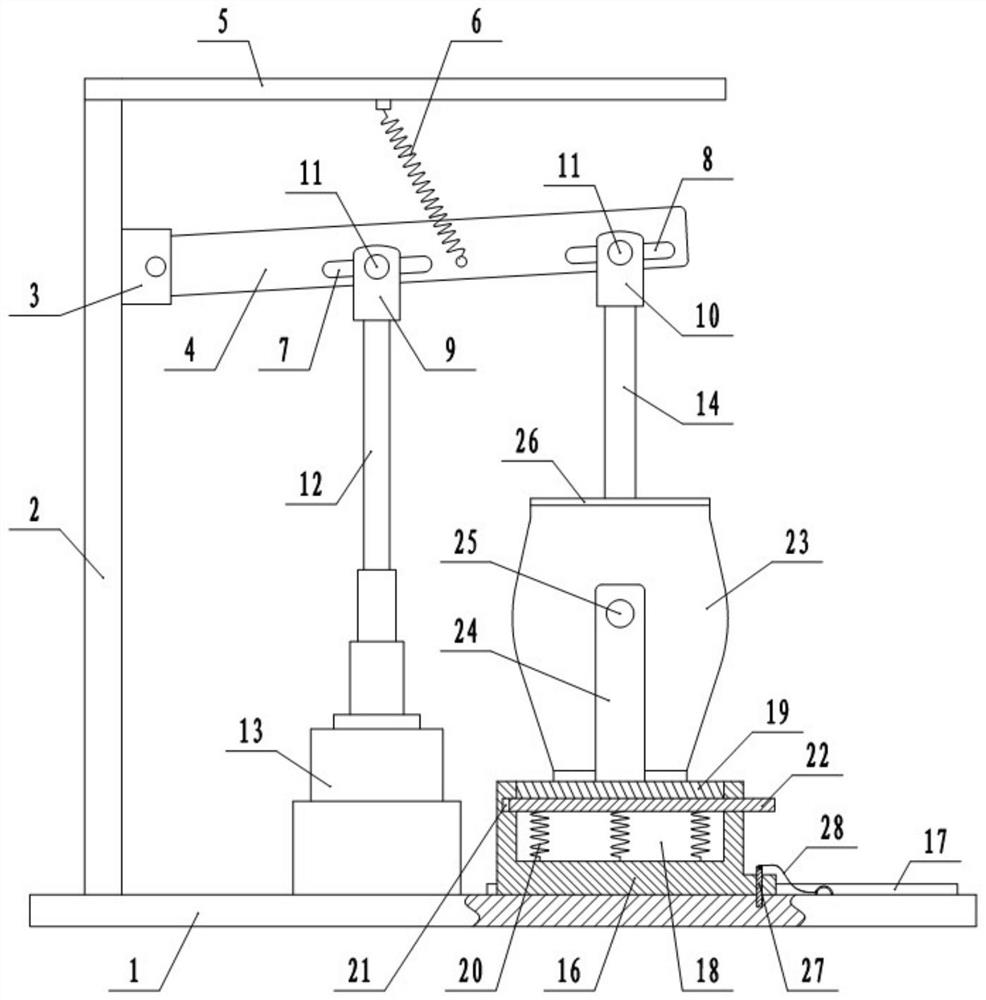

[0033] This embodiment is basically as figure 1 Shown: the seasoning automatic smashing device, including a base 1, a bracket 2 is welded on the base 1, the top of the bracket 2 is fixedly connected with a fixed block 3 by bolts, and the fixed block 3 is hinged with a swing plate 4. In this embodiment, the swing plate The left end of 4 is hinged on the fixed block 3 by pin shaft. A horizontal plate 5 is welded on the top of the support 2, a return spring 6 is welded on the transverse plate 5, and the bottom end of the return spring 6 is welded to the swing plate 4.

[0034] The middle part of the swing plate 4 is provided with a waist hole 17 arranged along the length direction of the swing plate 4, and the right end of the swing plate 4 is provided with a waist hole 2 8 arranged along the length direction of the swing plate 4, and the waist hole 17 is slidingly connected. There is a mounting block 19, and a mounting block 10 is slidably connected in the waist hole 28. Specif...

Embodiment 2

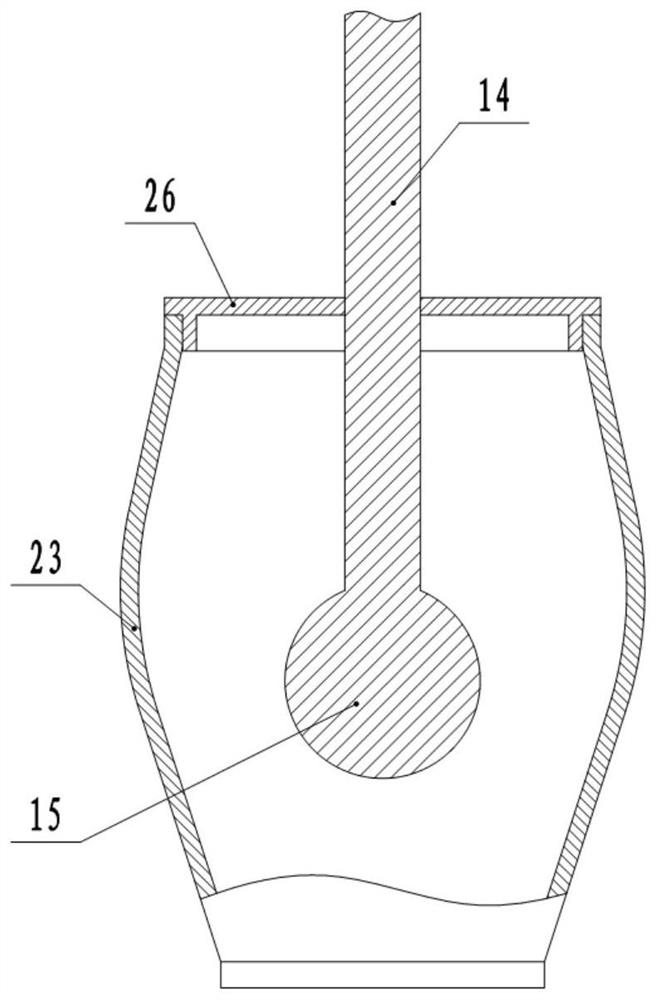

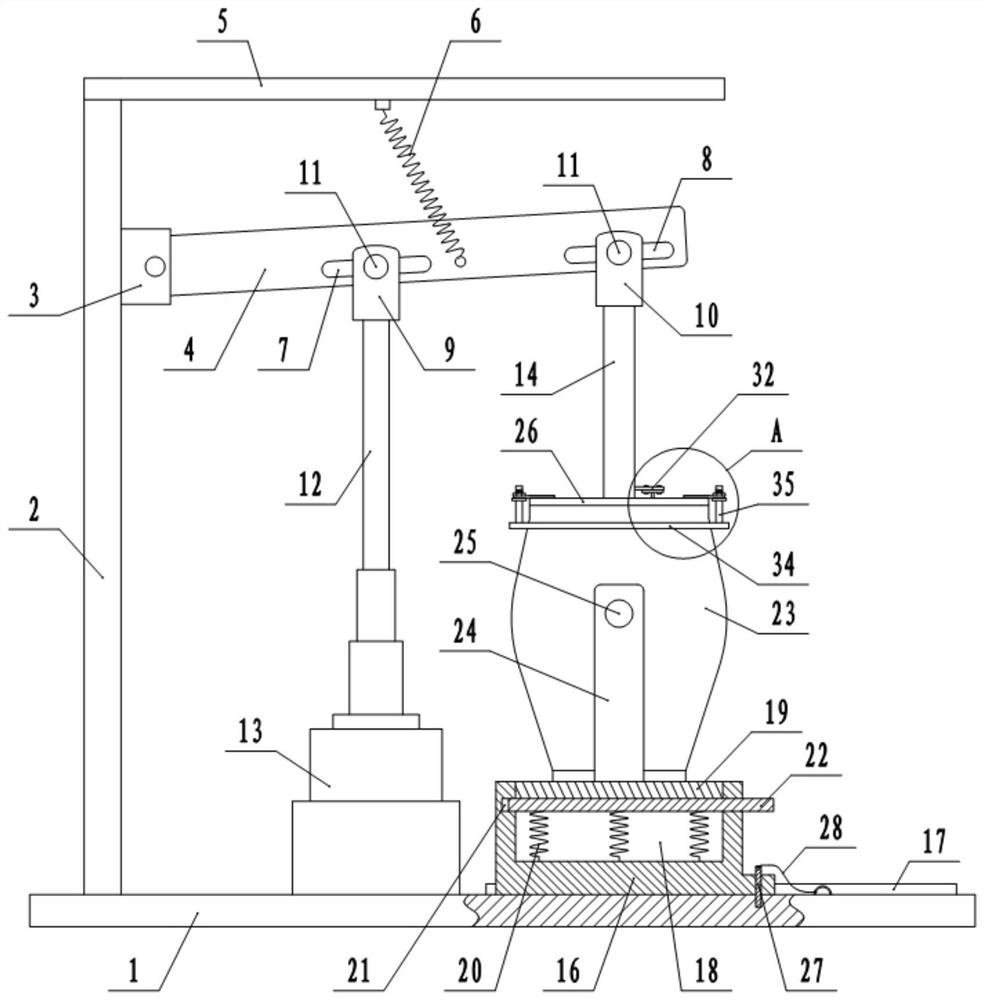

[0043] The difference between this embodiment and Embodiment 1 is that: image 3 , Figure 4 with Figure 5 As shown, the stamping hammer 15 is provided with some vertical passages 29, and in the present embodiment, the number of passages 29 is five ( Figure 4 Only three passages 29 can be seen in the middle passage 29, and the other two passages 29 are located at the front side and the rear side of the middle passage 29), the inside of the hammer rod 14 is provided with a cavity 30, the cavity 30 is an inverted L shape, and the cavity 30 There are five pushing rods 31 corresponding to the passages 29, the bottom ends of the pushing rods 31 extend into the corresponding passages 29, and the tops of the pushing rods 31 are jointly welded with a transverse piece 32, and the transverse piece 32 extends out of the cavity 30 . A T-shaped connecting piece 33 is welded on the cover plate 26 , and the connecting piece 33 and the transverse piece 32 are detachably connected by bolt...

Embodiment 3

[0048] The difference between the present embodiment and the second embodiment is that in the present embodiment, the driving member 13 is a push rod motor, and since the push rod motor can drive the drive rod 12 to move up and down, it is not necessary to design the horizontal plate 5 and the return spring 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com