Automobile rear corner window decoration plate and automobile

A technology for rear corner and window trim, applied in the field of body parts, can solve the problems of many installation points of rear corner window trim and body sheet metal, water leakage at installation points, installation difficulties, etc., so as to avoid water leakage and abnormal noise problems, large The effect of innovation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

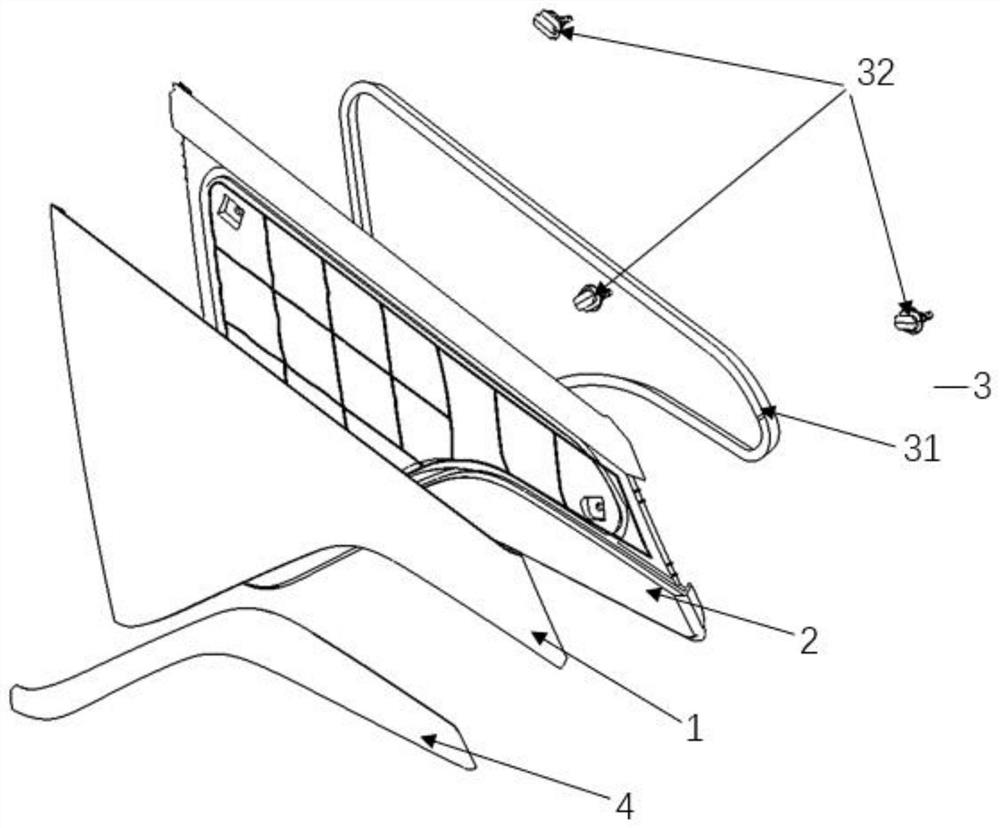

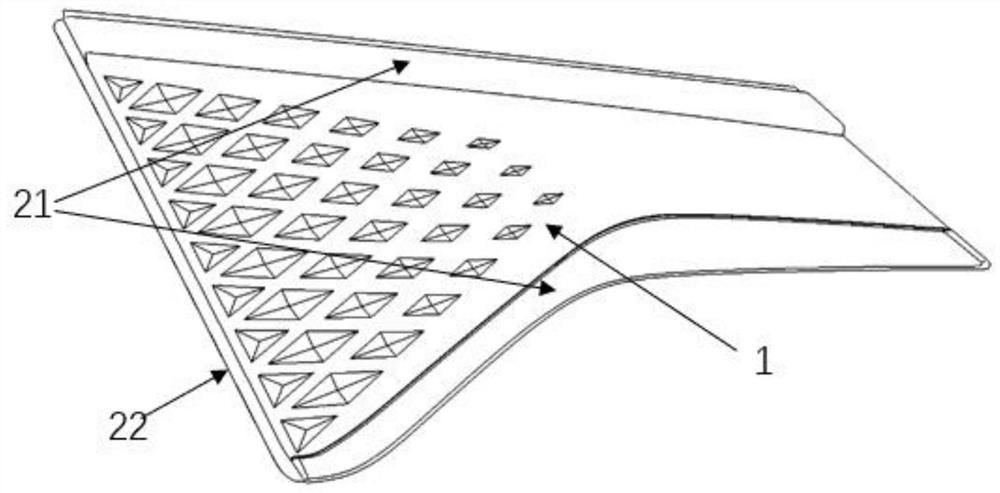

[0028] Such as Figure 1-3 As shown, the embodiment of the present invention provides a kind of automotive rear corner window trim, comprising a main body panel 1, a back panel 2 and a fixing structure 3; the main body panel 1 is arranged above the back panel 2, and the back panel 2 Both sides are provided with a raised decorative transition area 21, and the two side edges of the main body panel 1 are connected with the decorative transition area 21;

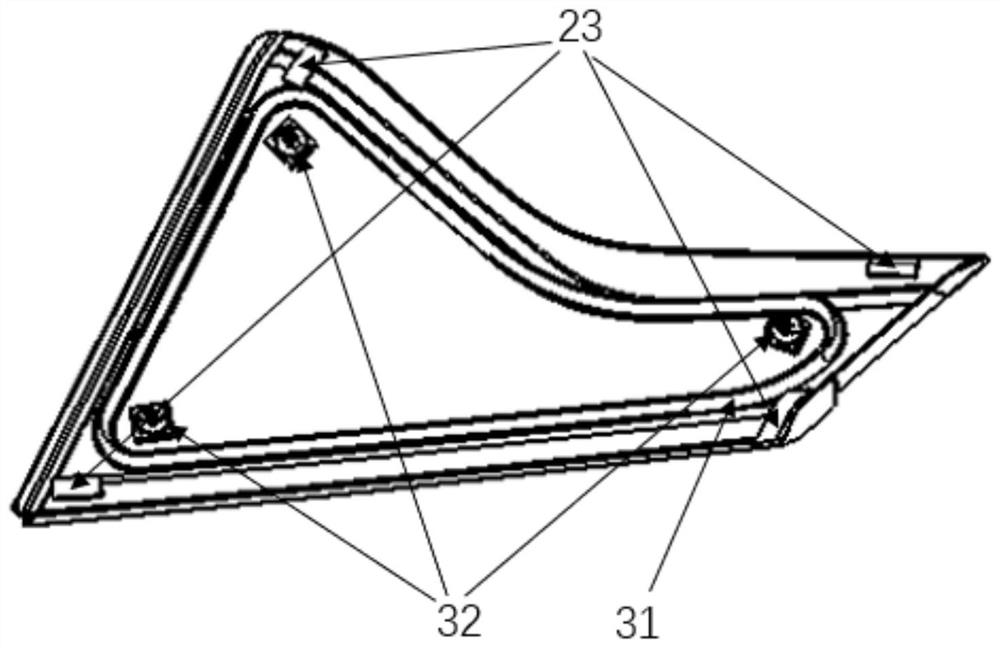

[0029] The fixed structure 3 is arranged on the inner side of the back plate 2, and the fixed structure 3 includes a sealing ring 31 and a plurality of buckles 32, and the back plate 2 is connected to the body sheet metal 5 (accompanying drawing) through the buckles 32 (not shown in ), the sealing ring 31 is arranged on the outer ring of a plurality of snap-fit buckles 32 , and the sealing ring 31 is used to bond and seal the back panel 2 and the vehicle body sheet metal 5 . Specifically, in this embodiment, the sealing ring ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap