Automatic painting device for inner wall of round pit

A shaded well and automatic technology, which is applied to the field of automatic painting devices for the inner wall of a round shaded well, can solve the problems of low application efficiency and difficult operation of concrete application, and achieves the effects of high application efficiency, novel idea and labor reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

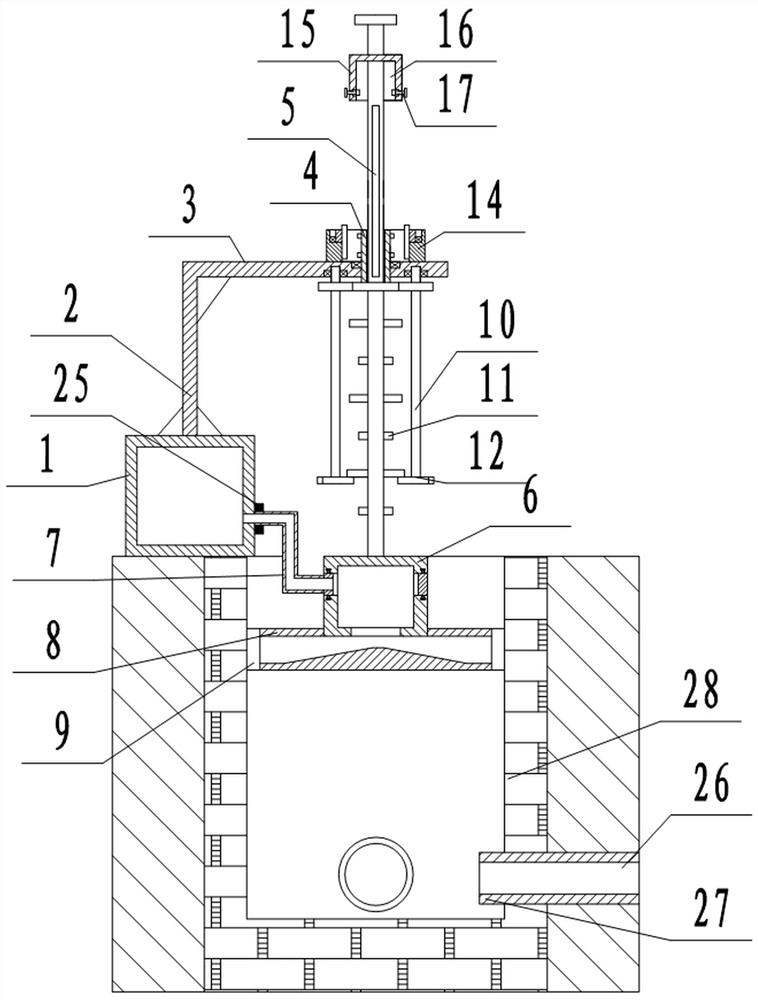

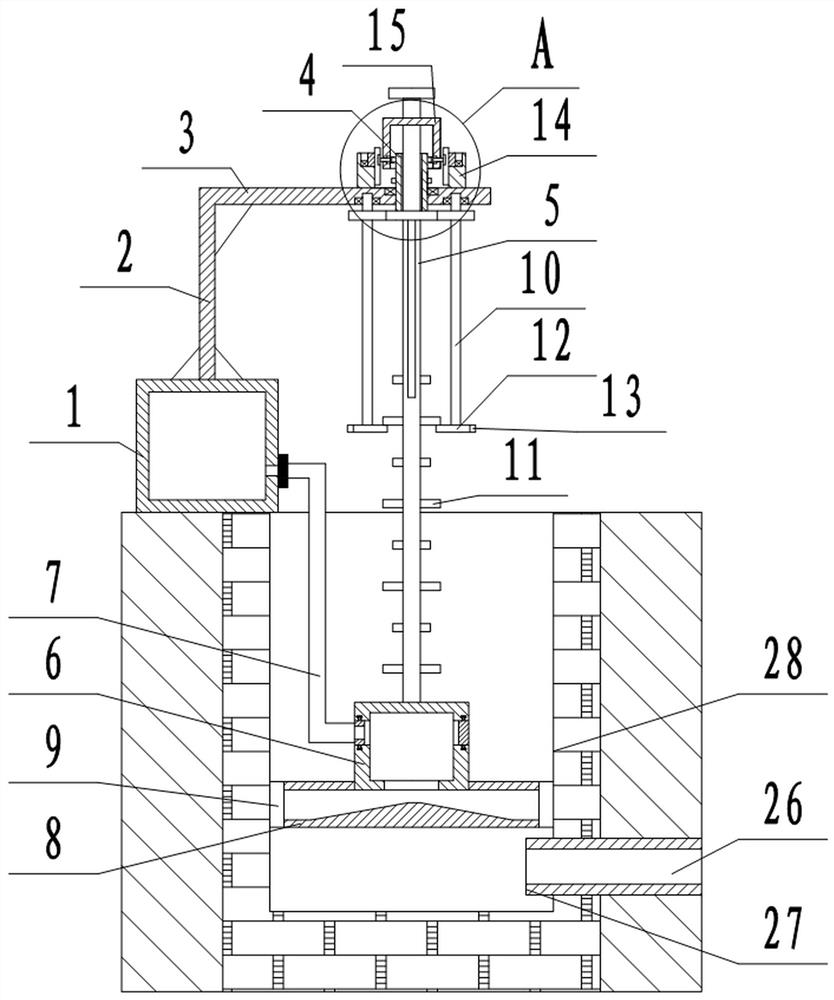

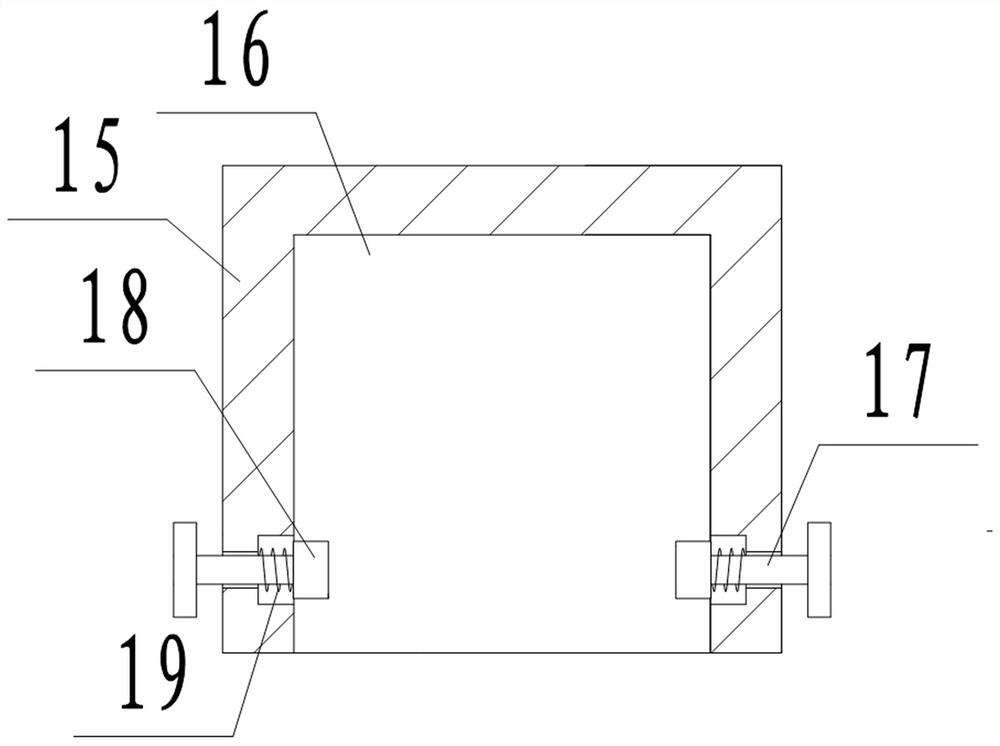

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Depend on Figure 1 to Figure 8 Given, the present invention comprises a round shade well, the inner wall 28 of the round shade well has a drain 26, the drain 26 is located at the bottom of the round shade well 28, and has a protruding end towards the inner wall 28 of the round shade well 27. It is characterized in that the automatic painting device includes a concrete application device, a storage tank 1, and a drive application mechanism. The drive application mechanism includes a vertical movement unit, a circular movement unit, and a reciprocating rotation unit. The concrete application device It is rotatably connected with the storage tank 1. When the concrete smearing device is located above the protruding end 27, the circular motion unit drives the concrete smearing device to make a circular motion along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com