Glass curtain wall stress detection method

A glass curtain wall, stress detection technology, applied in the direction of measuring force, measuring device, and force measurement by measuring the change of optical properties of materials when they are stressed, which can solve the problem of poor contrast of stress fringe images during the day, and detection can only be carried out at night. , the stress extraction process is complex and other problems, to reduce interference, improve accuracy and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make those skilled in the art understand the core idea of the present invention more clearly, it will be described in detail below with reference to the accompanying drawings.

[0042] A glass curtain wall stress detection method, the specific process is as follows Figure 4 shown.

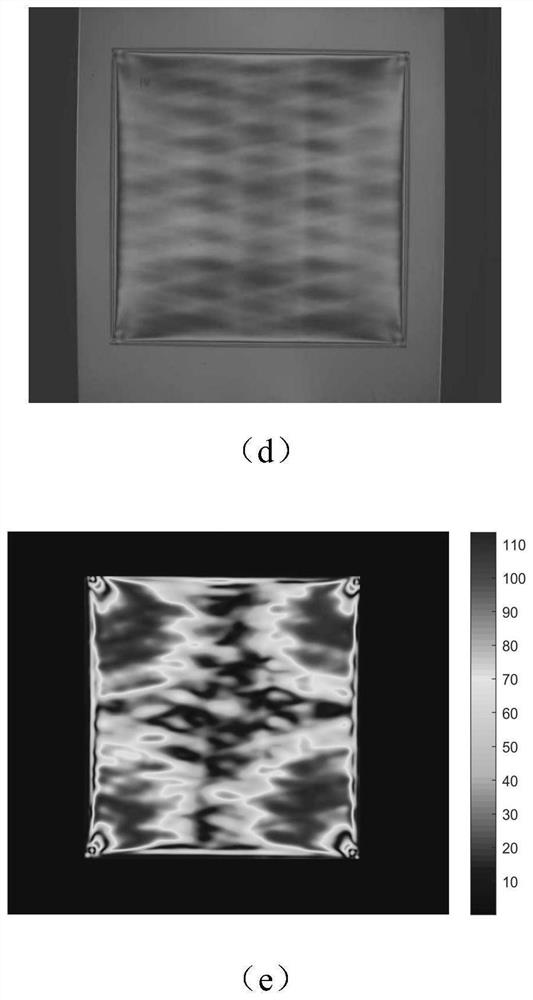

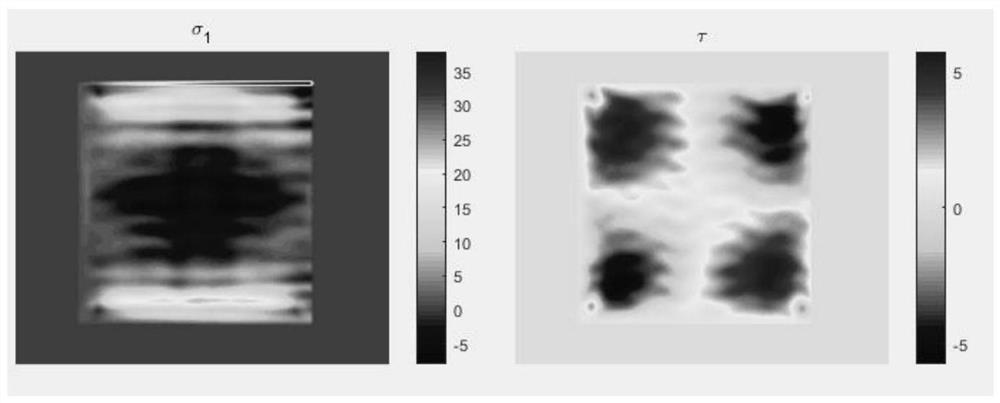

[0043] It mainly includes: using the principle of reflection photoelasticity for preliminary qualitative detection to determine the stress concentration area of the glass curtain wall, and then using the principle of transmission photoelasticity to perform accurate quantitative stress detection on the stress concentration area.

[0044] Specifically, the following steps are included:

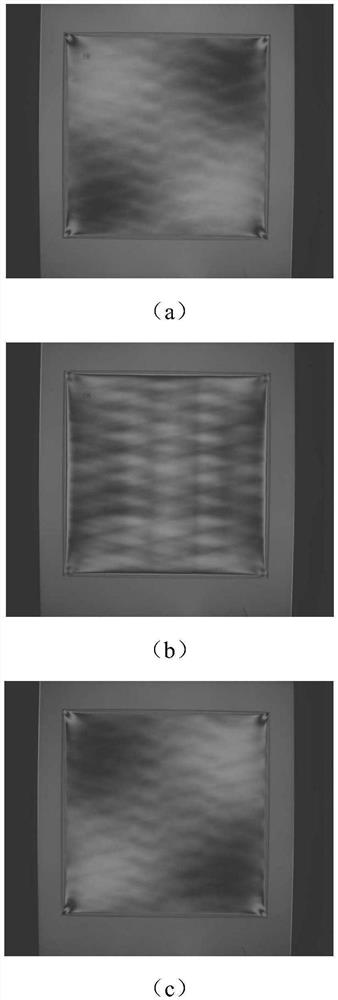

[0045] Step 1, use the UAV equipped with a pixel polarization camera and a circularly polarized light source to scan each area of the glass curtain wall to be inspected block by block, and obtain the reflective photoelastic fringe image of each area.

[0046] Use the UAV equipped with a pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com