Displacement metering pump and use of the displacement metering pump

A displacement metering and housing technology, applied in pumps, applications, kitchen utensils, etc., to achieve the effect of precise metering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

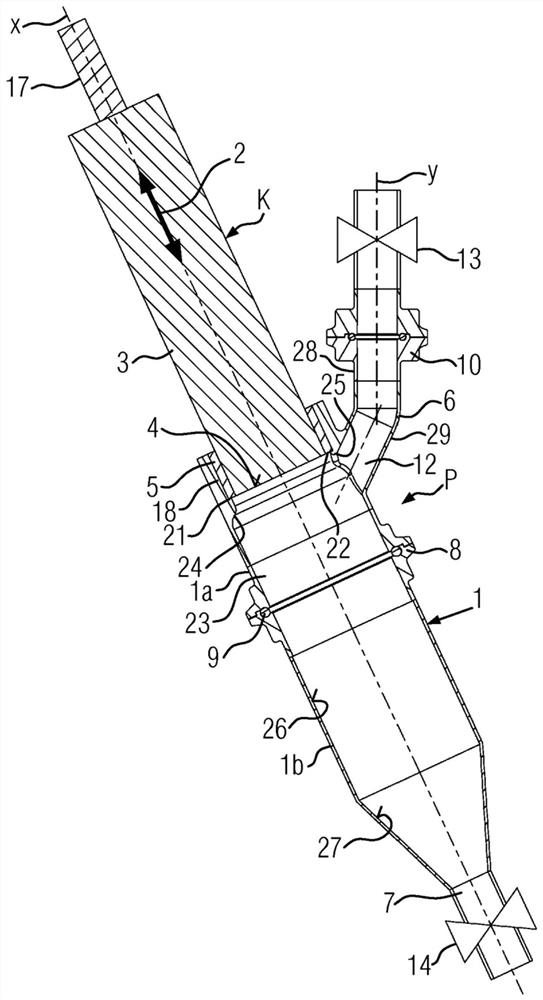

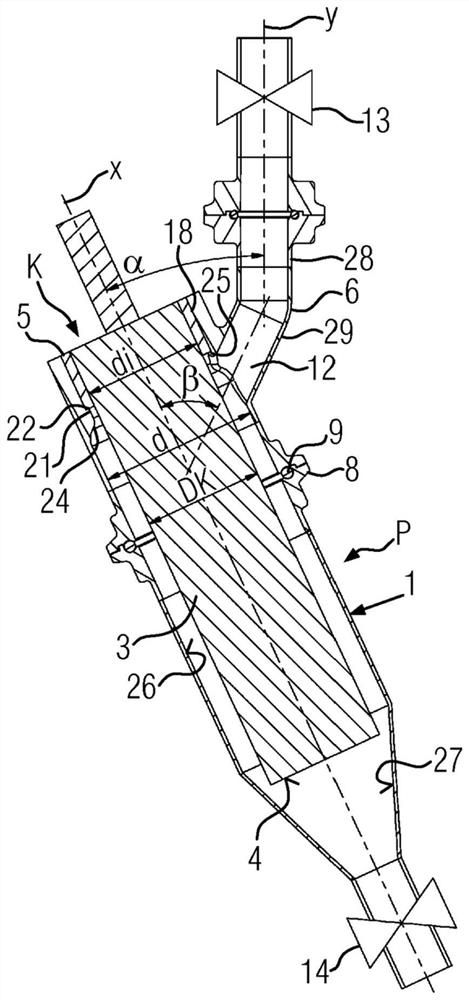

[0021] figure 1 and figure 2 Displacement metering pumps (displacement metering pumps) P, each of which is shown in cross-section, in particular displacement metering pumps for discrete volumetric metering of liquid to pasty products partially laden with solid matter, e.g. in the food industry The metering pump P can be mounted inclined in the operating position at an angle α of approximately 30°, for example, with respect to the vertical.

[0022] The displacement metering pump P includes, as main components, a tubular cartridge case 1 and a displacement piston K movable in the direction of the double arrow 2 inside the cartridge case 1 . The displacement piston K is embodied as a cylinder in its operating region and resembles a piston rod whose end 4 inside the cartridge housing 1 can be flat and substantially perpendicular to the cartridge axis X. The cartridge housing 1 is divided via a flange joint 8 with a seal 9 into a head 1 a and a bottom 1 b , where for example th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com