Automatic rainwater lifting device in underground rainwater pipeline and construction method

An automatic lifting and rainwater technology, applied in water supply devices, waterway systems, separation methods, etc., can solve problems such as unfavorable safety, rising rainwater, difficult evaporation of rainwater, etc., to achieve the effect of ensuring safety and avoiding deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

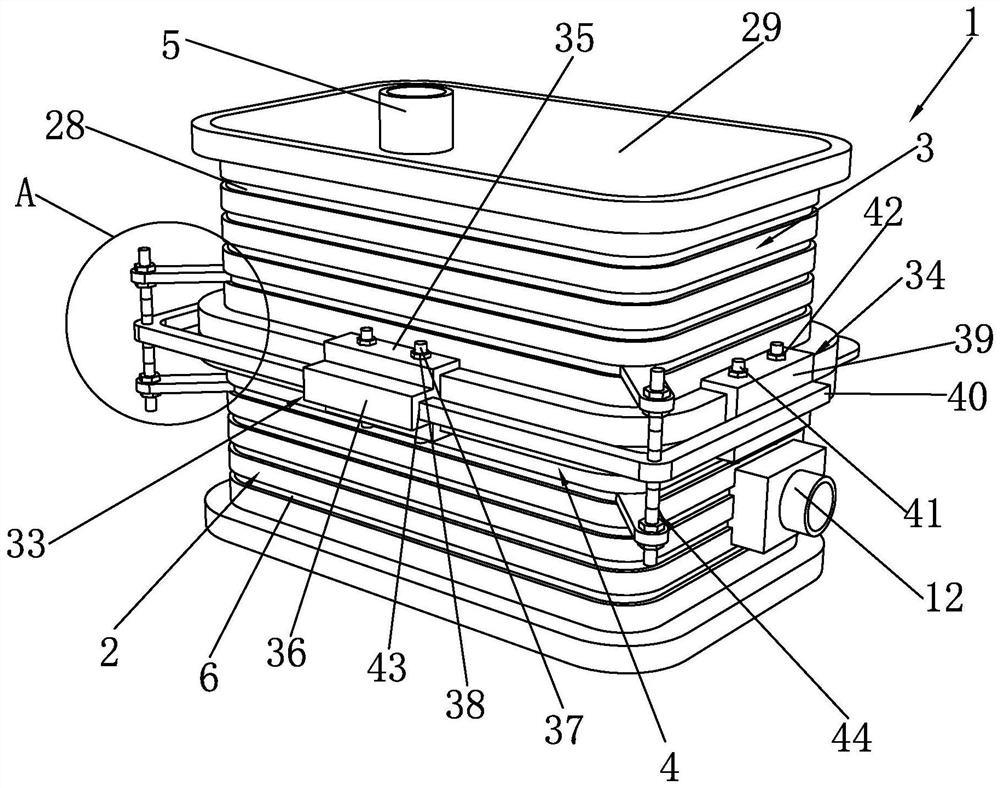

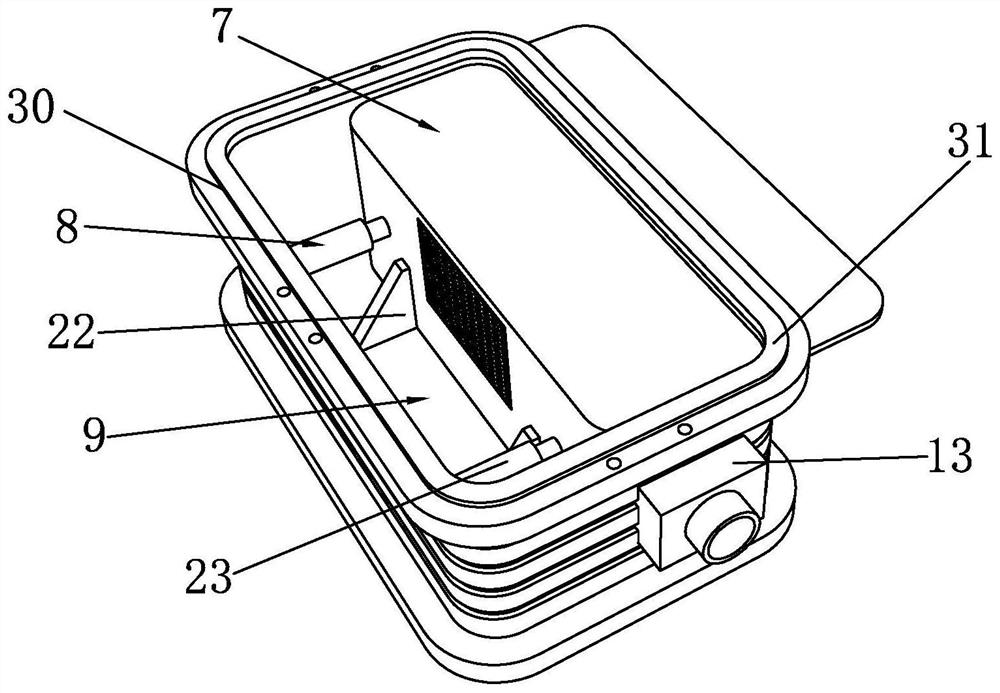

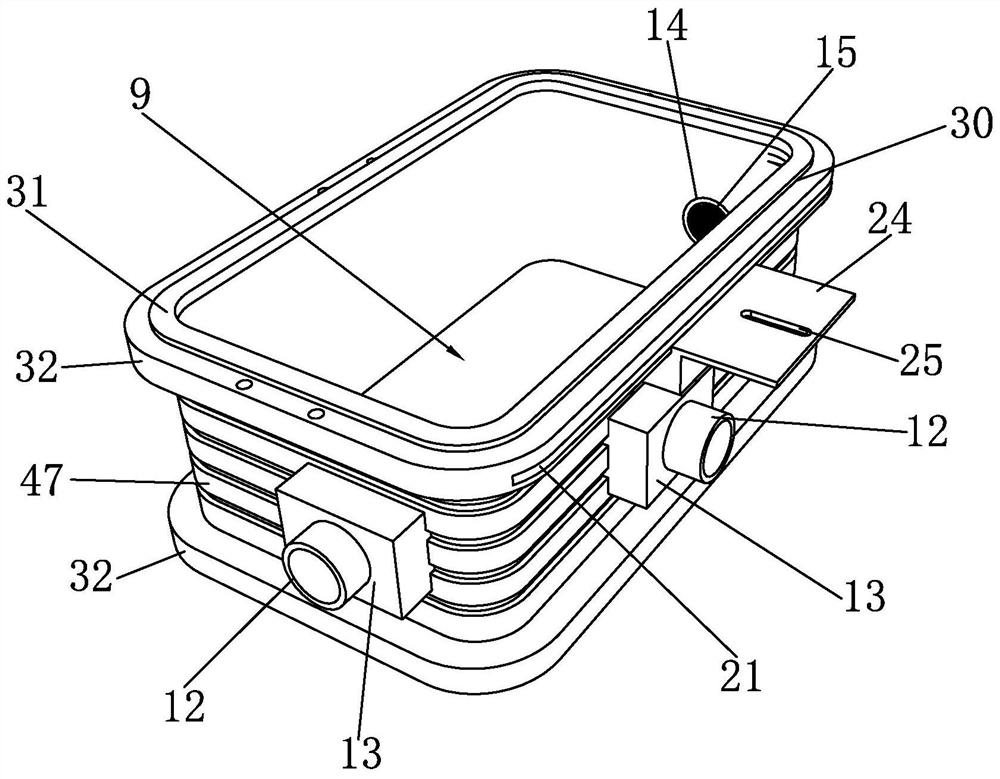

[0039] Such as Figure 1 to Figure 6 As shown, the rainwater automatic lifting device in the underground rainwater pipeline of the present invention includes a body 1, a collection mechanism 2 is provided at the bottom of the body 1, and a storage component 3 is superimposed on the top of the collection mechanism 2. The connection between the collection mechanism 2 and the storage component 3 A reinforcement component 4 is connected between them, a drainage pipe 5 is provided on the top of the storage component 3, and a drainage pump is provided in the drainage pipe 5. The collection mechanism 2 includes a collection box 6, a filter assembly 7 and an adjustment assembly 8. The collection box 6 is provided with a collection Cavity 9, filter assembly 7 and adjustment assembly 8 are all set in the collection chamber 9, the filter assembly 7 is movably connected to the adjustment assembly 8, the filter assembly 7 separates the collection chamber 9 into a water inlet tank 10 and a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com