Filling material self-building retaining wall and construction method

A filling and retaining wall technology, which is applied in the fields of filling, earthwork drilling, safety devices, etc., can solve the problems of slow construction efficiency and high cost of filling retaining walls, achieve simple structure, ensure anti-slip and anti-overturning capabilities, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

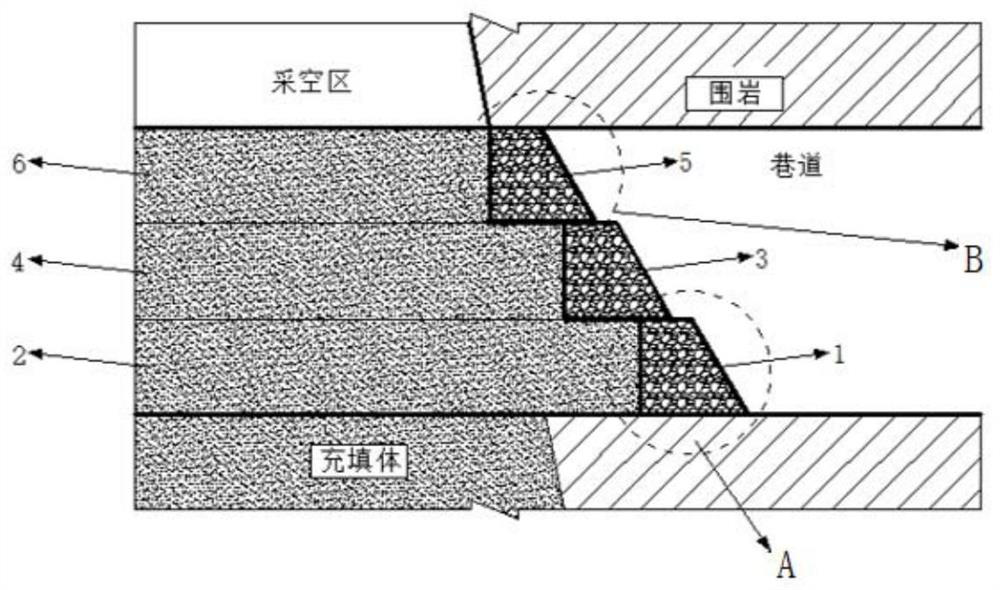

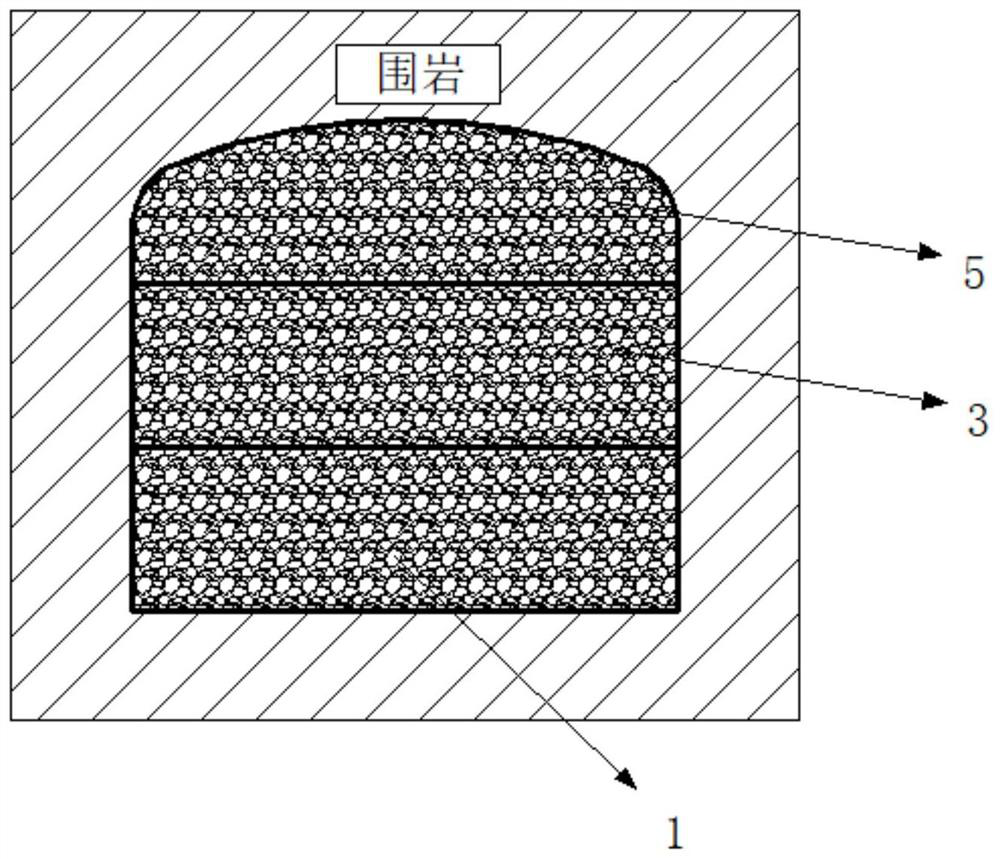

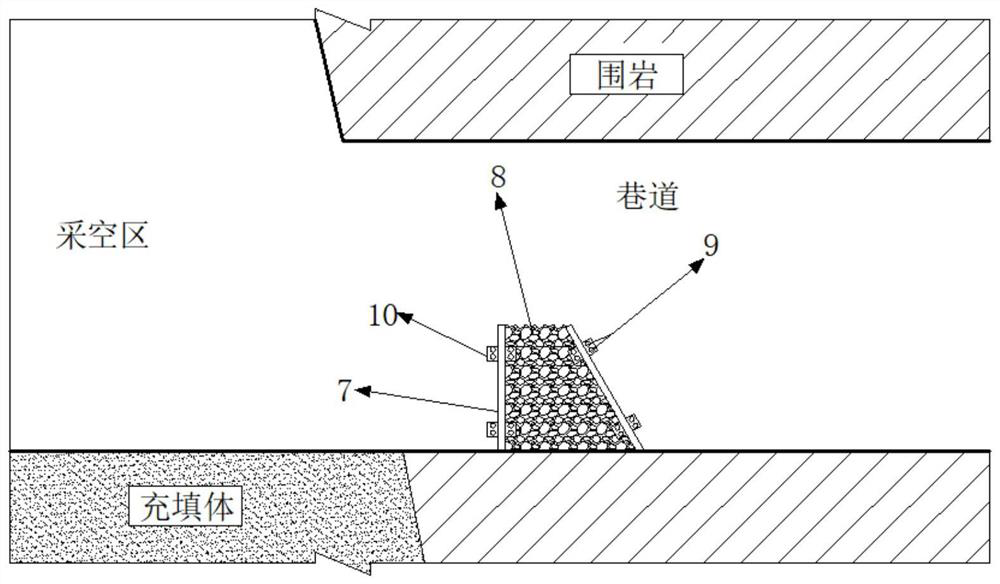

[0039] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, a self-built retaining wall with filling material includes several filling retaining walls arranged from bottom to top in the roadway. Several filling retaining walls are arranged in the roadway in a ladder shape. The stepped arrangement is convenient for each The construction of the layer filling retaining wall can effectively improve the construction efficiency. Each filling retaining wall body includes two baffles 7 that are oppositely arranged. Specifically, the two baffles 7 are separated by a certain distance. layout. The edges of the two baffles 7 are attached to the surrounding rock in the roadway, and the two baffles 7 and the surrounding rock form a trapezoidal filling space, and the filling space is filled with filling material 8, and the filling space is used as the outer frame of the filling retaining wall The filling material 8 is used as the internal filling material of the filling retain...

Embodiment 2

[0050] An iron mine in Anhui adopts the filling mining method for mining. The cross-section of the roadway is 5.0m long and 3.8m high. Firstly, choose a suitable position in the goaf joint roadway, that is, the roadway, to construct the bottom filling retaining wall body I1. The internal length of the filling space in the filling retaining wall body I1 is 5.0m (the actual width of the roadway). In order to ensure the construction efficiency of the retaining wall, the internal height h of the trapezoidal filling space is 1.5m. The top surface width a=0.54h is 0.8m, and the lower bottom surface width b=1.12h is 1.68m. Transport the filling material 8 in the adjacent goaf to the filling space, and maintain the filling retaining wall body I1 for 16 hours, so that the compressive strength of the retaining wall is 0.2 MPa. The first part of the filling retaining wall body I1 is filled after the maintenance is completed, and the filling height is consistent with the height of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com