A Thrust Balanced Structure

A technology of thrust balance and gas pipe, applied in the direction of machines/engines, blade support components, mechanical equipment, etc., can solve the problems of increasing unit loss, poor axial thrust bearing capacity, limiting the use of electromagnetic bearings and air bearings, etc. Achieve the effects of reducing friction loss, increasing safety, and strong ability to change working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

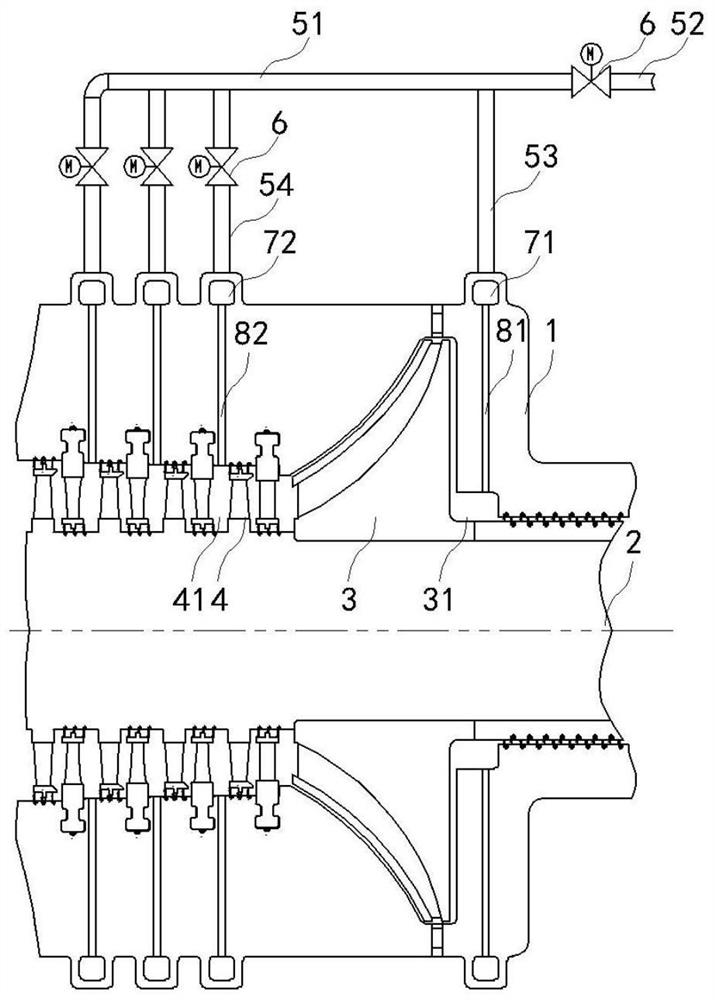

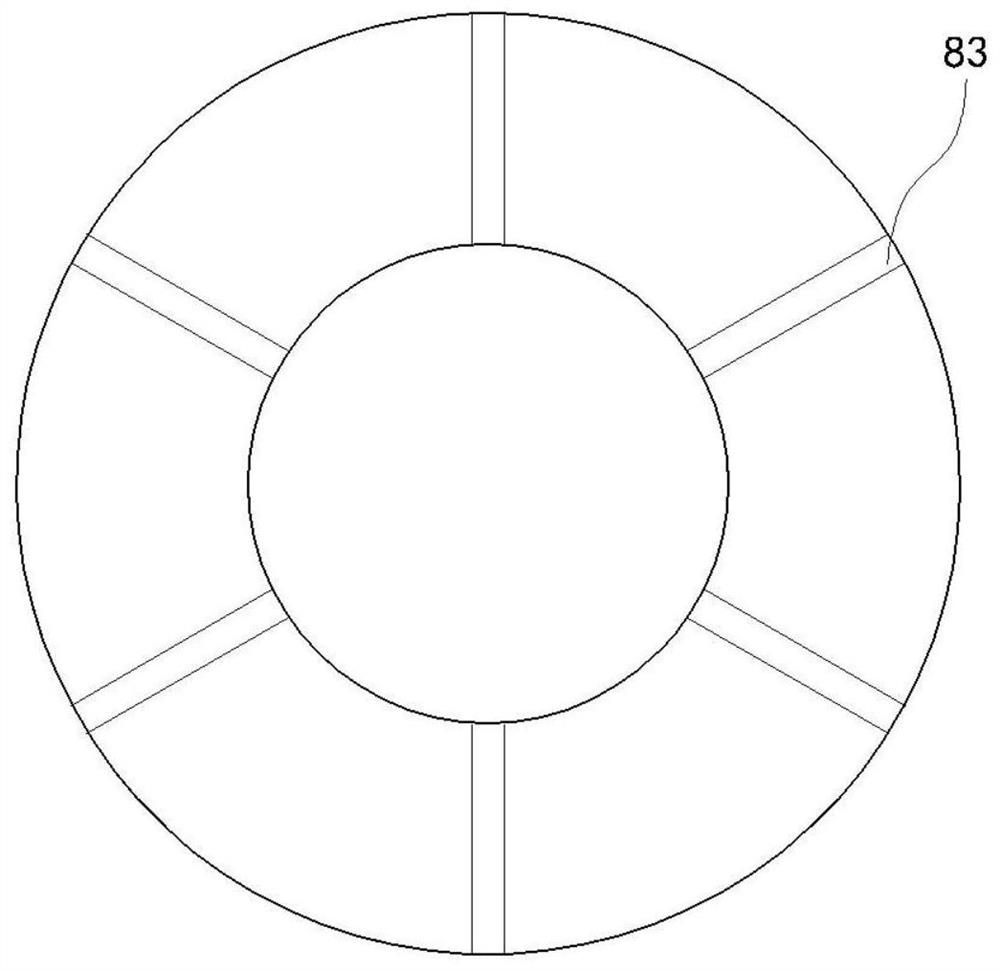

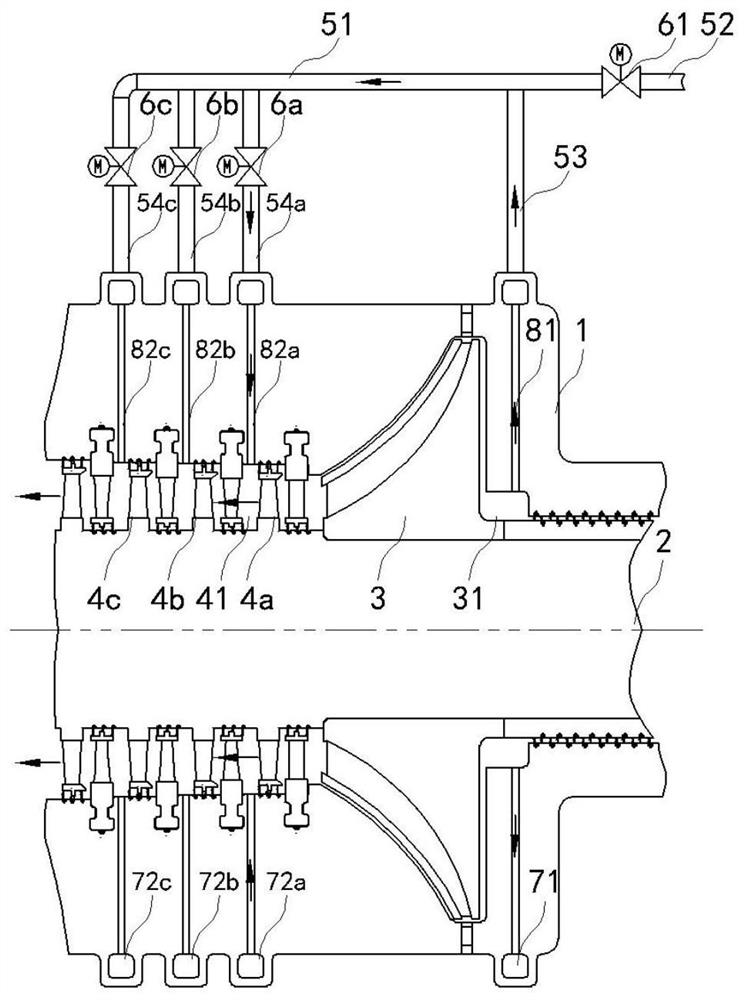

[0040] Such as Figure 1-2 As shown, a thrust balance structure of this embodiment includes a cylinder 1, a rotor 2 is arranged in the cylinder 1, and a centripetal impeller 3, a first movable blade cascade 4a, a second movable blade cascade 4b and a third movable blade cascade are arranged in sequence on the rotor 2 moving blade cascade 4c;

[0041] The air inlet pipe 52, the impeller air pipe 53, the first cascade air pipe 54a, the second cascade air pipe 54b and the third cascade air pipe 54c are connected through the air pipe 51; The regulating valve 61, the first electric regulating valve 6a, the second electric regulating valve 6b, and the third electric regulating valve 6c are respectively arranged on the first cascade air pipe 54a, the second cascade air pipe 54b, and the third cascade air pipe 54c;

[0042] The impeller air pipe 53, the first cascade air pipe 54a, the second cascade air pipe 54b, and the third cascade air pipe 54c are respectively connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com