Aluminum material extruding machine with automatic material conveying structure and using method of aluminum material extruding machine

An aluminum extruder and automatic conveying technology, which is applied in the field of aluminum extruders, can solve problems that affect production safety, easily cause production accidents, affect processing efficiency and product quality, and improve safety and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

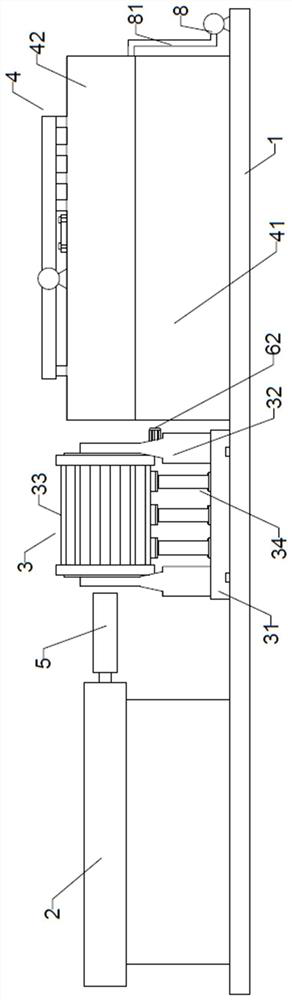

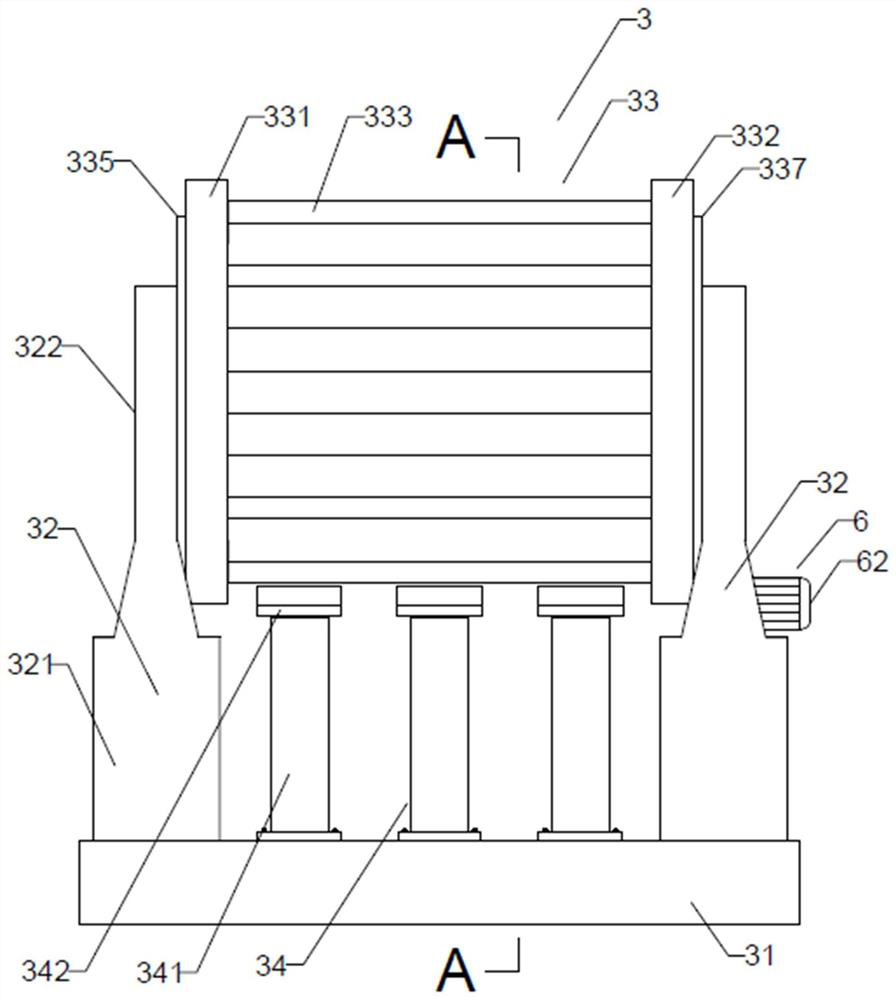

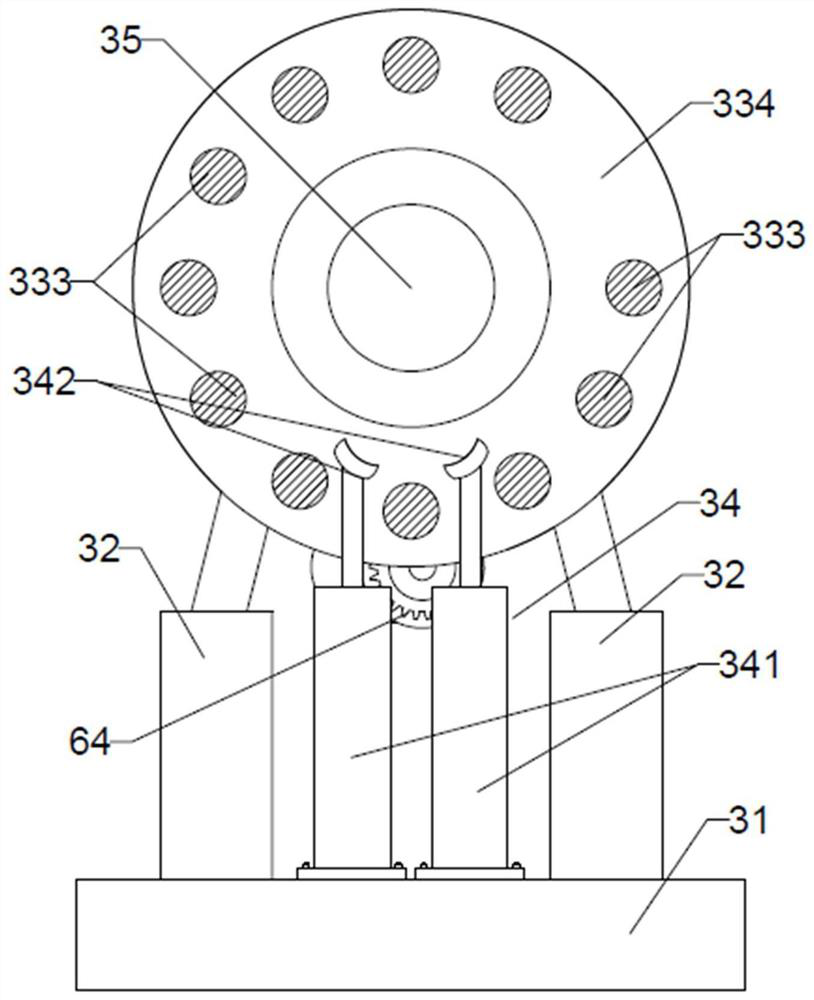

[0034] like Figure 1-5 The shown aluminum extruder with automatic conveying structure includes workbench 1, extrusion hydraulic cylinder 2, conveying mechanism 3, extruder body 4, said extrusion hydraulic cylinder 2 and extruder body 4 Fixed on the workbench 1, the extruding hydraulic cylinder 2 is provided with an extruding column 5 near the end of the extruder body 4; the conveying mechanism 3 is movably arranged on the workbench 1, Press the hydraulic cylinder 2 and extruder body 4 to move in the direction of the line; the conveying mechanism 3 includes a moving base 31, a group of feeding brackets 32, a feeding rolling cage 33, a group of lifting mechanisms 34, and the moving base 31 is set on the workbench 1, the feeding rolling cage 33 is fixed on the moving base 31 through the feeding bracket 32, and the lifting mechanism 34 is set on the moving base 31, symmetrically arranged along the axis of the feeding rolling cage 33 ; The axial sides of the feeding rolling cage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com