Connector type steel pipe scaffold

A scaffolding and joint-type technology, which is applied in the connection of scaffolding, building structure support, building structure support, etc., can solve the problems of installation and removal of vertical poles, inconvenient transportation and stacking, and non-interchangeable poles, etc., to achieve energy saving and increase Obvious effect, light weight, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

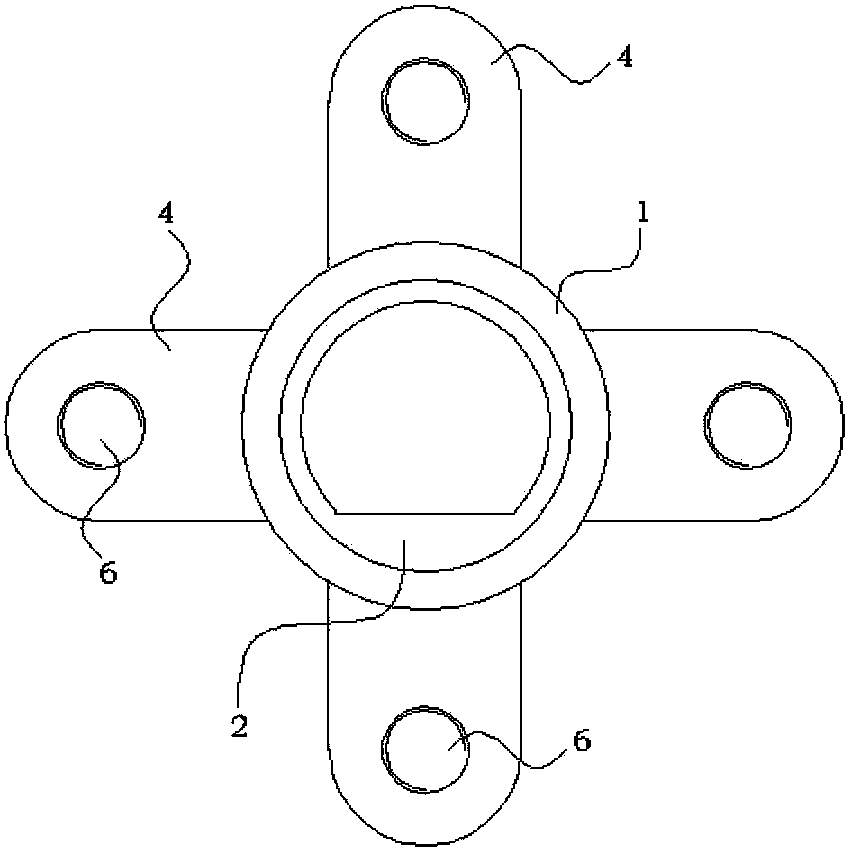

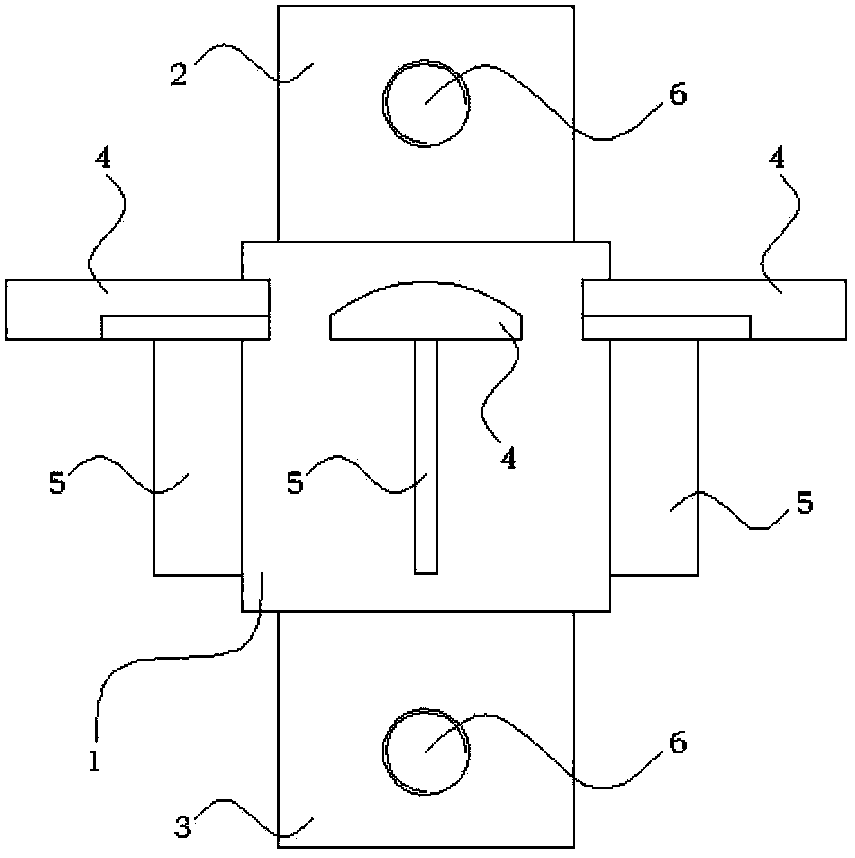

[0039] Such as figure 1 As shown in -19, a joint-type steel pipe scaffolding includes steel pipes, joints, jacking wires, connecting plates, diagonal bracing joints, and cantilever joints connected by bolts to the frame body of the diagonal bracing scaffolding. The joint is composed of a round pipe (1), an upper round pipe (2), a lower round pipe (3), a bow-shaped plate (4) and a stiffening plate (5). Bolt holes (6) are arranged on the upper round pipe (2), the lower round pipe (3) and the arcuate plate (4).

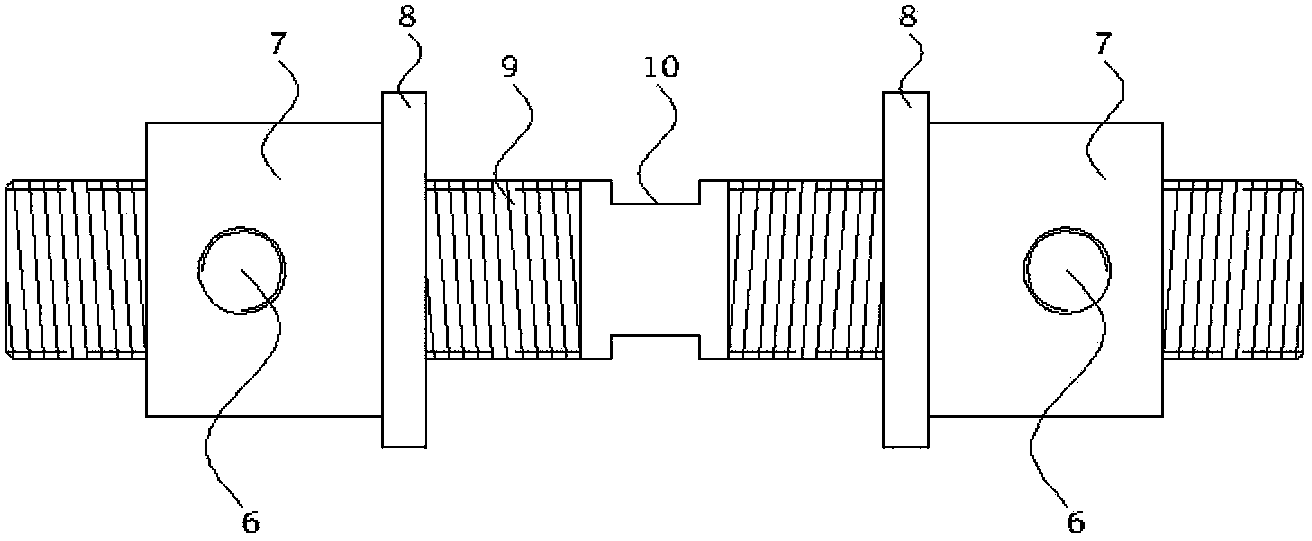

[0040] The top wire is made up of a leading screw (9) and two top screw caps. A wrench groove (10) is set in the middle of the leading screw (9). The top screw cap is made up of a small cylinder (7) and a large cylinder (8), and two bolt holes (6) are arranged on the small cylinder (7). There is an M24 bolt hole in the middle of the top screw ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com