Patents

Literature

34results about How to "Won't cause an accident" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

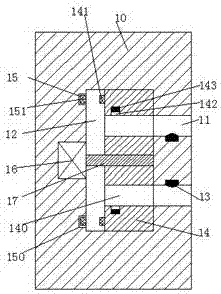

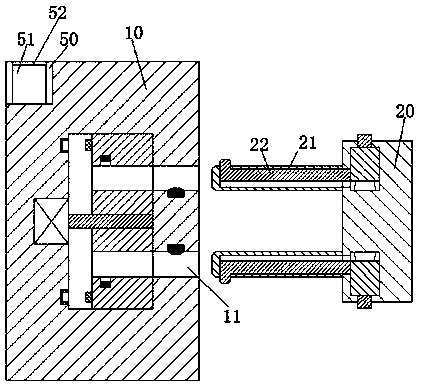

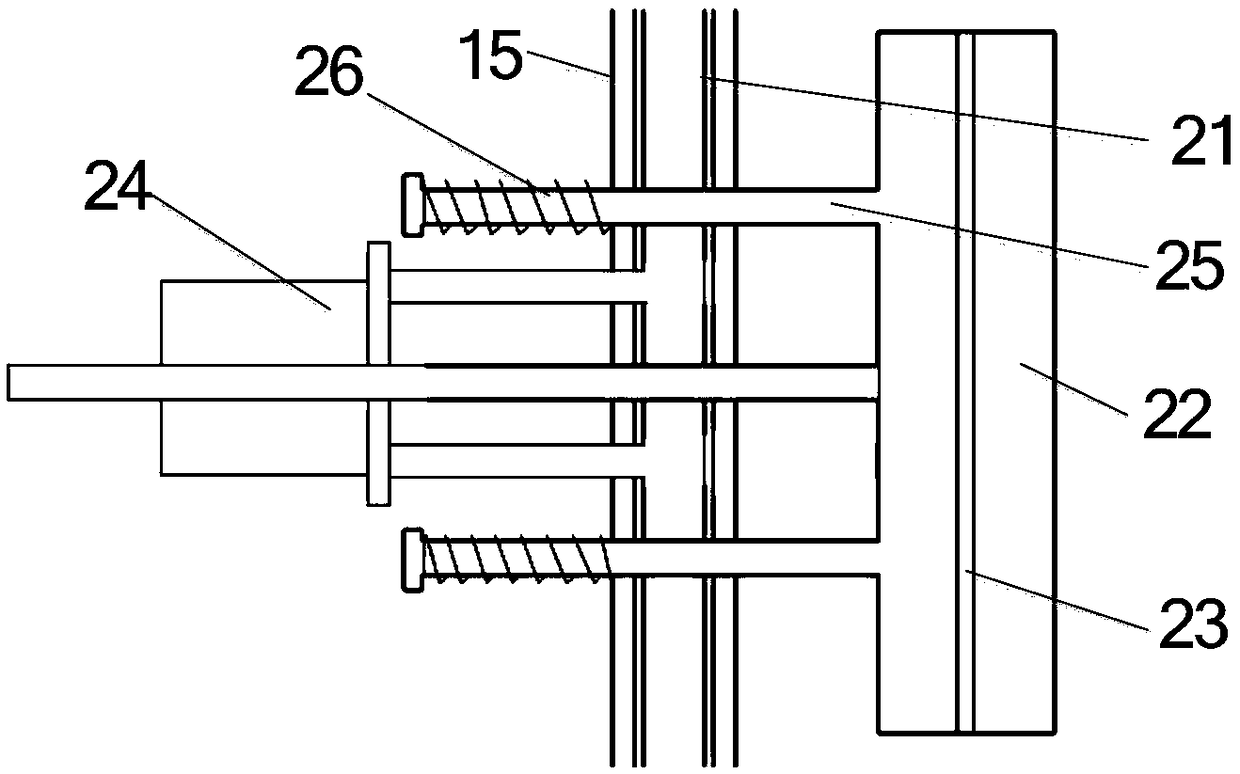

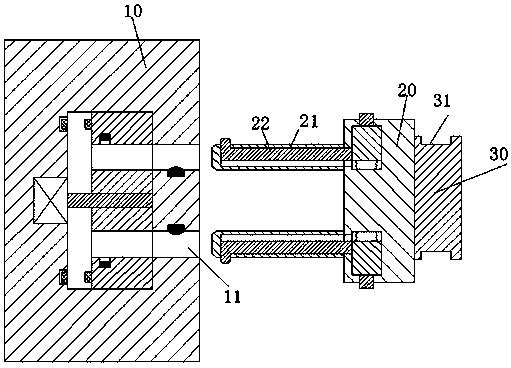

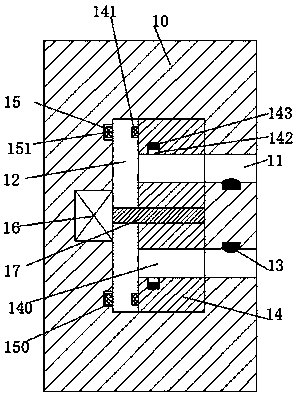

Safety plugging-connection mechanism for electrical appliance energization

InactiveCN107681363AWon't cause an accidentAchieve electrificationTwo-part coupling devicesLive contact access preventionElectricityEngineering

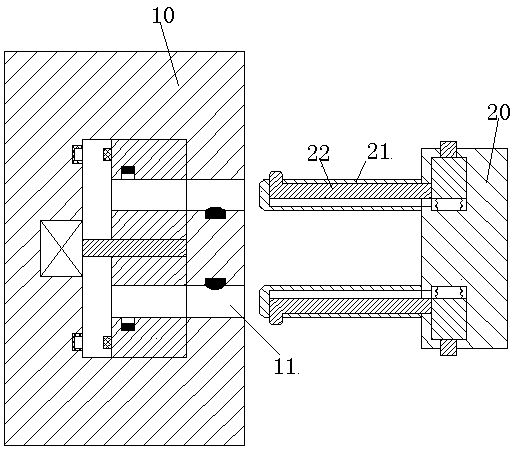

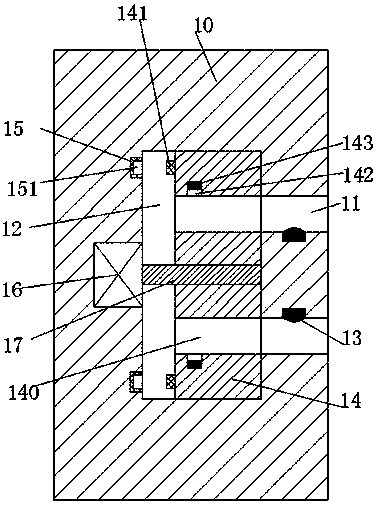

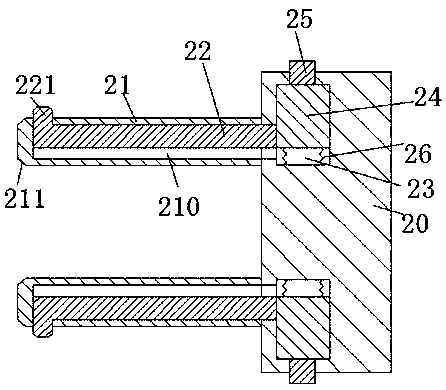

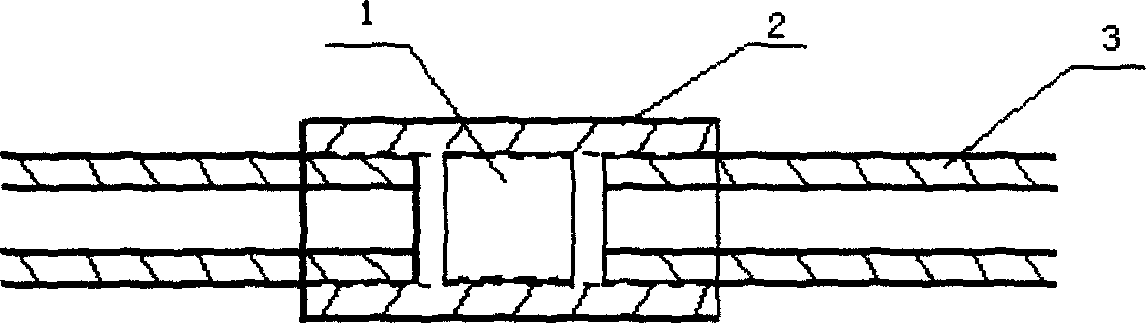

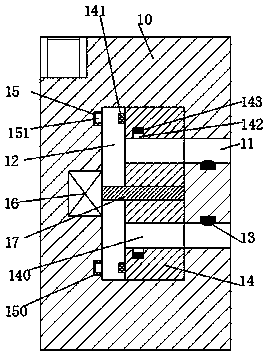

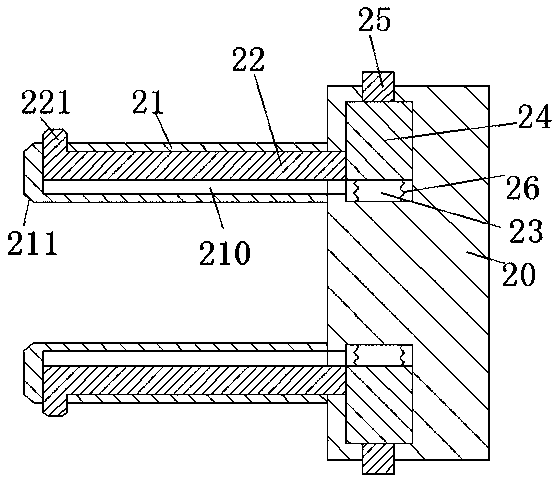

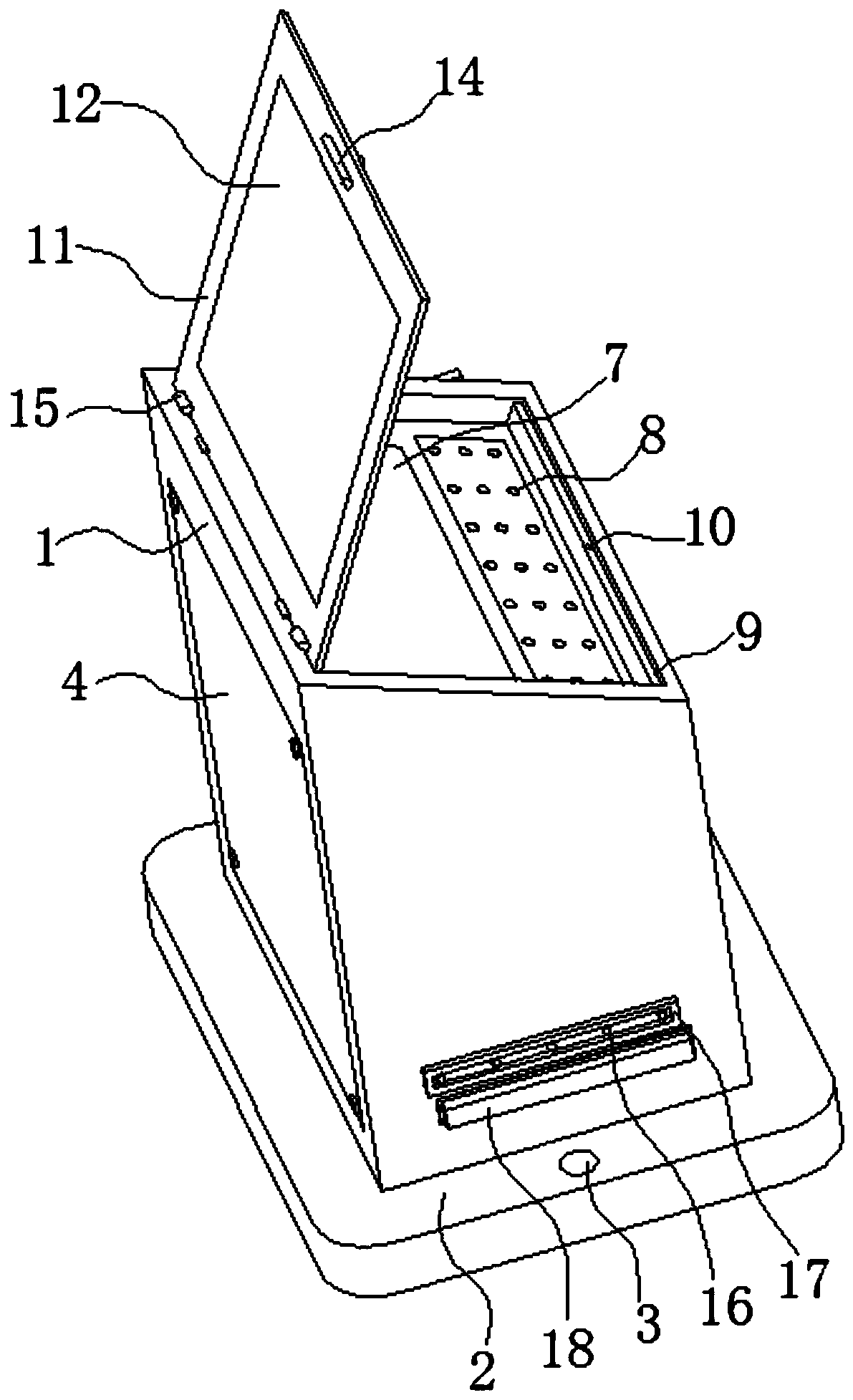

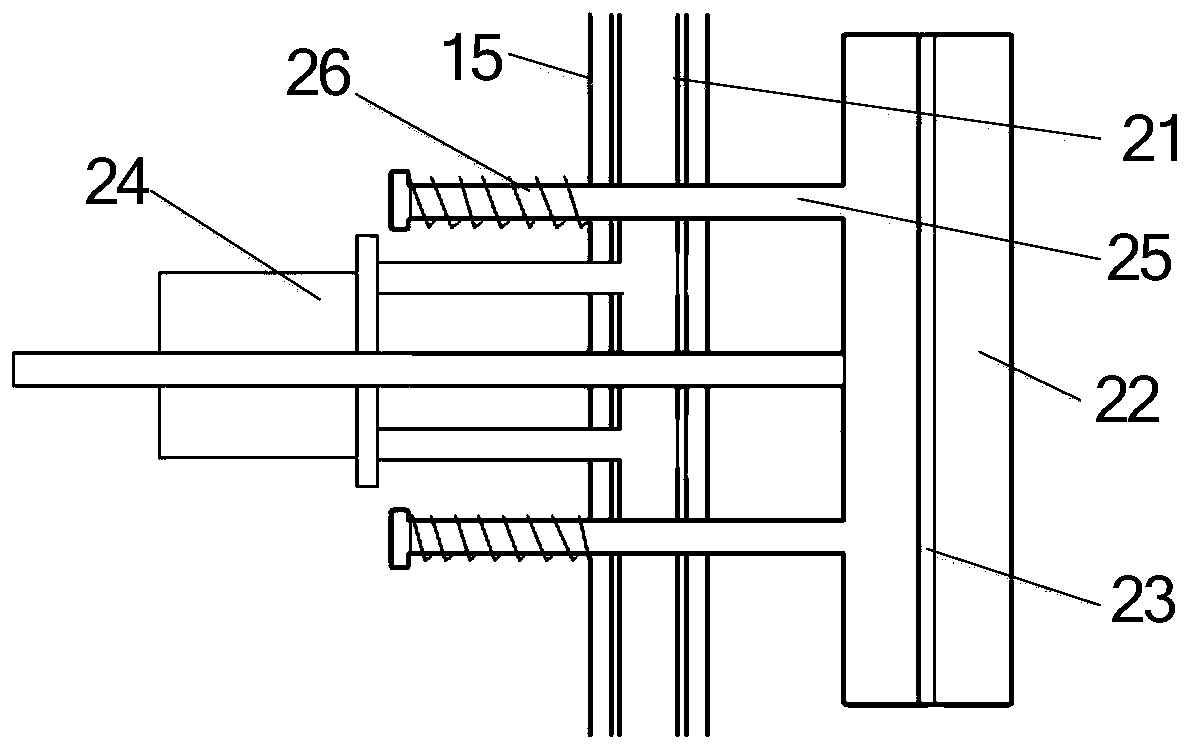

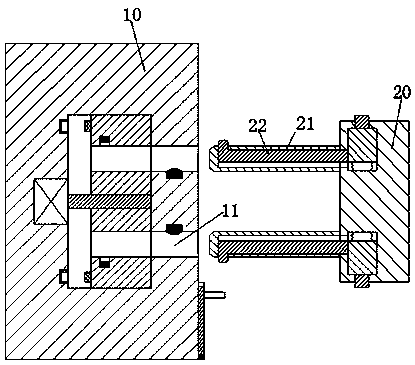

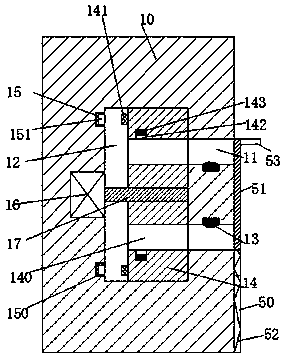

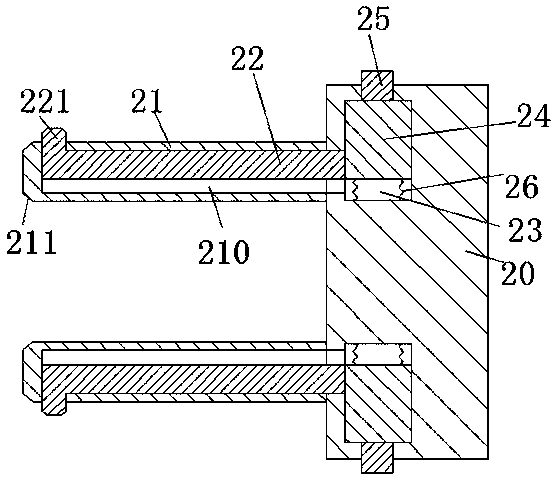

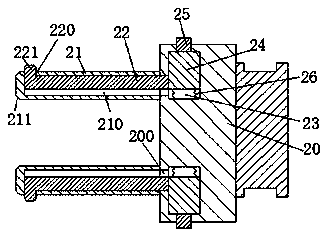

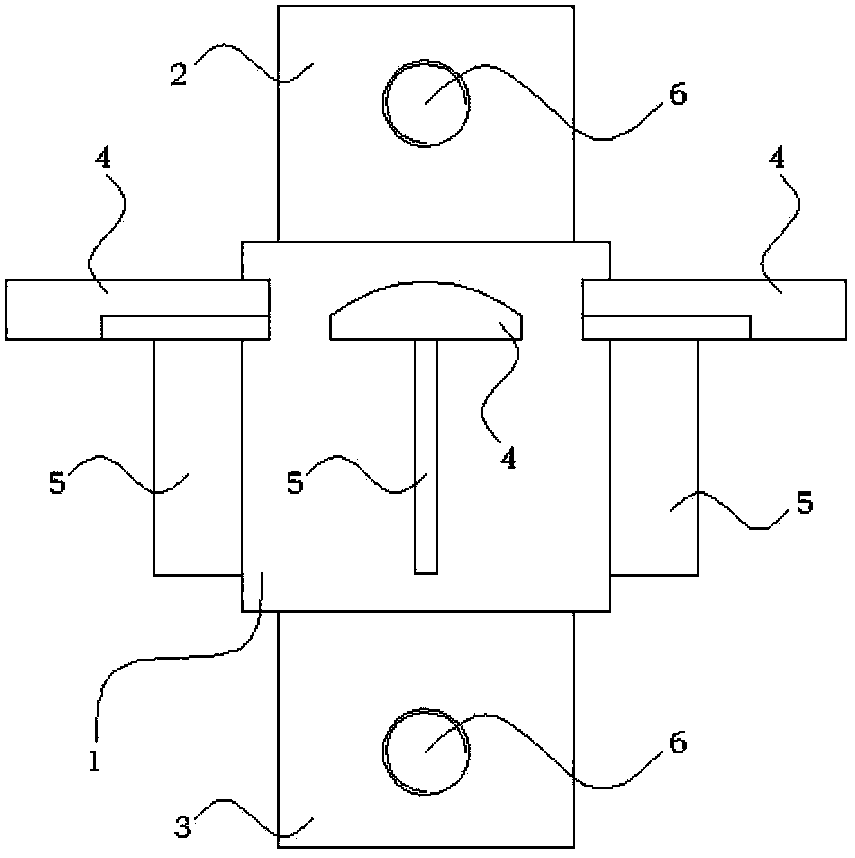

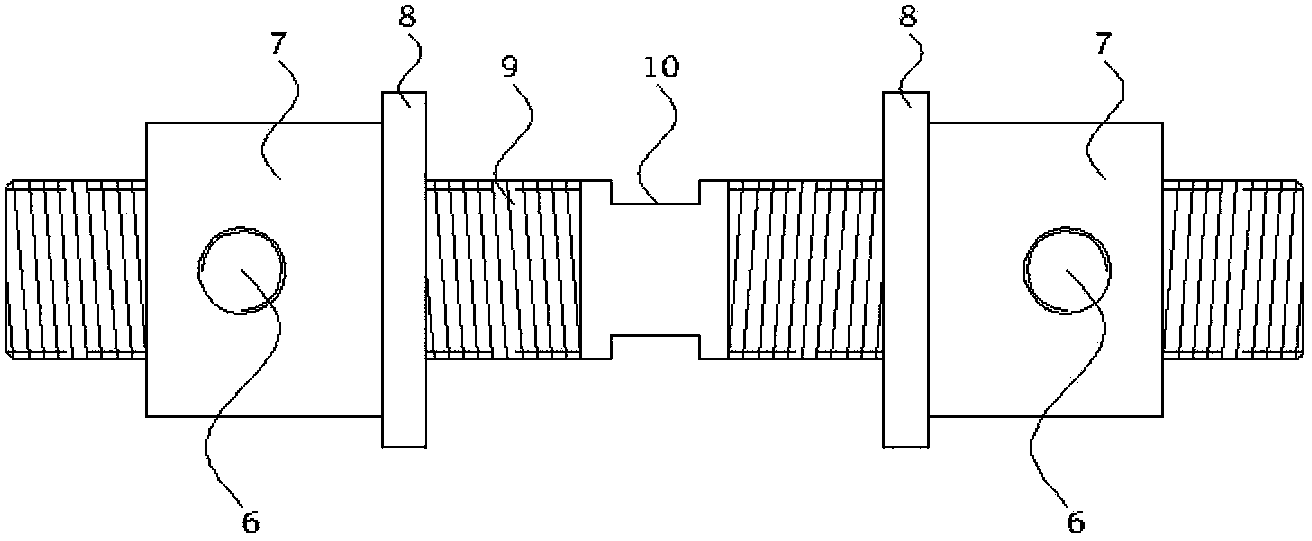

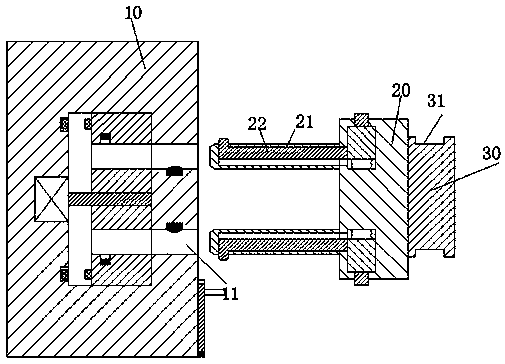

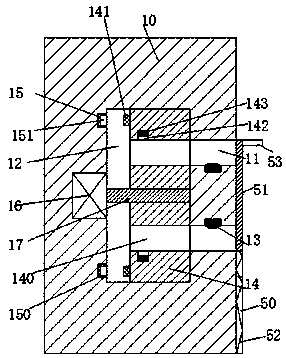

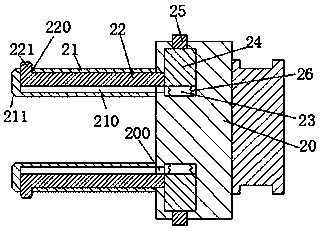

The invention provides a safety plugging-connection mechanism for electrical appliance energization. The safety plugging-connection mechanism comprises a plugging-connection seat and a plugging-connection head; a sliding-connection cavity is defined in the plugging-connection seat; plugging-connection grooves which are communicated with the outside and are distributed symmetrically in a vertical direction are formed in the right end surface of the sliding-connection cavity; a sliding-connection frame is mounted in the sliding-connection cavity in a leftward-and rightward-slideable manner; through grooves which extend in a left-and-right direction and are distributed symmetrically in a vertical direction are formed in the sliding-connection frame; a threaded rod is mounted in the sliding-connection frame through screw-thread fit; the right end of the threaded rod is rotatably installed in the right end wall of the sliding-connection cavity; the left end of the threaded rod is in matchedconnection with a motor fixedly installed in the left end wall of the sliding-connection cavity; first grooves which are symmetrically arranged in a vertical direction are formed in the left end wallof the sliding-connection cavity; power supply blocks connected with mains supply are fixedly mounted in the first grooves; plugging-connection openings facing the sliding-connection frame are formedin the power supply blocks; conductive blocks which are matched with the plugging-connection openings and are symmetrically distributed in a vertical direction are arranged on the left end surface ofthe sliding-connection frame; elastic conductive blocks are fixedly mounted in the inner side end walls of the plugging-connection grooves; second grooves are formed in the outer side end surfaces ofthe through grooves; and contact switches connected with the motor are mounted in the second grooves.

Owner:陈志桂

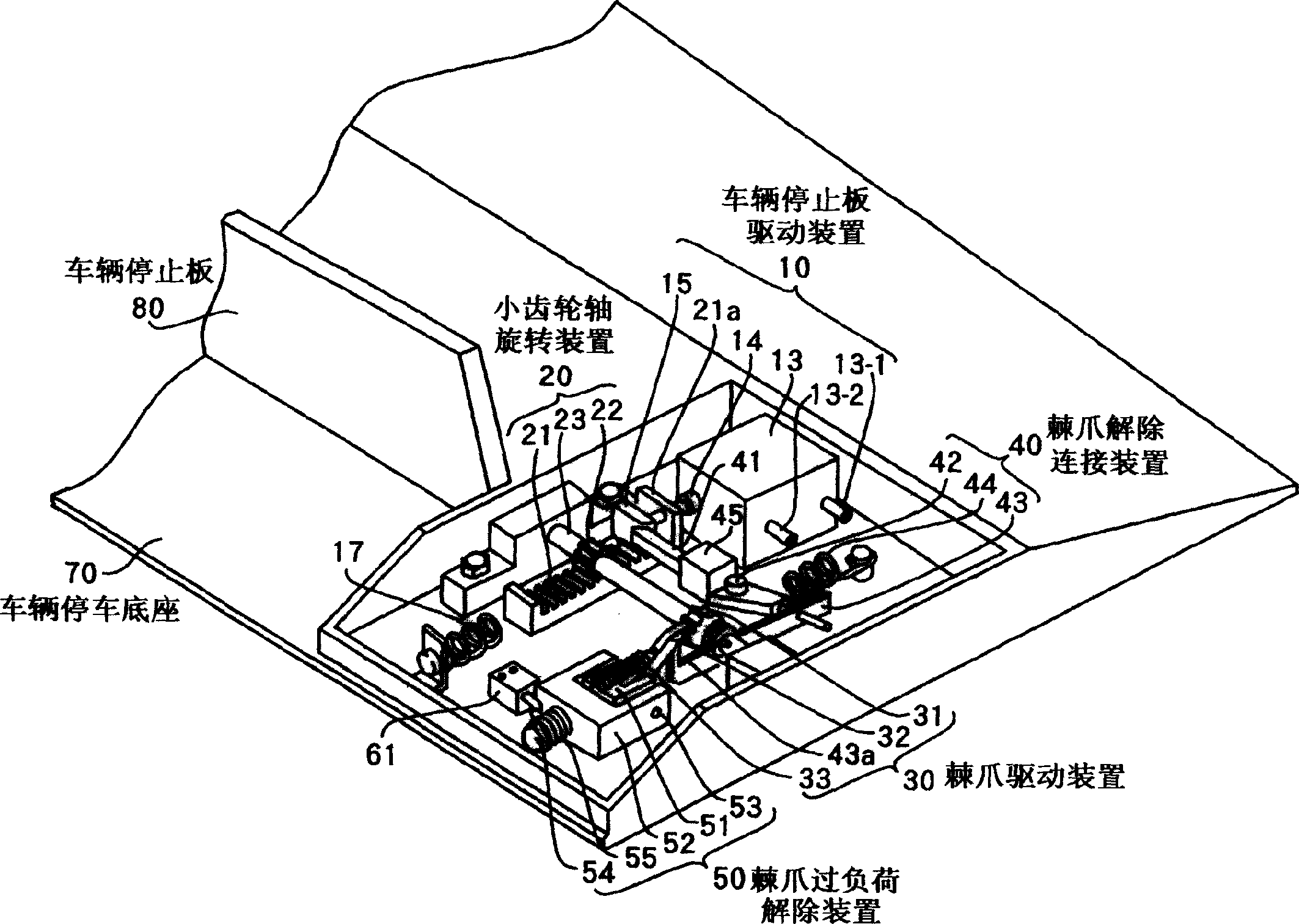

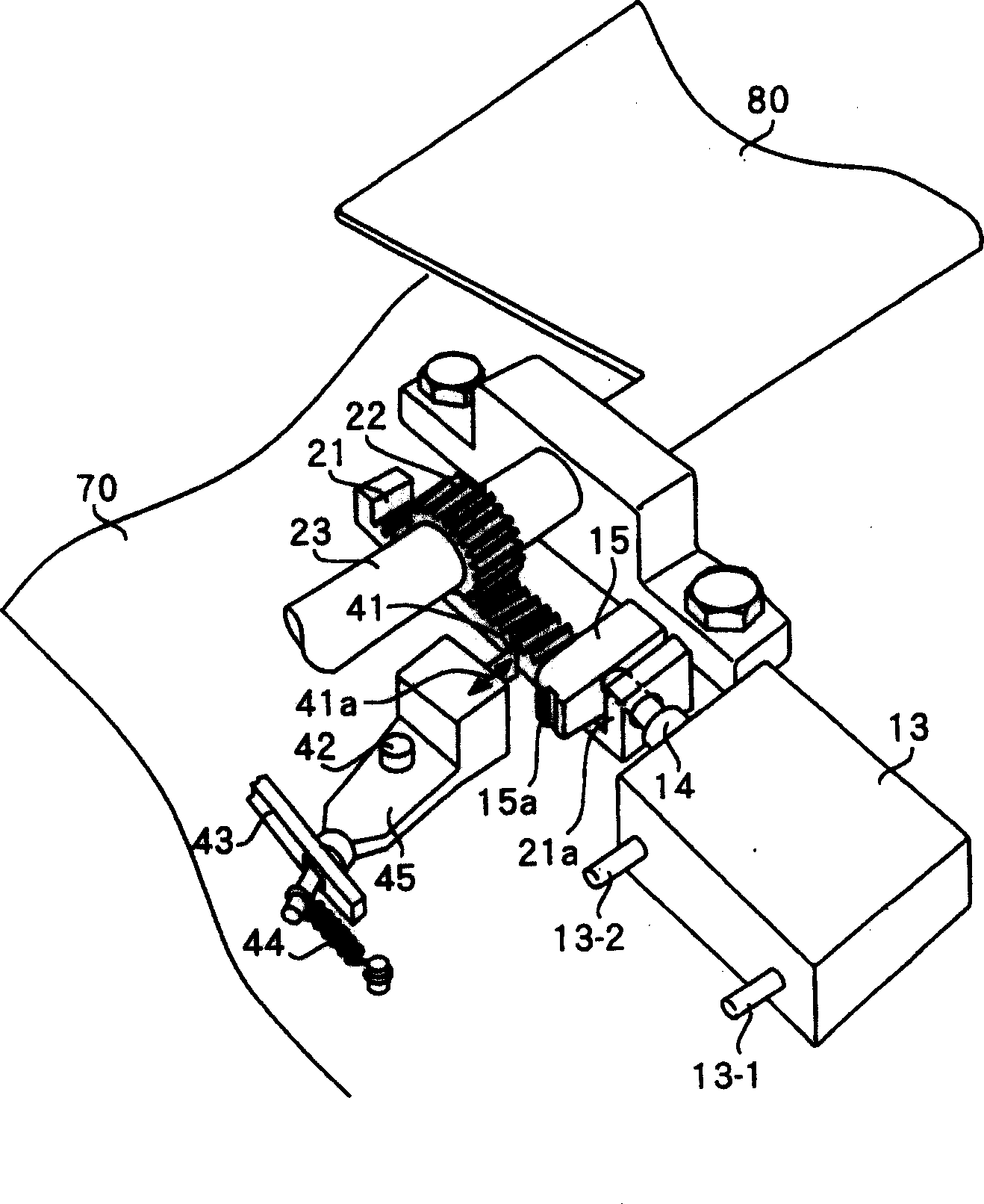

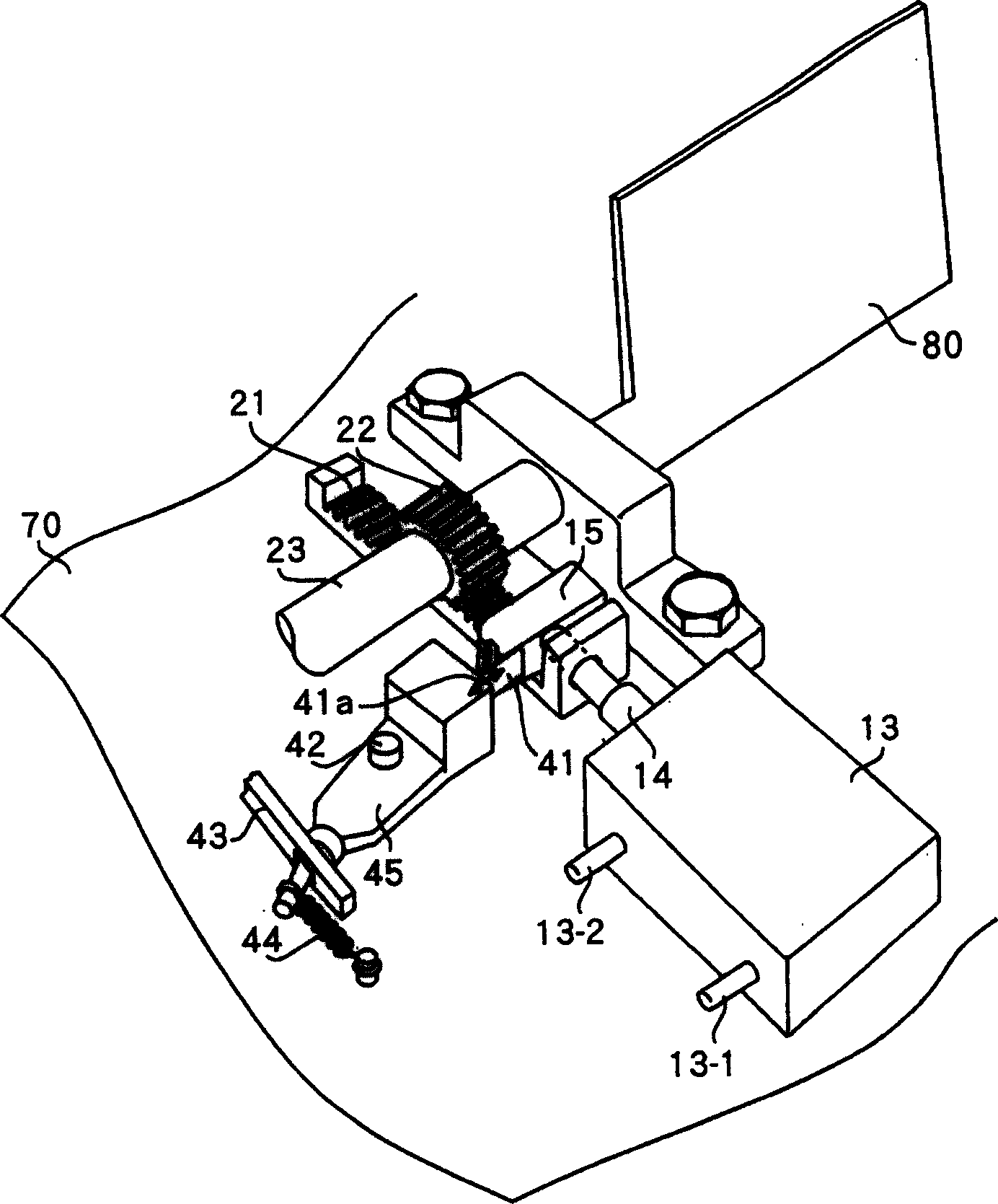

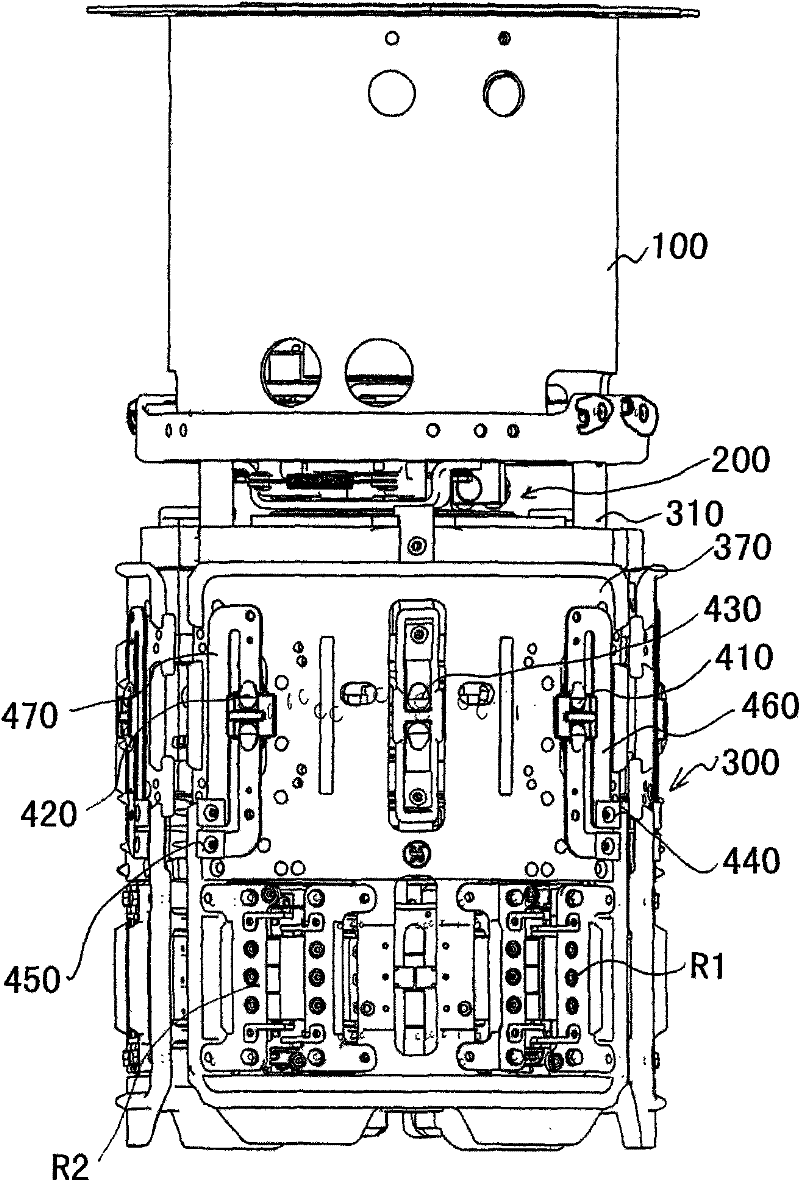

Parking vehicle fixing device

InactiveCN1637222ACushion the shockStop smoothTraffic restrictionsParkingsPinionAutomotive engineering

PROBLEM TO BE SOLVED: To provide a parking vehicle fixing device capable of detecting an artificial illegal escape by preventing damage to the device, when a strong external force is applied to a rising vehicle stopping panel, by relieving an impact when touching a vehicle bottom surface when the vehicle stopping panel rises in response to the aboveground lowest height of each vehicle, while simplifying the device by uplifting and letting down the vehicle stopping panel by one cylinder. SOLUTION: A rack 21 is advanced by delivering a rod 14 of an air cylinder 13, and the vehicle stopping panel 80 is uplifted by rotating a pinion 22. In an uplifted position, a ratchet 32 meshes with a ratchet wheel 31, and the vehicle stopping panel 80 is held. The vehicle stopping panel 80 is let down by removing the ratchet 32 from the ratchet wheel 31 by operating a ratchet release connecting means 40 by retreating the rod 14 of the air cylinder 13. COPYRIGHT: (C)2005,JPO&NCIPI

Owner:交通システム電機

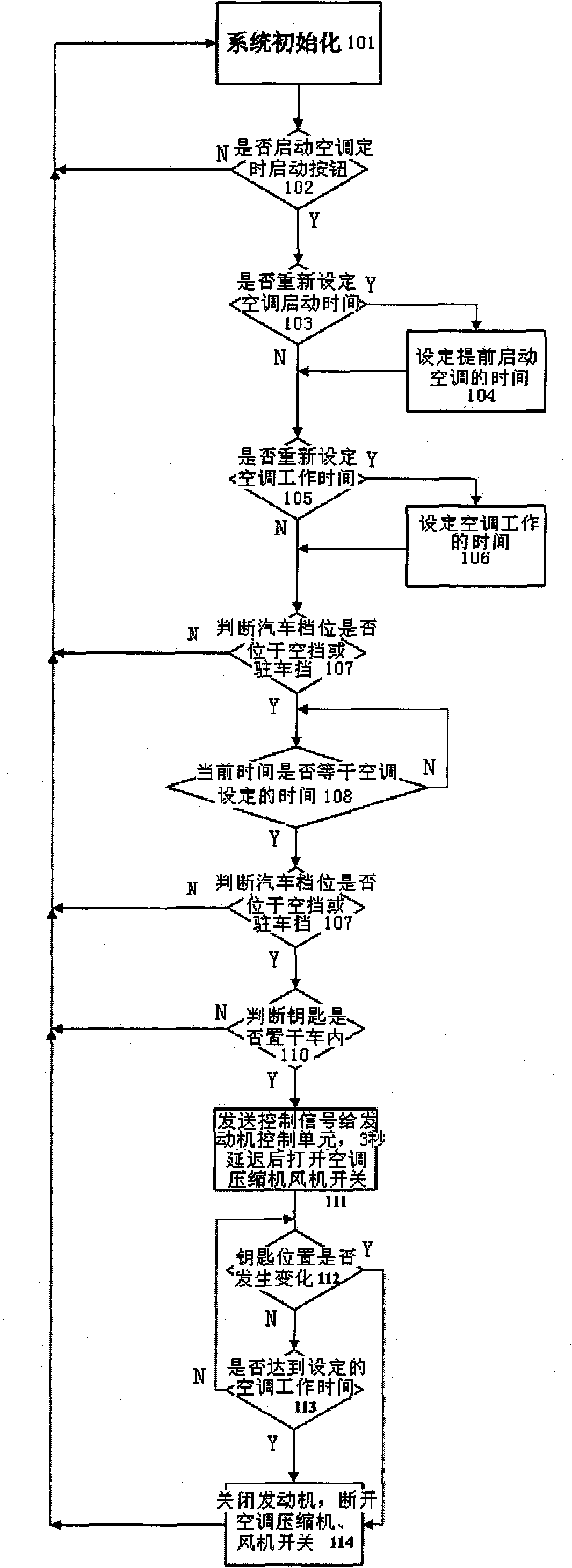

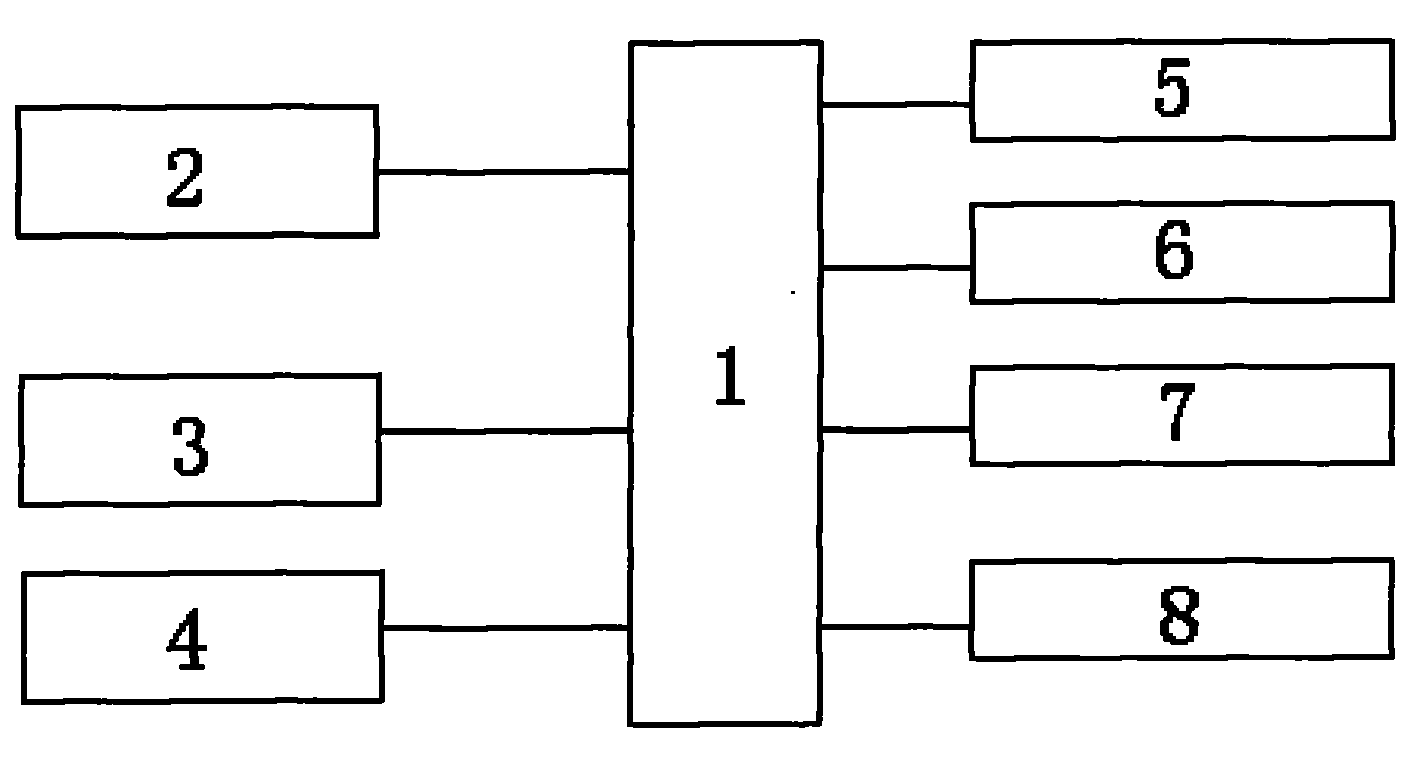

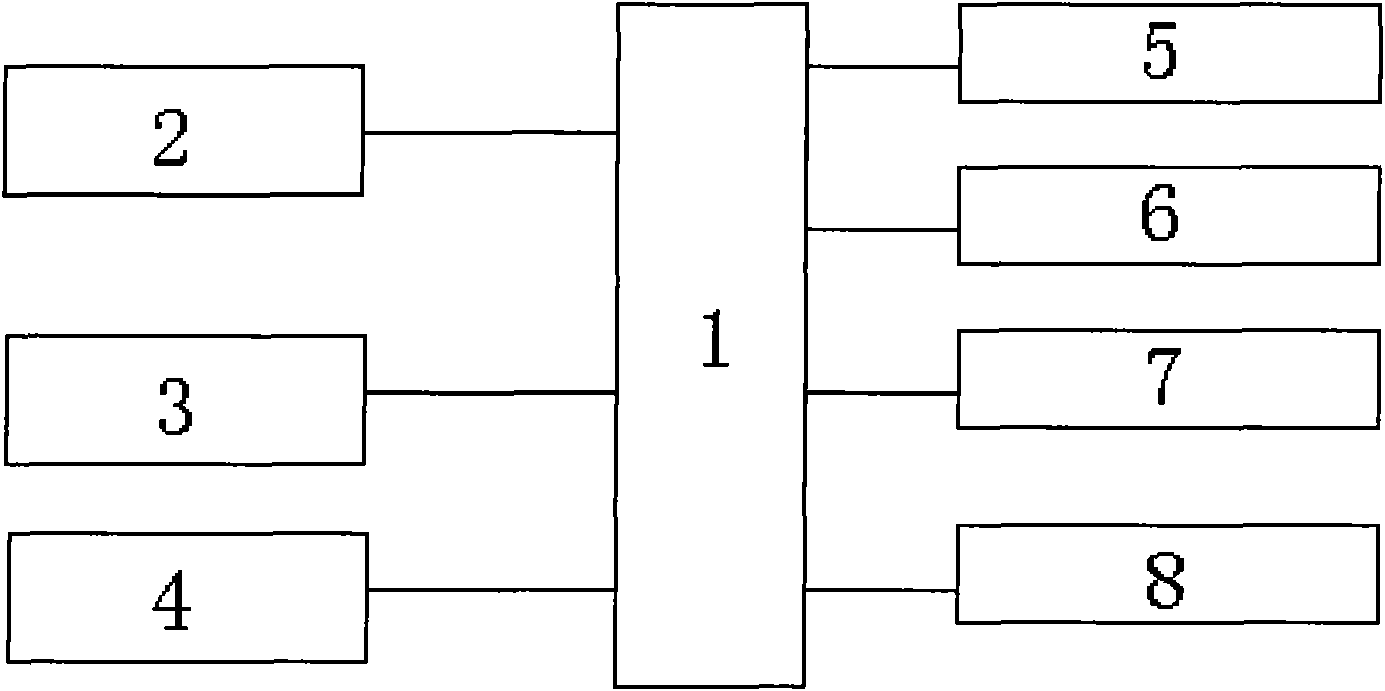

Timed starting system and starting method for automobile air conditioning

InactiveCN101811483ARealize advance adjustmentWon't cause an accidentAir-treating devicesVehicle heating/cooling devicesAutomobile air conditioningSystem development

The invention discloses a timed starting system and a timed starting method for an automobile air conditioning. The timed starting system comprises an instrument microprocessor, an engine management unit, an air conditioning compressor switch, an air conditioning fan switch and an instrument display screen, and is characterized in that: a clock adjusting button, an air conditioning starting button and an automobile gear input are arranged in the timed starting system of the automobile air conditioning and connected to the instrument microprocessor respectively; and the instrument microprocessor is connected with the engine management unit, the air conditioning compressor switch, the air conditioning fan switch and the instrument display screen respectively. Because the structure and the method are adopted in the invention, the system has the advantages that: 1, the automobile can automatically start the engine and the air conditioning switch according to the preset time so as to realize advanced adjustment of the temperature in the automobile and prevent conventional manual adjustment; 2, because multi-layer judgment is adopted in the program, the system is safe and reliable to use and cannot cause accidents by starting the engine for adjusting the temperature; and 3, the system has low development cost.

Owner:ATECH AUTOMOTIVE WUHU

Large-capacity miniature information storage device

InactiveCN107508100AWon't cause an accidentAchieve electrificationCoupling device detailsComputer periphery connectorsEngineeringLarge capacity

A large-capacity micro-information storage device of the present invention includes a reading socket and a plug-and-socket head. The reading socket is provided with a sliding cavity, and the upper and lower sides of the right side of the sliding cavity are correspondingly provided with plug-in sockets that communicate with the outside. A sliding frame is installed in the sliding cavity so that it can slide left and right, and the upper and lower sides of the sliding frame are correspondingly provided with left and right connecting grooves. It is installed in the right side of the sliding cavity, and the left end is connected with the motor fixedly installed in the left side of the sliding cavity. The left side of the sliding cavity is provided with first inserting grooves up and down correspondingly, and the first inserting groove is fixedly installed in the first inserting groove. There is a power supply end connected with the power source, and the power supply end is provided with an insertion and fixing port whose mouth is opposite to the sliding frame. A power transmission elastic block is fixedly installed in the inner side surface of the fixing groove, a second inserting groove is arranged on the outer side surface of the connecting groove, and a contact operating part connected with the motor is installed in the second inserting groove.

Owner:陈旭东

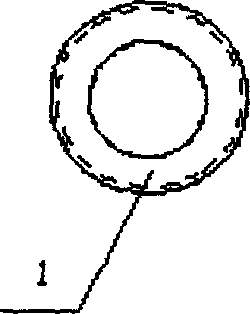

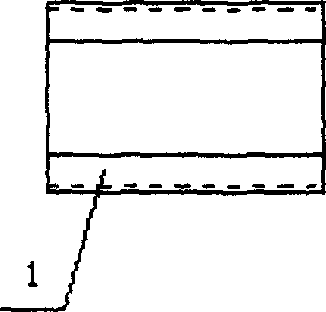

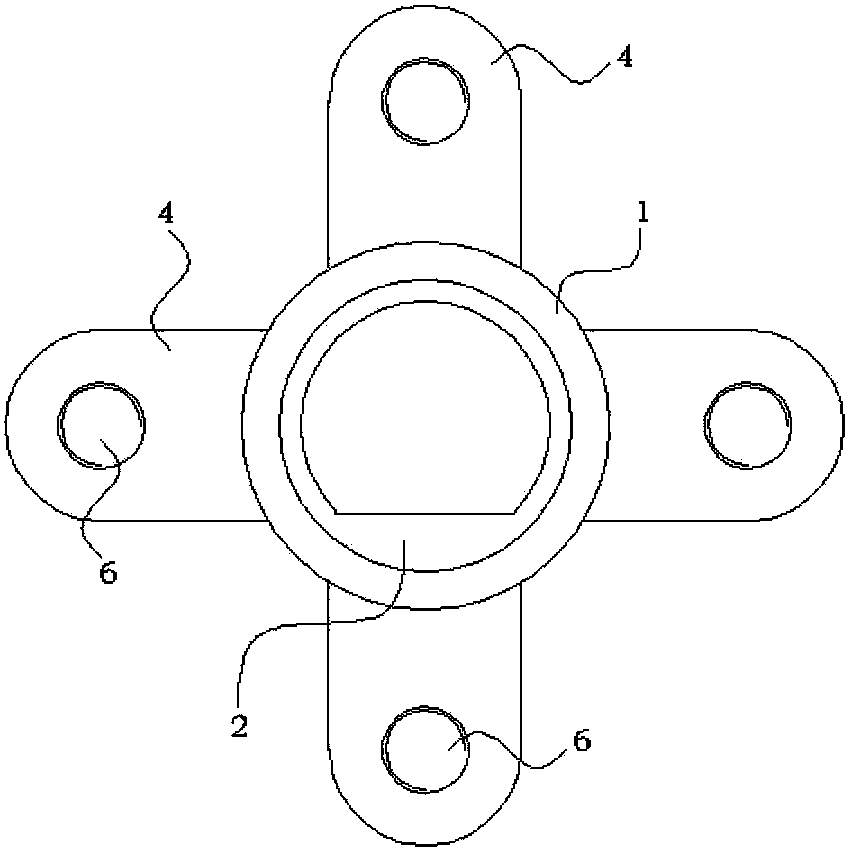

Drill stem oil pipe or sucker rod marking method

InactiveCN1676864AEasy to useKnow exactly when to use itDrilling rodsDrilling casingsSucker rodDrill pipe

This invention involves the marking technology, one kind of drill rod oil tube or the oil extraction rod marking method. This invention is equipped with the ring structure the carrier, carries the product information the code content, then sets it into oil tube or tube-pole connect center; states the ring structure carrier and connect between in the closer way; States the ring structure carrier with tube-pole between which remains a gap. This invention can realize the marking time which is long, the cost is low, and may work under the adverse circumstance goal.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

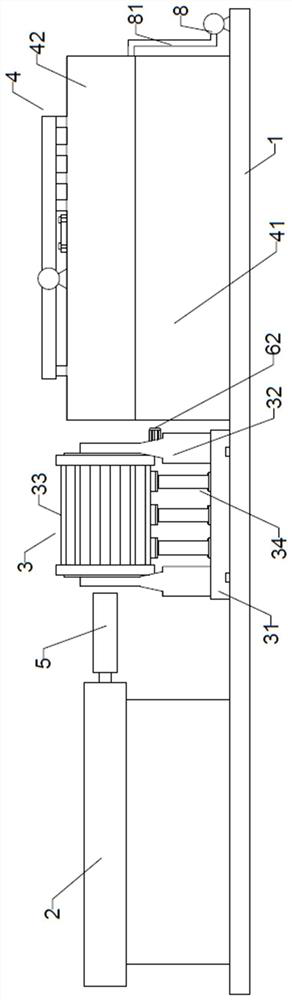

Aluminum material extruding machine with automatic material conveying structure and using method of aluminum material extruding machine

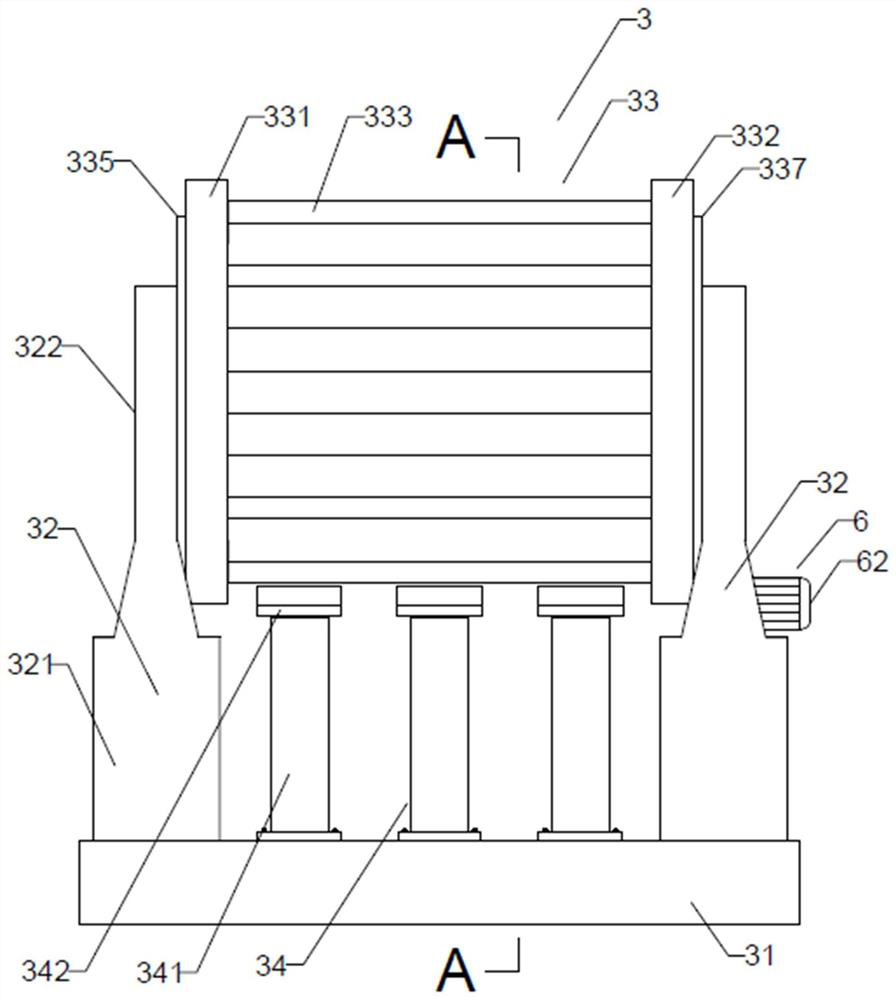

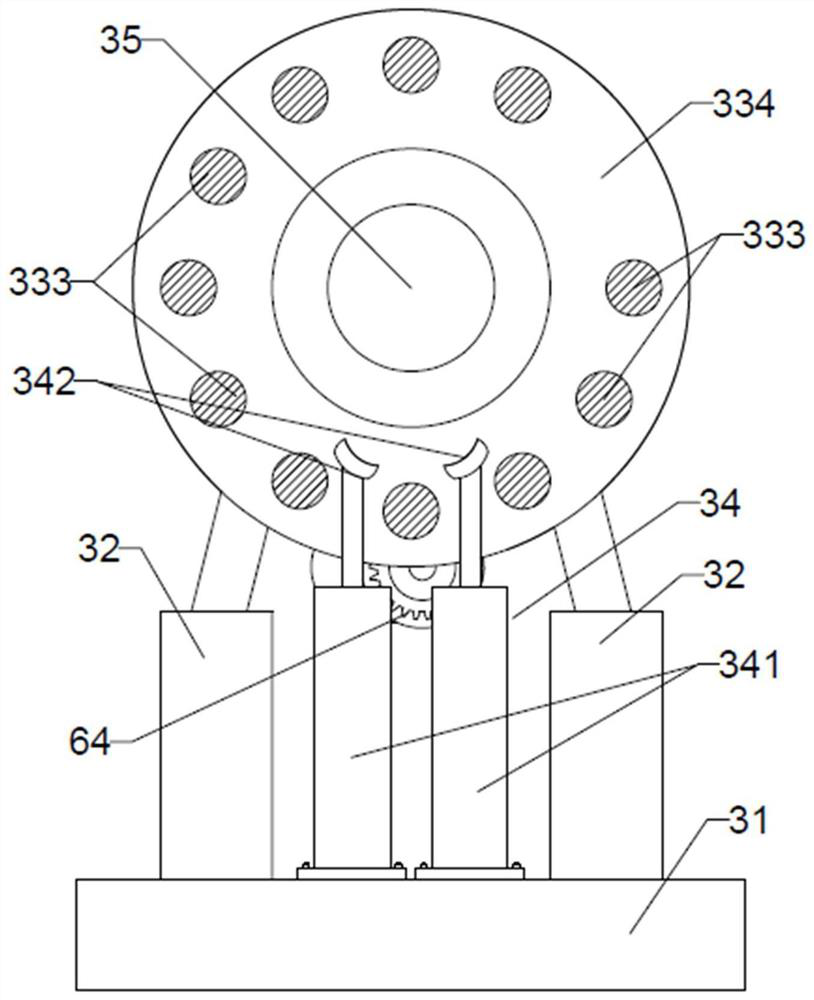

The invention discloses an aluminum material extruding machine with an automatic material conveying structure. The aluminum material extruding machine with the automatic material conveying structure comprises a workbench, an extruding hydraulic cylinder, a material conveying mechanism and an extruding machine body, the extruding hydraulic cylinder and the extruding machine body are fixedly arranged on the workbench, and an extruding column is arranged at the end, close to the extruding machine body, of the extruding hydraulic cylinder; the material conveying mechanism is movably arranged on the workbench and moves in the direction perpendicular to the connecting line of the extruding hydraulic cylinder and the extruding machine body; and the material conveying mechanism comprises a movable base, a set of feeding supports, a feeding rolling cage and a set of lifting mechanisms. When the aluminum material extruding machine with the automatic material conveying structure is used, an aluminum bar is placed in the feeding rolling cage and conveyed to the position between the extruding hydraulic cylinder and the extruding machine body, the aluminum bar is lifted up through the lifting mechanism, the extruding hydraulic cylinder drives the extruding column to push the aluminum bar into the extruding machine body to be extruded, in the material conveying process, the aluminum bar is placed in the semi-closed feeding rolling cage and cannot fall off to cause accidents, safety is greatly improved, and meanwhile product quality is guaranteed.

Owner:JIANGSU WEIYE ALUMINUM MATERIAL

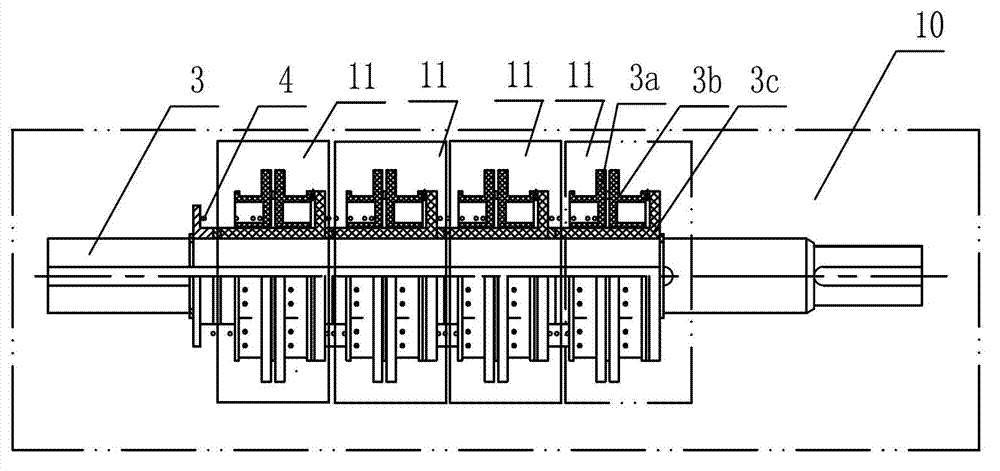

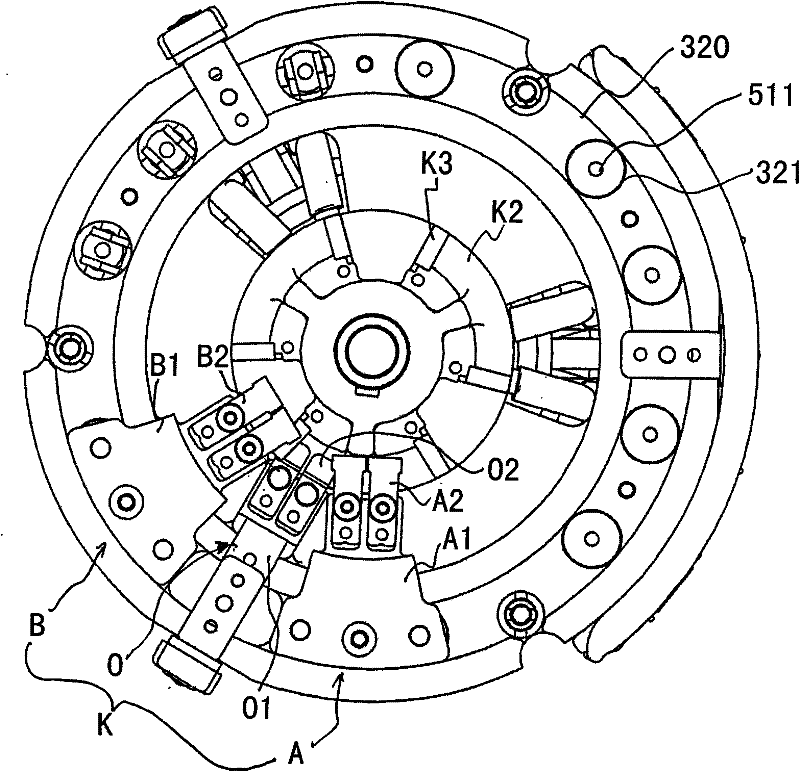

Adjustable cam controller with mechanical limiting function

The invention relates to an adjustable cam controller with a mechanical limiting function. The adjustable cam controller comprises a camshaft and a cam component which is arranged on the camshaft, wherein the cam component comprises a shaft sleeve, and an outer cam piece and an inner cam piece which are sleeved on the shaft sleeve; two side end faces of the inner cam piece are provided with gear rings; one side end face of the outer cam piece is provided with a gear ring; a side end face of the shaft sleeve is provided with a gear ring; the gear ring on one side end face of the inner cam piece is meshed with the gear ring on the end face of the shaft sleeve; the gear ring on the other side end face of the inner cam piece is meshed with the gear ring on the end face of the outer cam piece; the inner sides of the gear rings on the two end faces of the inner cam piece are provided with a first limiting device and a second limiting device; the inner side of the gear ring on the end face of the outer cam piece is provided with a third limiting device which can rotate in a range of less than 360 degrees relative to the first limiting device; and the inner side of the gear ring on the end face of the shaft sleeve is provided with a fourth limiting device which can rotate in a range of less than 360 degrees relative to the second limiting device. The inner and outer cam pieces only can be adjusted in the specified angle range.

Owner:WUXI TUOFA AUTOMATIC CONTROL EQUIP

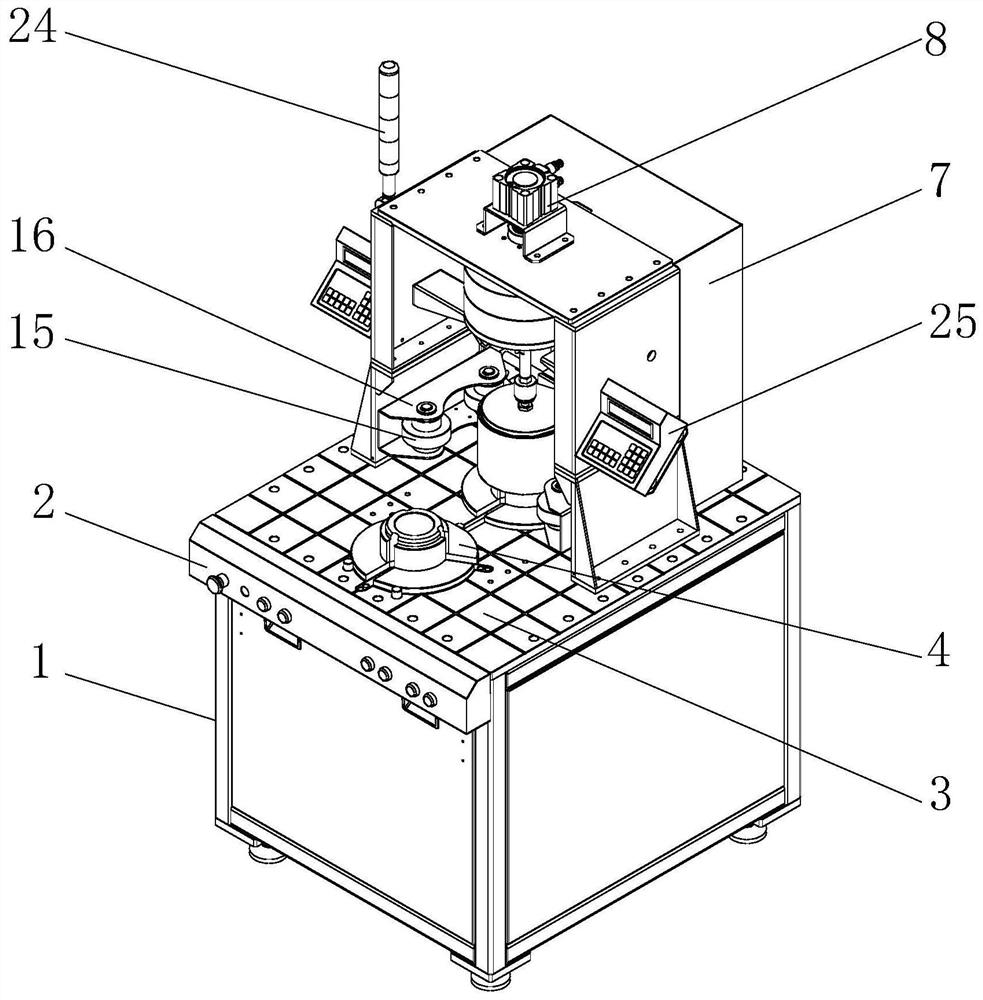

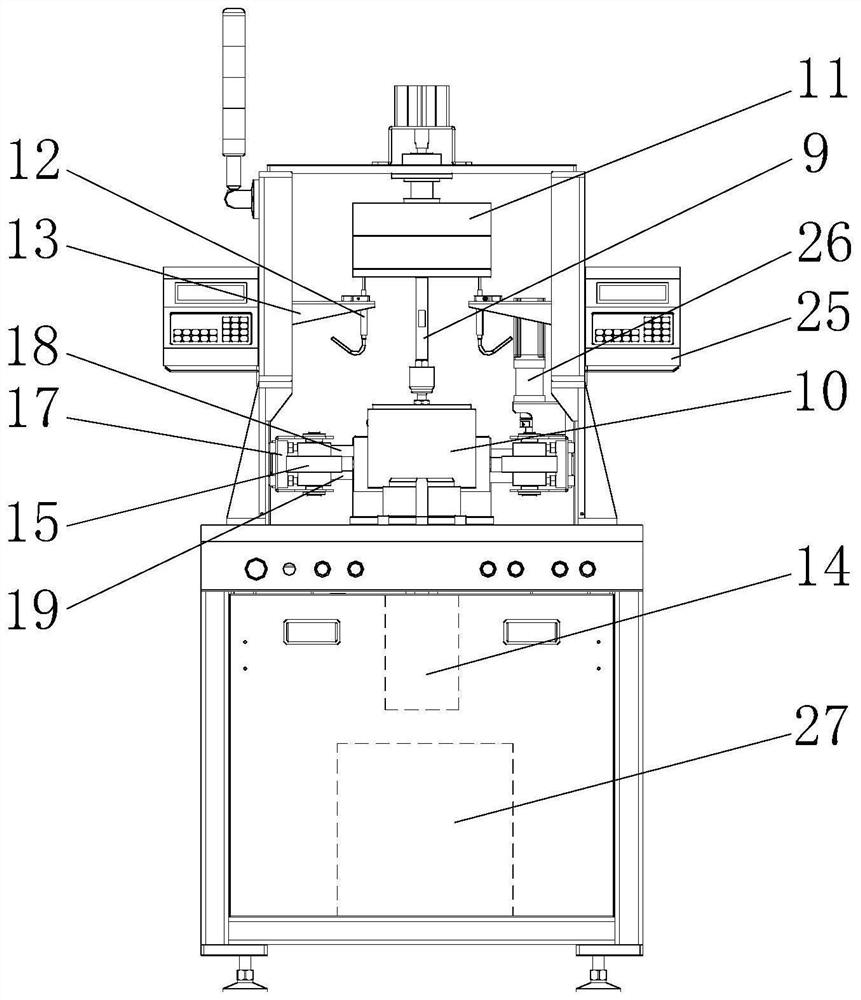

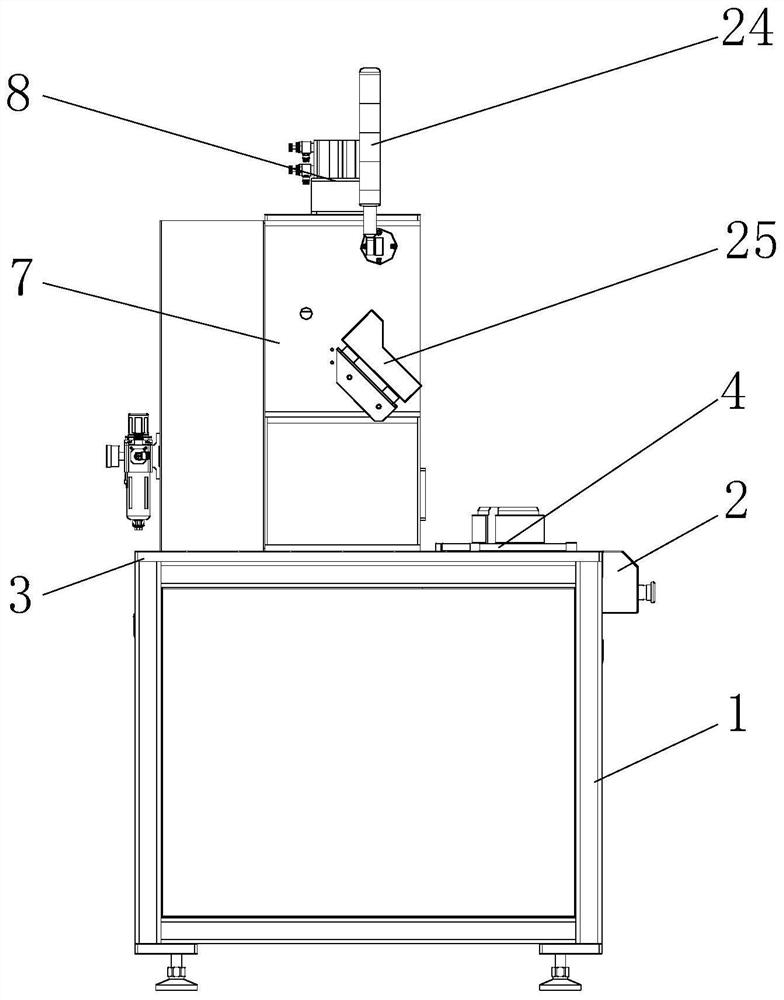

Bearing clearance measuring machine

InactiveCN112461144APrecise positioningImprove clamping efficiencyUsing optical meansElectric machineryMachine

The invention discloses a bearing clearance measuring machine which comprises a machine body. An operation panel is arranged at the upper end of the front surface of the machine body, a working tableis arranged at the top of the machine body, a sliding groove is formed in the working table, a measuring base is arranged in the sliding groove in a sliding mode, and a limiting column is fixed to theportion, at the outer end of the sliding groove, of the working table. A rack is fixed to the top of the working table, an air cylinder is vertically fixed to the top of the rack, a piston rod in theair cylinder is fixedly connected with one end of a connecting rod, and the other end of the connecting rod is fixedly connected with a balance weight load. By arranging a clamping wheel, a clampingwheel frame body, a lead screw nut, an upper lead screw, a lower lead screw, a double-end clamping motor, a guide column and a grating ruler, automatic centering can be achieved during bearing clamping, positioning is accurate, a symmetrical structure is adopted for driving and loading, the influence of an unbalance loading force on clearance measurement is removed, measurement is performed through the grating ruler, and a measurement result of the whole measurement machine is more accurate.

Owner:柳州市欧博科技有限公司

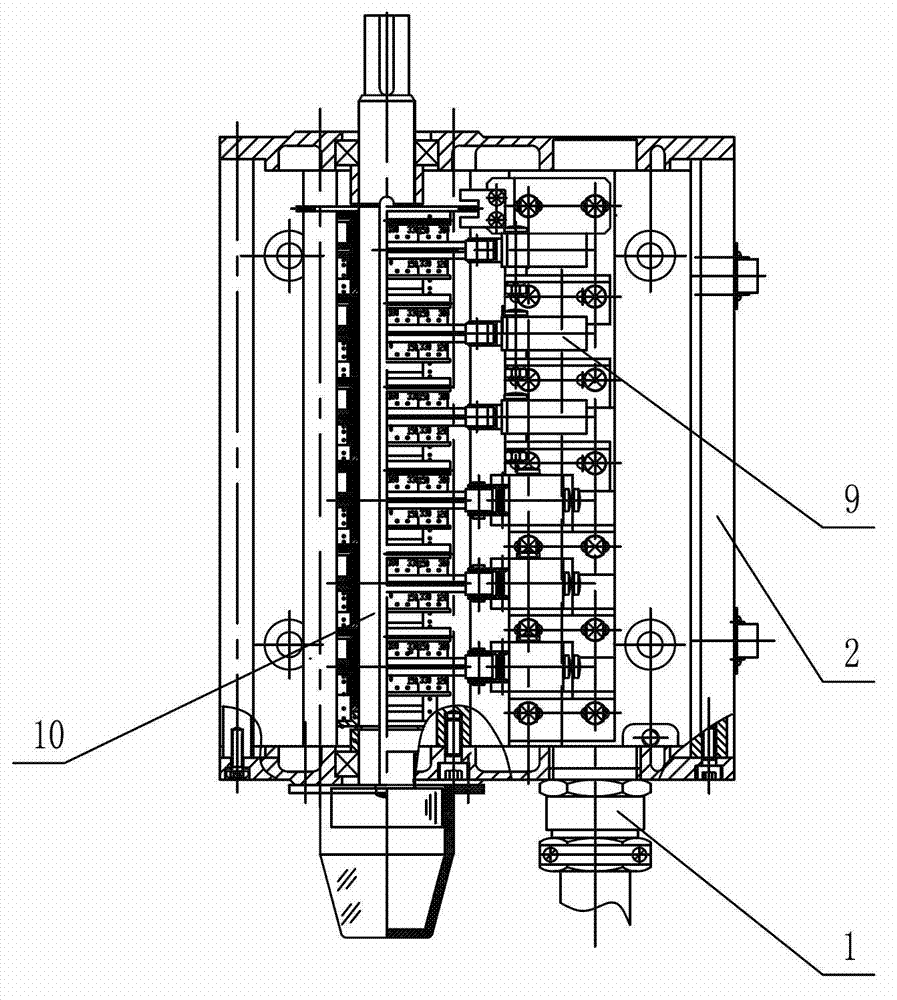

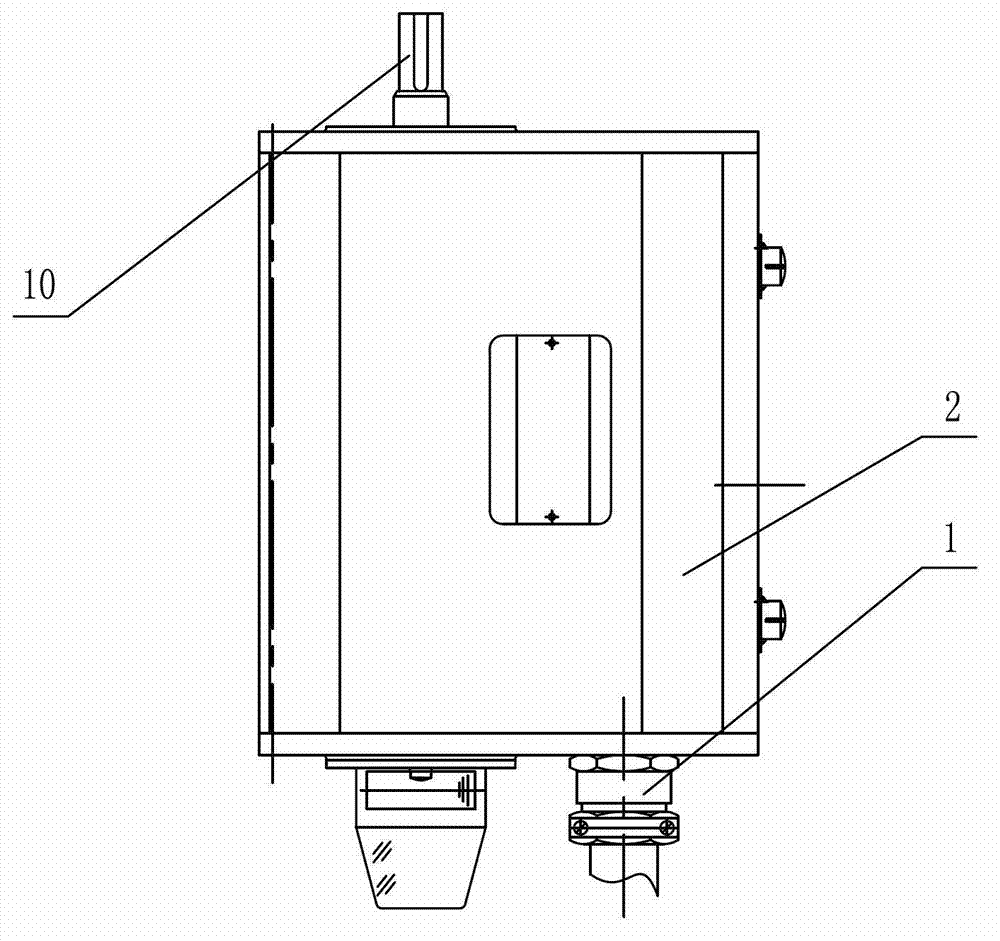

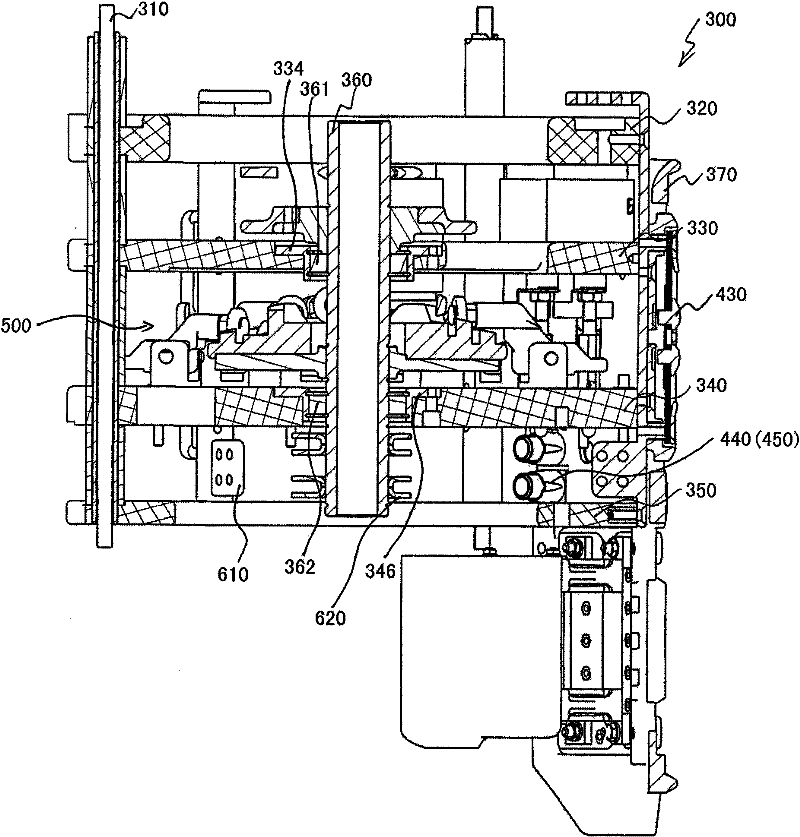

Vacuum vessel switching core used by on-load tap-changer

ActiveCN101651029BEasy to tapImprove electrical lifeVariable inductancesHigh-tension/heavy-dress switchesElectricityTap changer

The invention discloses a vacuum vessel switching core used by an on-load tap-changer, which can mutually exchange with the switching core of the existing M-type on-load tap-changer without changing a switch oil chamber; the vacuum vessel switching core comprises a vacuum vessel transition switching assembly, a neutral point switch and a main through-flow assembly, wherein an upper group and a lower group of triphase cavel-shaped contacts in the main through-flow assembly are combined to put below the vacuum vessel transition switching assembly, and are connected with an original contact by soft connection; the vacuum vessel transition switching assembly is electrically connected with the original neutral point contact by the neutral point switch so as to ensure that the position of the main contact and the position of the neutral point contact do not change. The invention keeps the appearance structure and installation size of the original M-type on-load tap-changer switching core, can conveniently change the original M-type on-load tap-changer switching core on the basis of changing no other components of the original M-type on-load tap-changer, is suitable for replacing and maintaining the existing M-type on-load tap-changer used on site and is suitable for manufacturing new vacuum M-type on-load tap-changers.

Owner:SHANGHAI HUAMING POWER EQUIP CO LTD +1

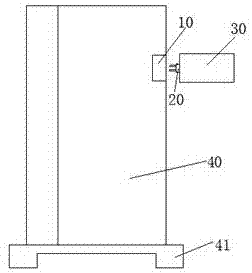

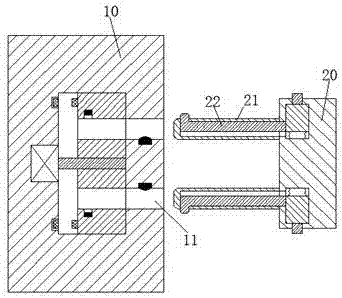

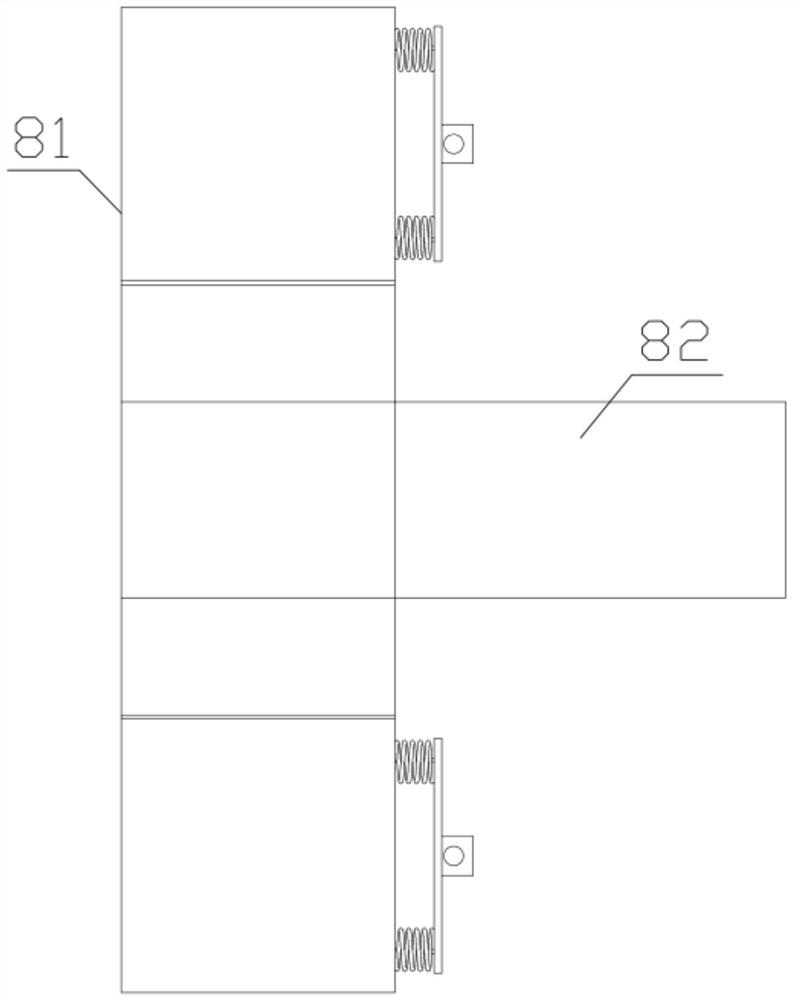

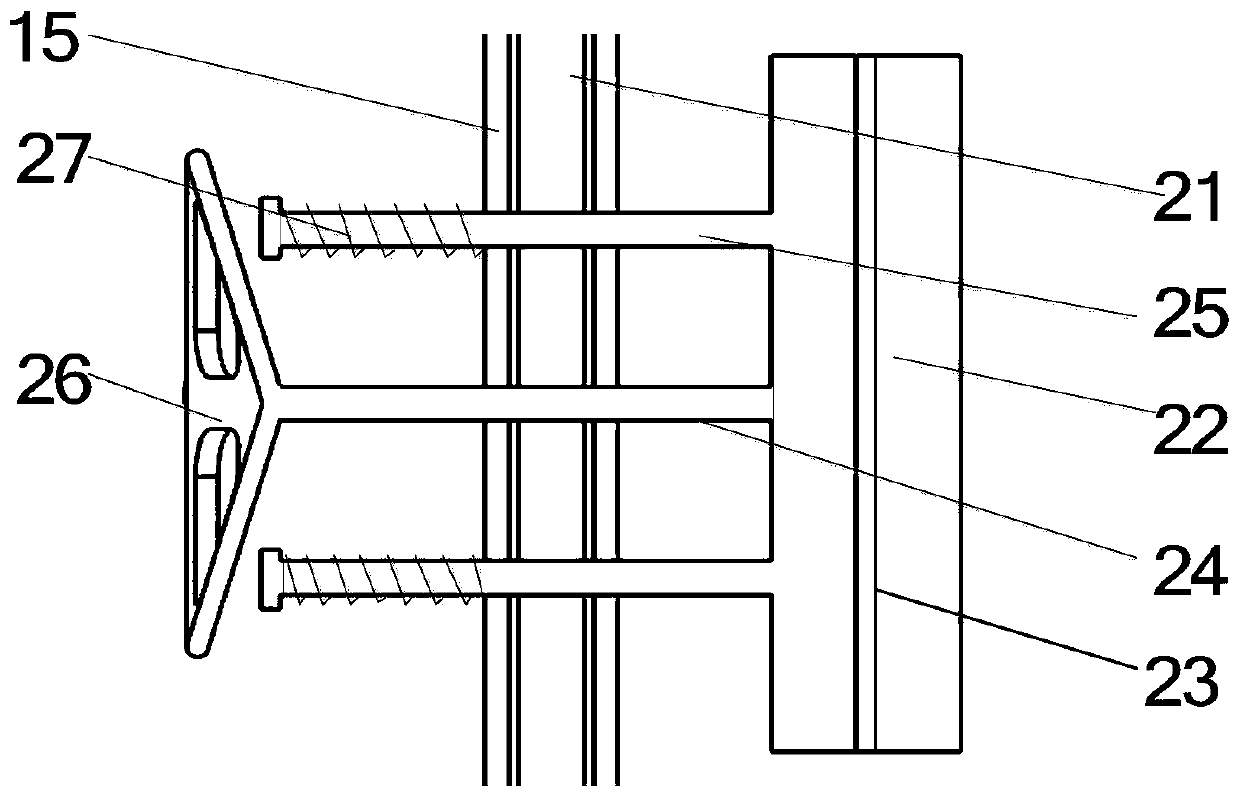

Plug mechanism for electrical appliance electrification

InactiveCN108233087AWon't cause an accidentAchieve electrificationTwo-part coupling devicesLive contact access preventionEngineeringBlock match

The invention relates to a plug mechanism for electrical appliance electrification. The plug mechanism for electrical appliance electrification comprises a comprises a bayonet socket and a connectingplug; a sliding connection cavity is formed in the bayonet socket; plug grooves communicated with the outside are formed in the right end wall of the sliding connection cavity in a longitudinal symmetrical mode; a sliding connection frame is arranged in the sliding connection cavity in a left-and-right sliding mode; left-and-right communicated through grooves are formed in the sliding connection frame in a longitudinal symmetrical mode; a threaded rod is mounted in the sliding connection frame in a threaded fit mode; the right end of the threaded rod is rotatably mounted in the right end wallof the sliding connection cavity; the left end of the threaded rod is matched and connected with a motor fixedly mounted in the left end wall of the sliding connection cavity; first grooves are symmetrically formed in the left end wall of the sliding connection cavity in a longitudinal symmetrical mode; power supply blocks connected with commercial powder are fixedly mounted in the first grooves;a plug port is formed in each power supply block, and the opening of the plug port faces the sliding connection frame; conductive blocks matched with the plug ports are arranged on the left end face of the sliding connection frame in a longitudinal symmetrical mode; elastic conductive blocks are fixedly mounted in the inner side end walls of the plug grooves; second grooves are formed in the outerside end walls of the through grooves; and a contact switch connected with the motor is mounted in each second groove.

Owner:韦敬生

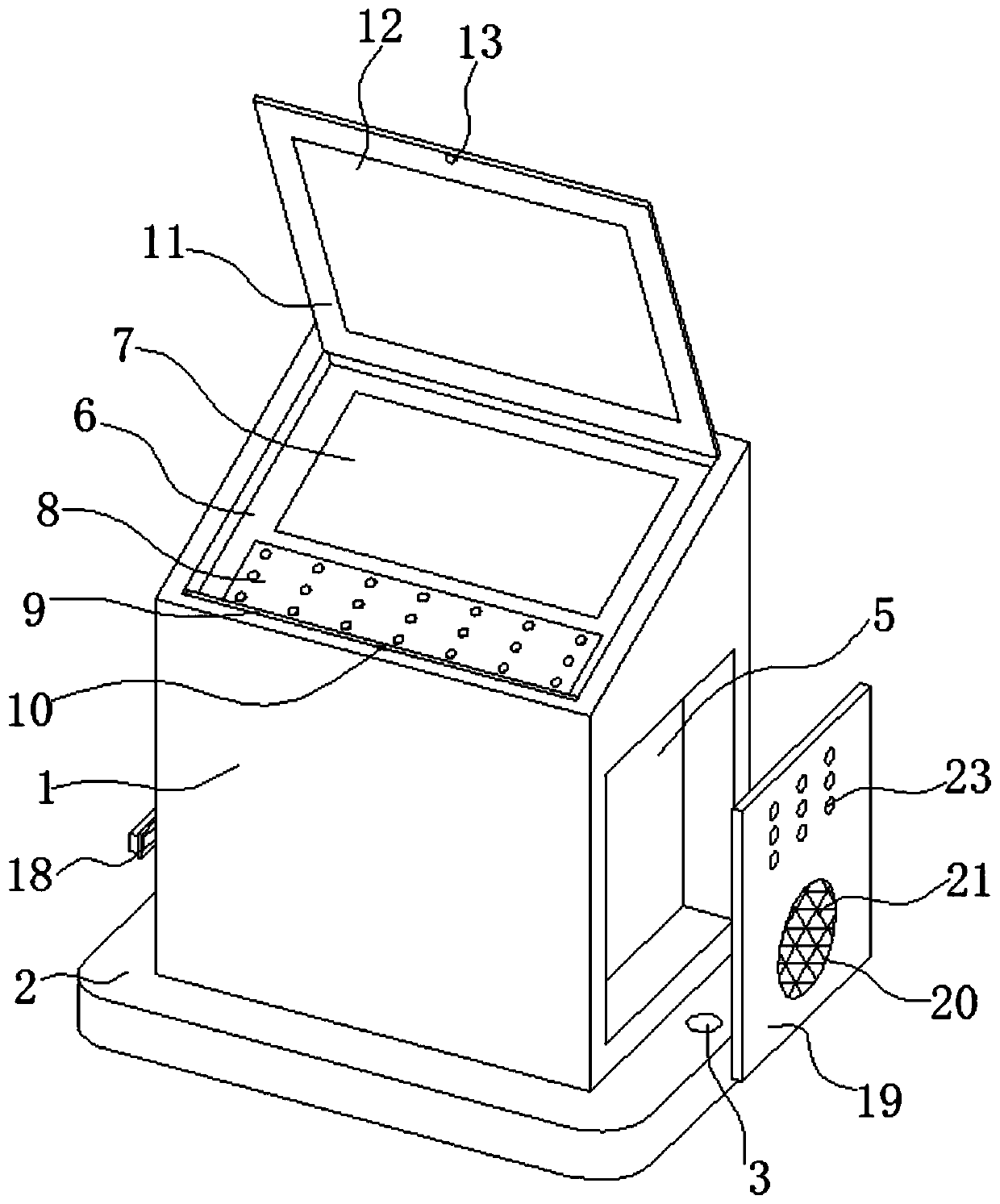

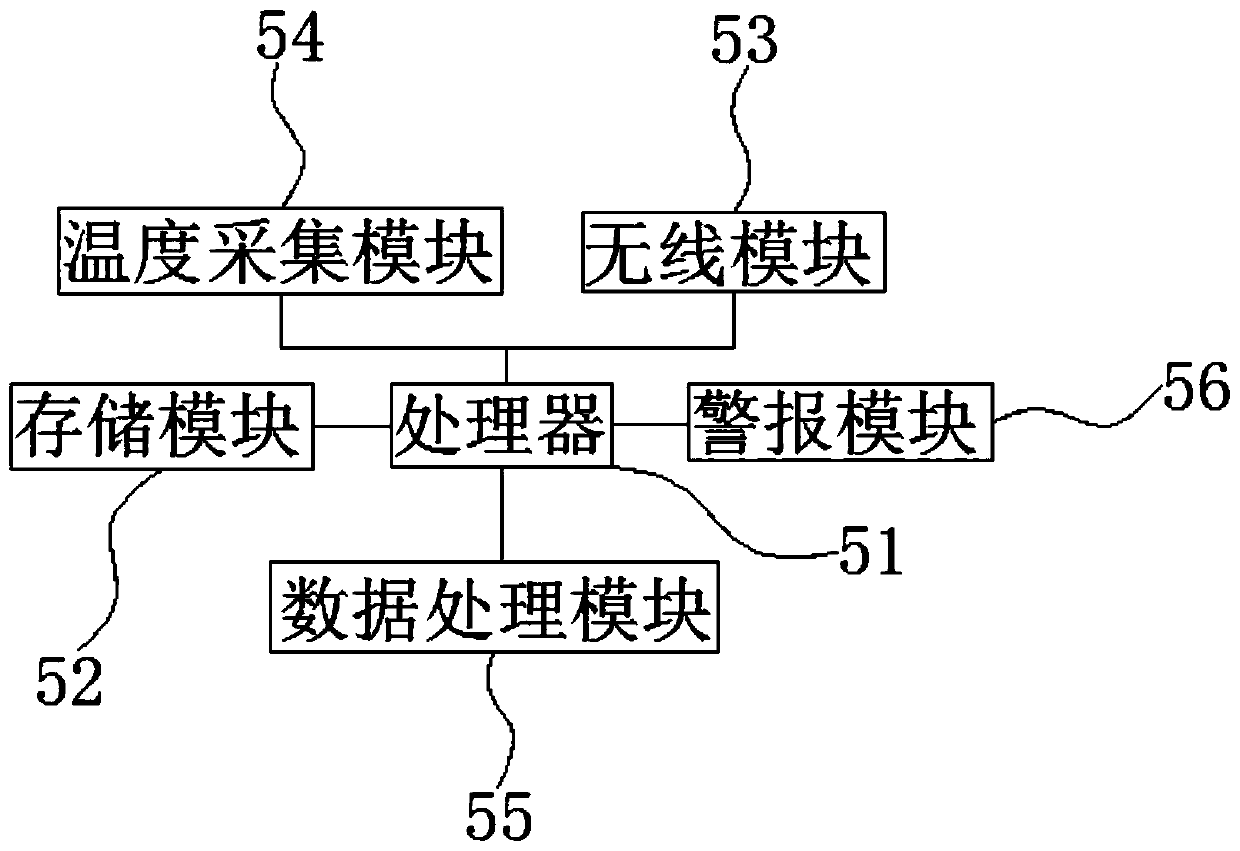

Conventional instrument data intelligent acquisition and monitoring system of traditional transformer substation

PendingCN110944246ANo leakageWon't cause an accidentUtility meters data arrangementsElectrostatic chargesMonitoring systemControl theory

The invention relates to the technical field of substations, and particularly relates to a conventional instrument data intelligent acquisition and monitoring system of a traditional transformer substation. The system includes a shell, the upper end of the shell is connected with a dustproof mechanism; the dustproof mechanism is positioned above a display screen; the shell is fixedly connected with a plurality of discharge tips; a first fixing frame is fixedly connected to the shell. The first fixing frame is positioned outside the discharge tips; the first fixing frame is fixedly connected with an insulating box; the discharge tips are positioned in the insulation box; one side of the shell is fixedly connected with a fixing plate; a through hole is formed in the fixing plate, a dust screen is fixedly connected in the through hole, a heat dissipation mechanism is fixedly connected to the fixing plate, the heat dissipation mechanism is located on one side of the through hole, a plurality of air inlet holes are formed in the fixing plate and located above the through hole, and a dehumidification mechanism is fixedly connected to the fixing plate and located on one side of the air inlet holes. Charges are released in a point discharge mode, current leakage is avoided, and accidents are avoided.

Owner:杭州电力设备制造有限公司临安恒信成套电气制造分公司 +1

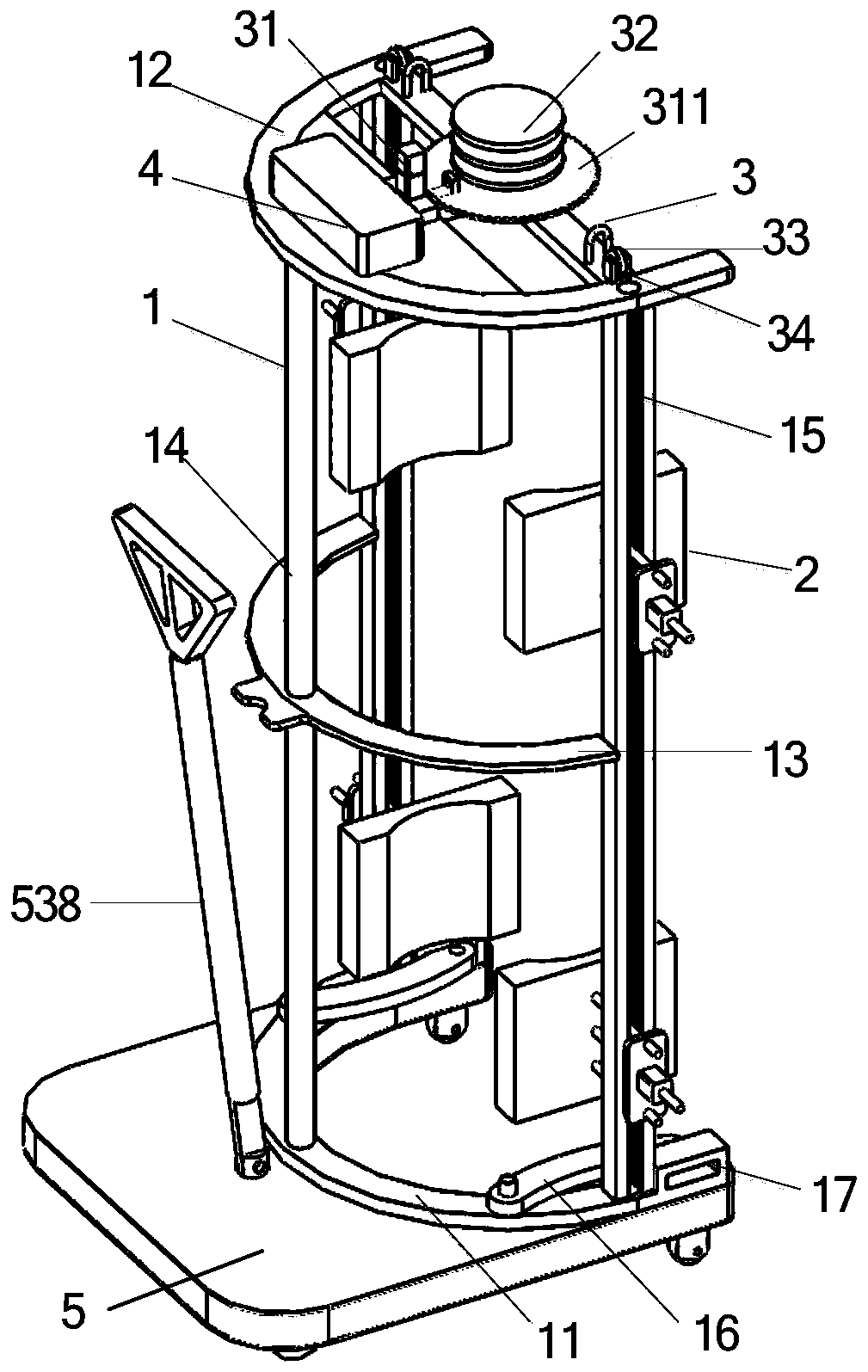

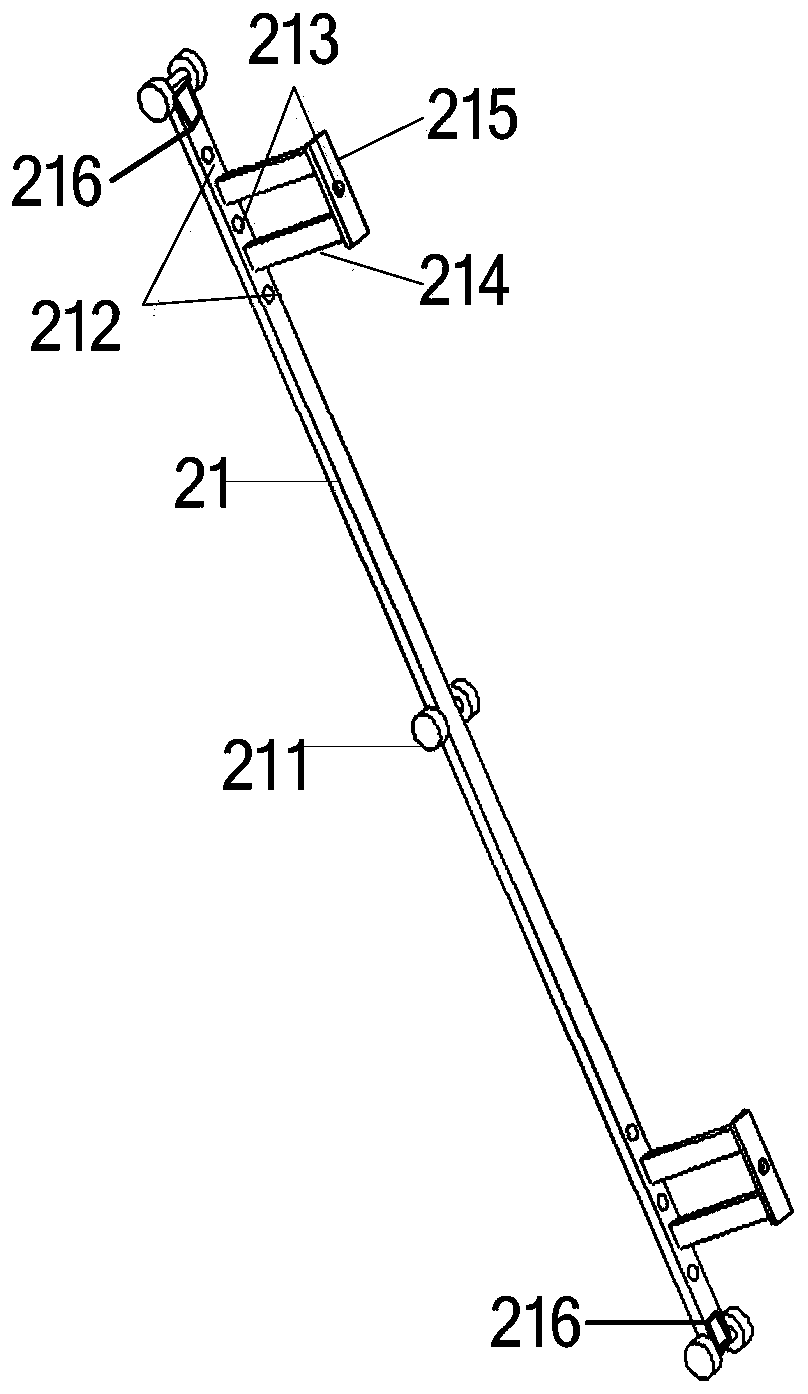

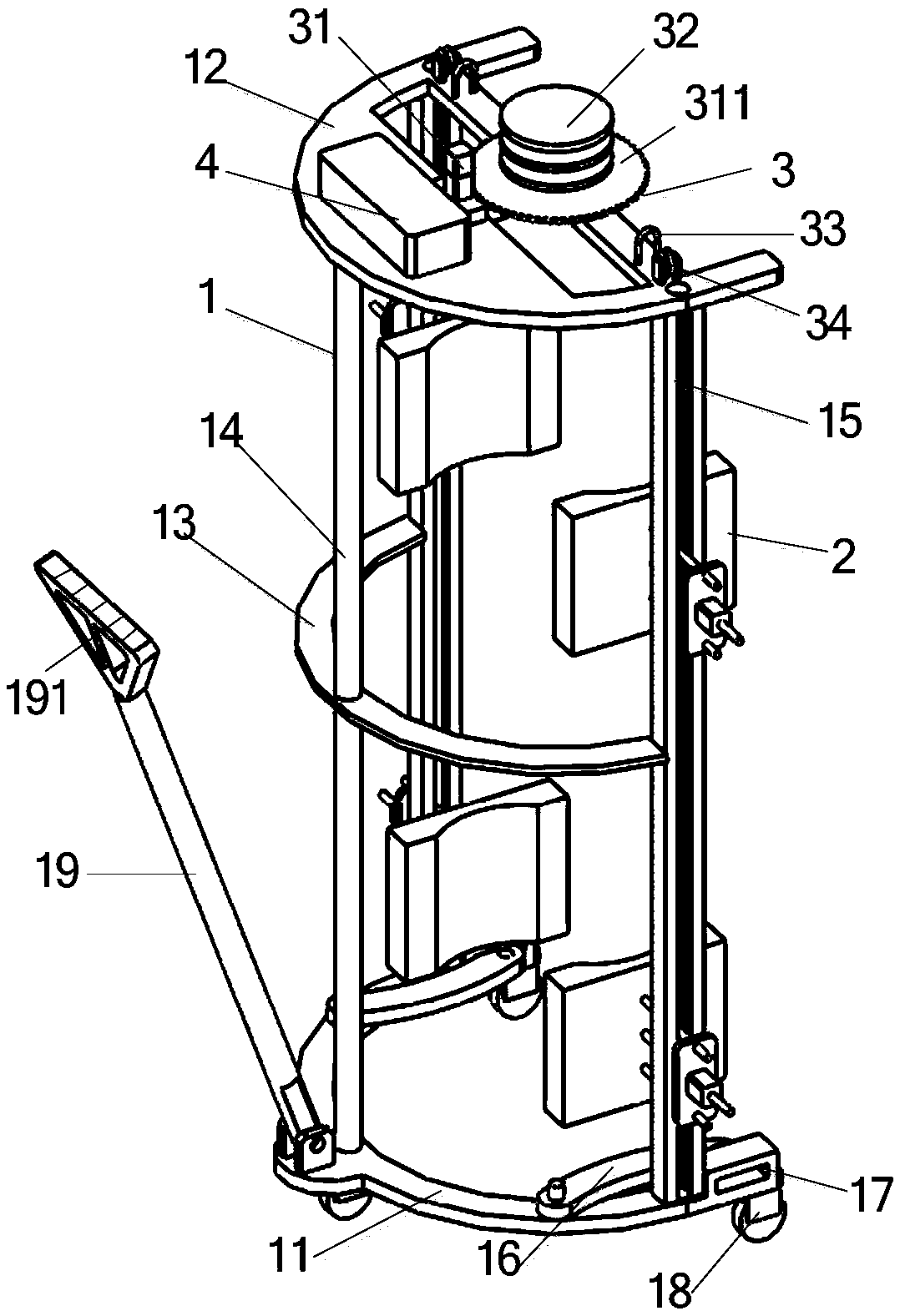

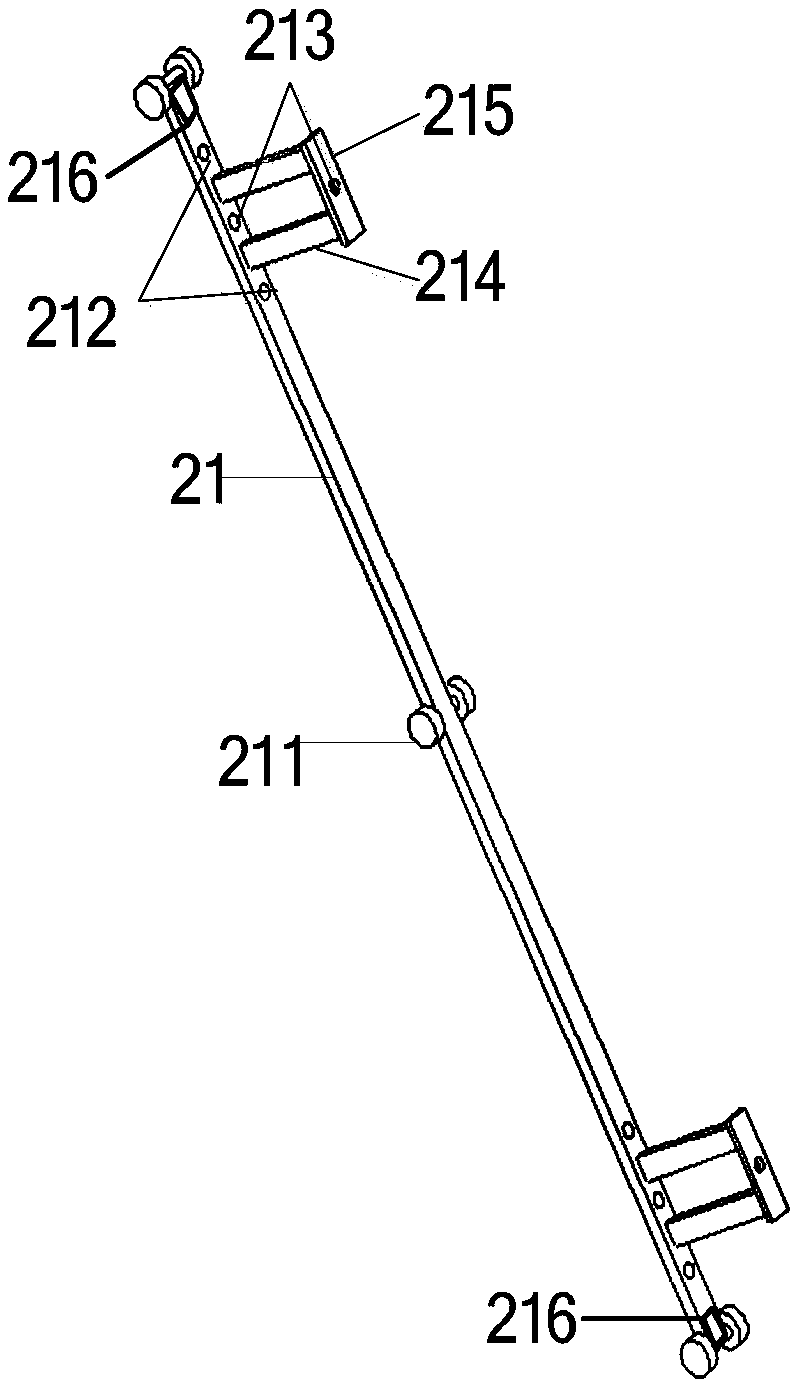

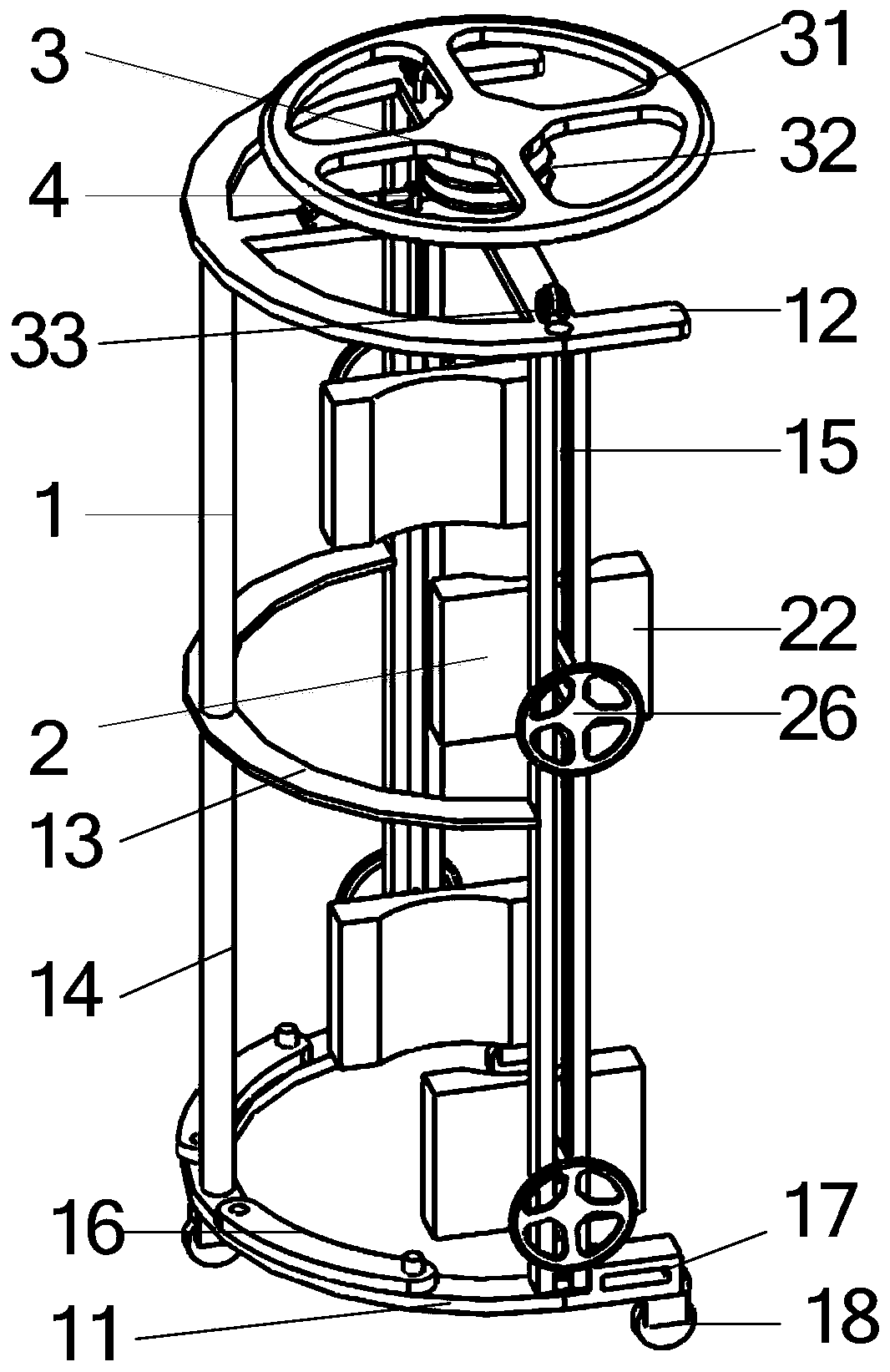

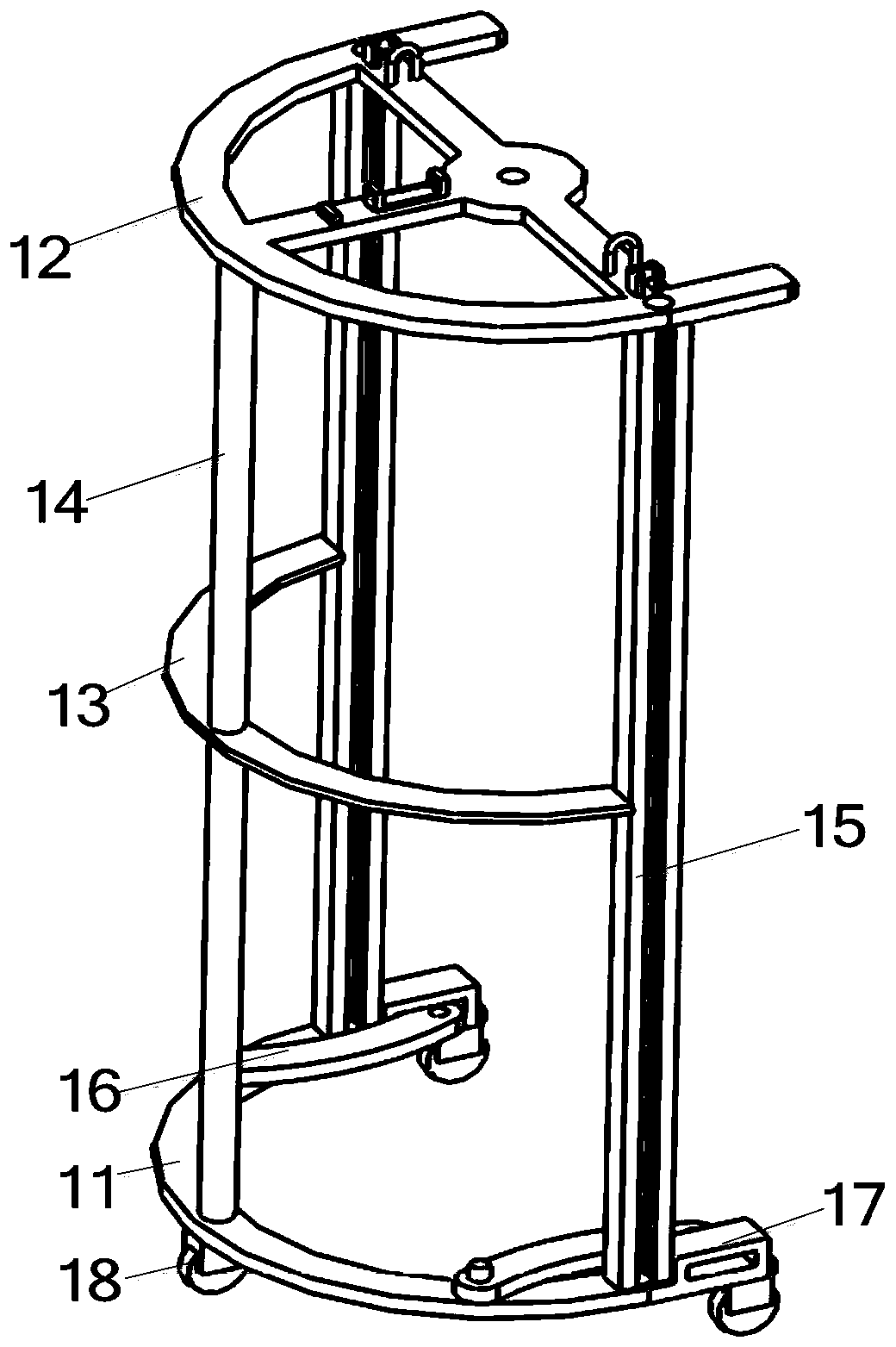

An oil drum handling device with a mobile platform

ActiveCN107416000BReduce labor intensityAvoid collision damageHand carts with multiple axesSelf lockingPulley

The invention provides an oil drum carrying device with a movement platform, and belongs to the field of oil drum carrying equipment. The oil drum carrying device comprises a frame, a clamping part, a pulling and rising part and the movement platform; the frame comprises a semi-arc-shaped bottom plate arranged at the lower portion, a top plate is arranged over the bottom plate, a stand column and guide columns are arranged between the bottom plate and the top plate, the stand column is arranged in the middle portion of the bottom plate, and the guide columns are arranged at the two ends of the bottom plate and are each provided with a guide rail; wheels with the self-locking function are arranged at the middle portion and the two ends of the lower end face of the bottom plate; the clamping part comprises movable pieces arranged on the guide rails, and the movable pieces are installed on the guide rails through wheel sets and slide along the guide rails; the pulling and rising part comprises a first driving device, a wire coil, a fixed pulley, a limiting ring and an upper pull rope; and the movement platform comprises a shell, a second drive device and a steering device. The problems that human cost for oil drum carrying is high, and safety performance cannot be achieved are solved.

Owner:韩再满

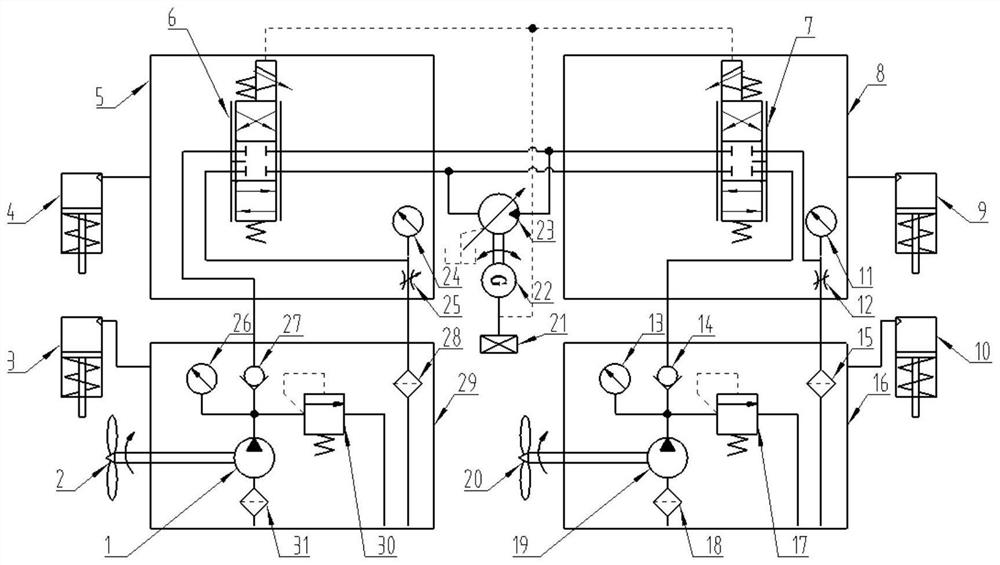

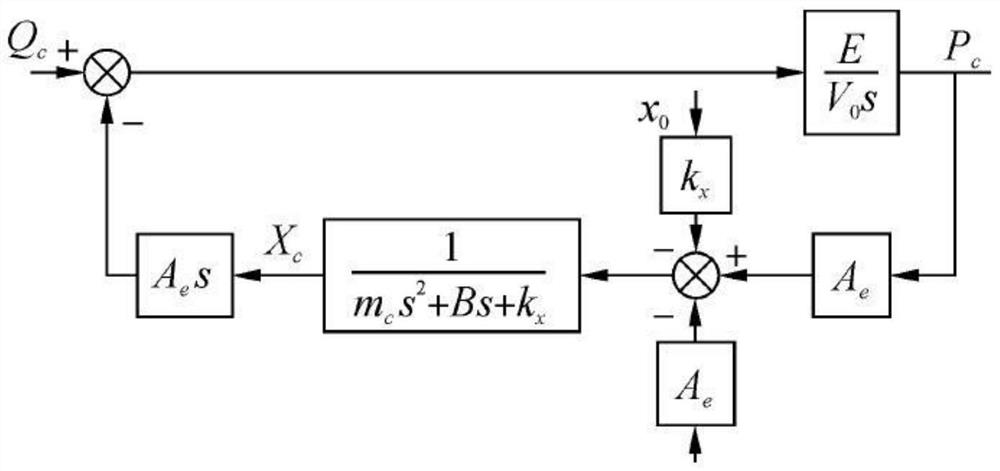

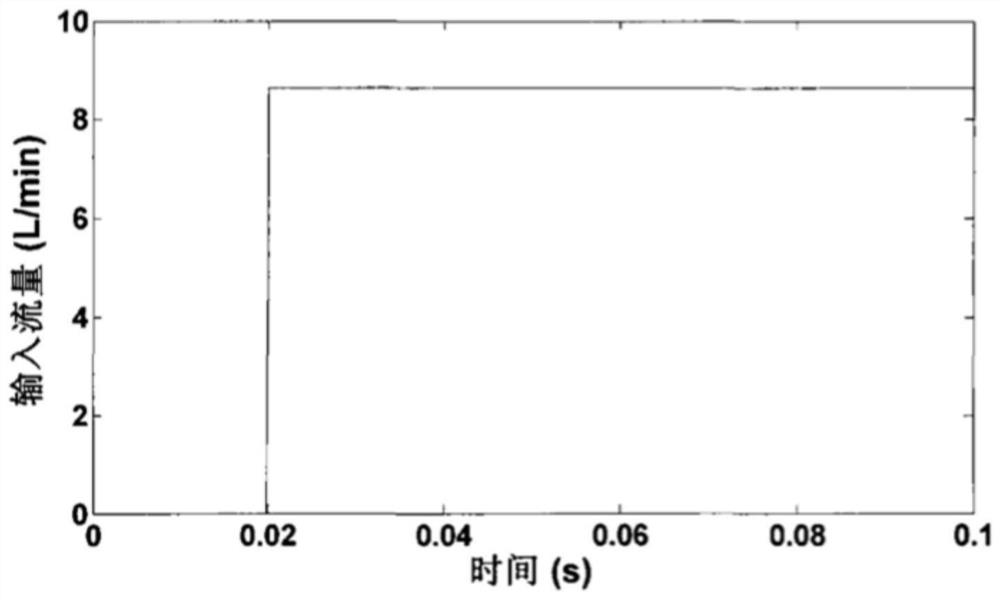

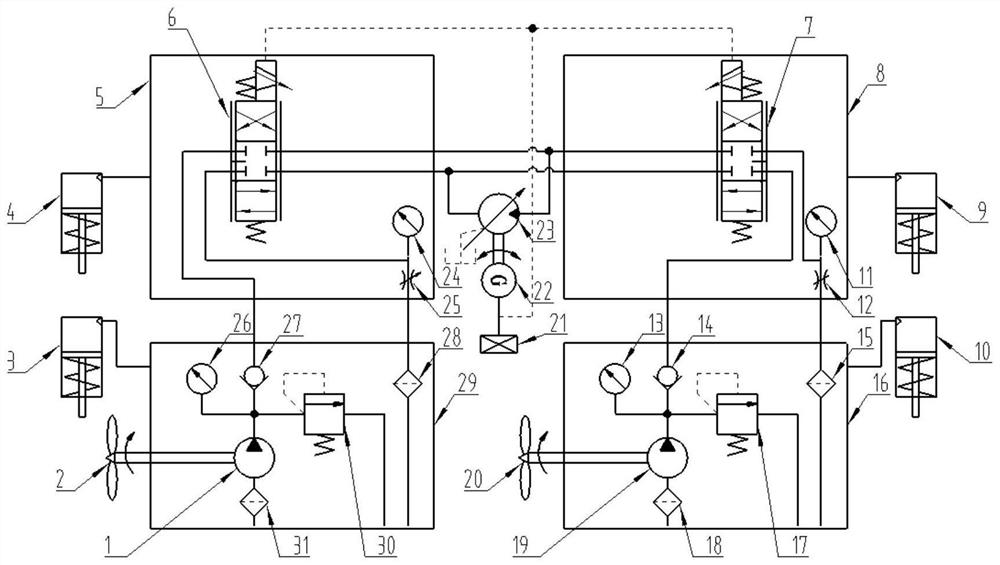

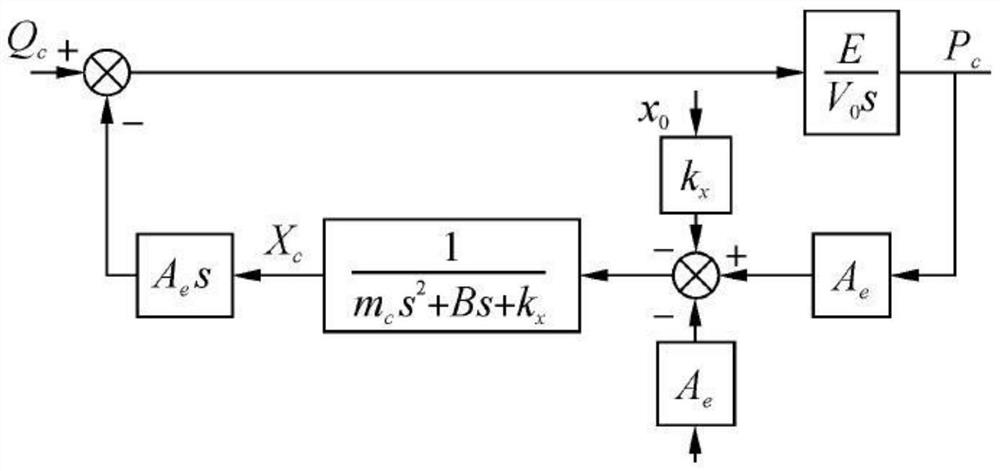

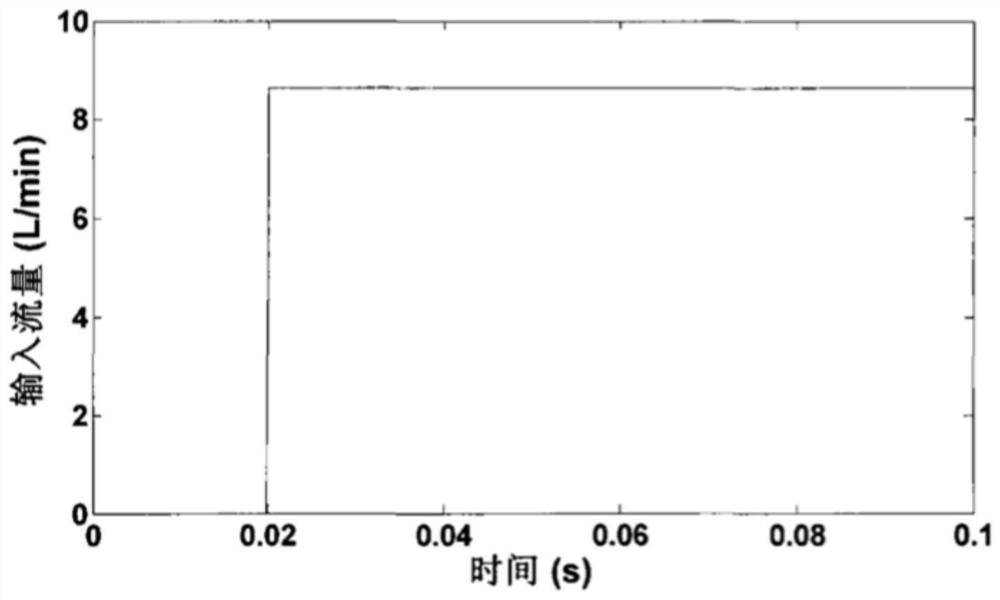

Hydraulic power generation self-adaptive dynamic pressure compensation system of deep sea ocean current energy water turbine

ActiveCN112879211APower generation is green and cleanChange direction of motionMachines/enginesSafety/regulatory devicesWater turbineStream flow

The invention discloses a hydraulic power generation self-adaptive dynamic pressure compensation system of a deep sea ocean current energy water turbine. An ocean current energy water turbine energy capturing subsystem is adopted to efficiently capture deep sea low-flow-speed ocean current energy to obtain ocean current kinetic energy so as to realize rotation of a hydraulic pump output shaft of a hydraulic control subsystem to generate hydraulic system pressure; an electromagnetic reversing control subsystem realizes pressure flow conversion in different directions, an external pressure compensation subsystem realizes pressure balance compensation between deep sea water pressure and a hydraulic system, a hydraulic motor subsystem drives a power generation subsystem to supply power to a load subsystem, and the power generation subsystem also provides an electric signal to the electromagnetic reversing control subsystem so as to realize direction conversion. According to the hydraulic power generation self-adaptive dynamic pressure compensation system of the deep sea ocean current energy water turbine, rotation of the water turbine can be achieved through a deep-sea low-flow-speed ocean current, the water turbine drives the hydraulic pump control subsystem to generate the hydraulic system pressure, deep-sea high-pressure compensation of the hydraulic system pressure is achieved through the external self-adaptive dynamic pressure compensation subsystem, and the hydraulic system drives a power generator to generate the power.

Owner:XI AN JIAOTONG UNIV

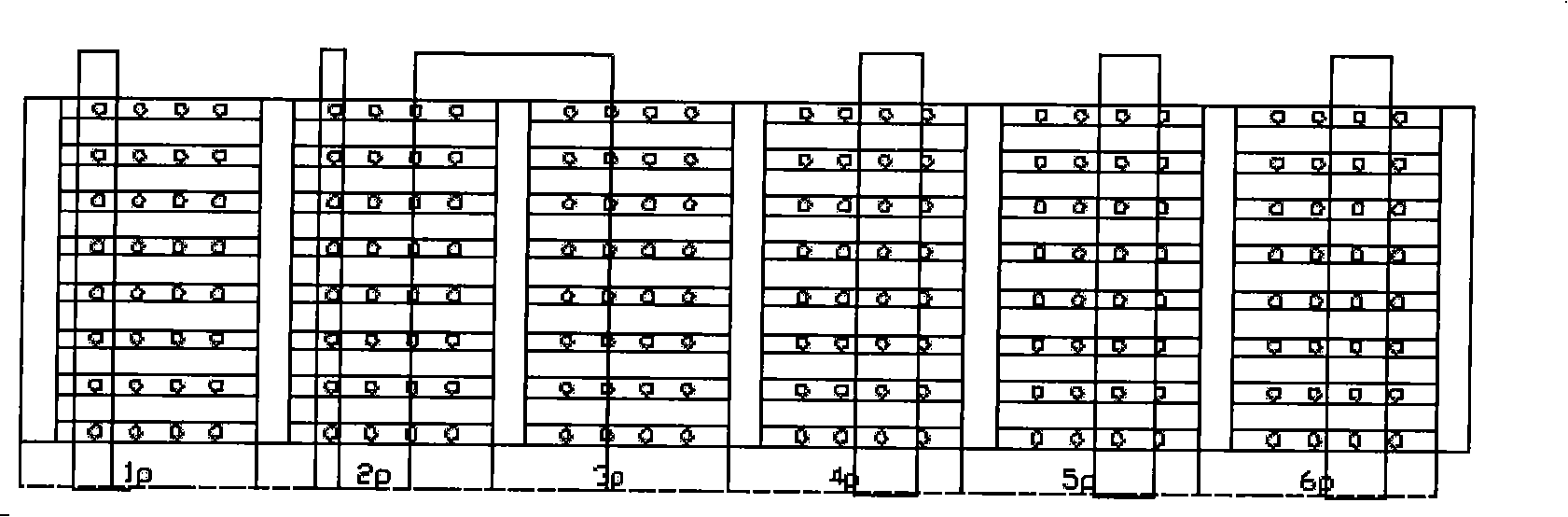

Torrefaction method for pre-baked anode for aluminum

The invention discloses a method for roasting a pre-roasted anode for aluminum and relates to an improved roasting process in the process of producing the pre-roasted anode for the aluminum. The method is characterized in that: in the roasting process, an initial value of 2P is controlled between 330 and 370 DEG C, and an endpoint value of 2P is controlled between 730 and 770 DEG C. The method for roasting the pre-roasted anode for the aluminum can effectively utilize heat energy produced by the combustion of volatile compositions, improve production capacity, save energy, remove the hidden trouble of safety and relieve the difficulty of operation.

Owner:中铝矿业有限公司 +1

Ice and snow fusion method for air power transmission line

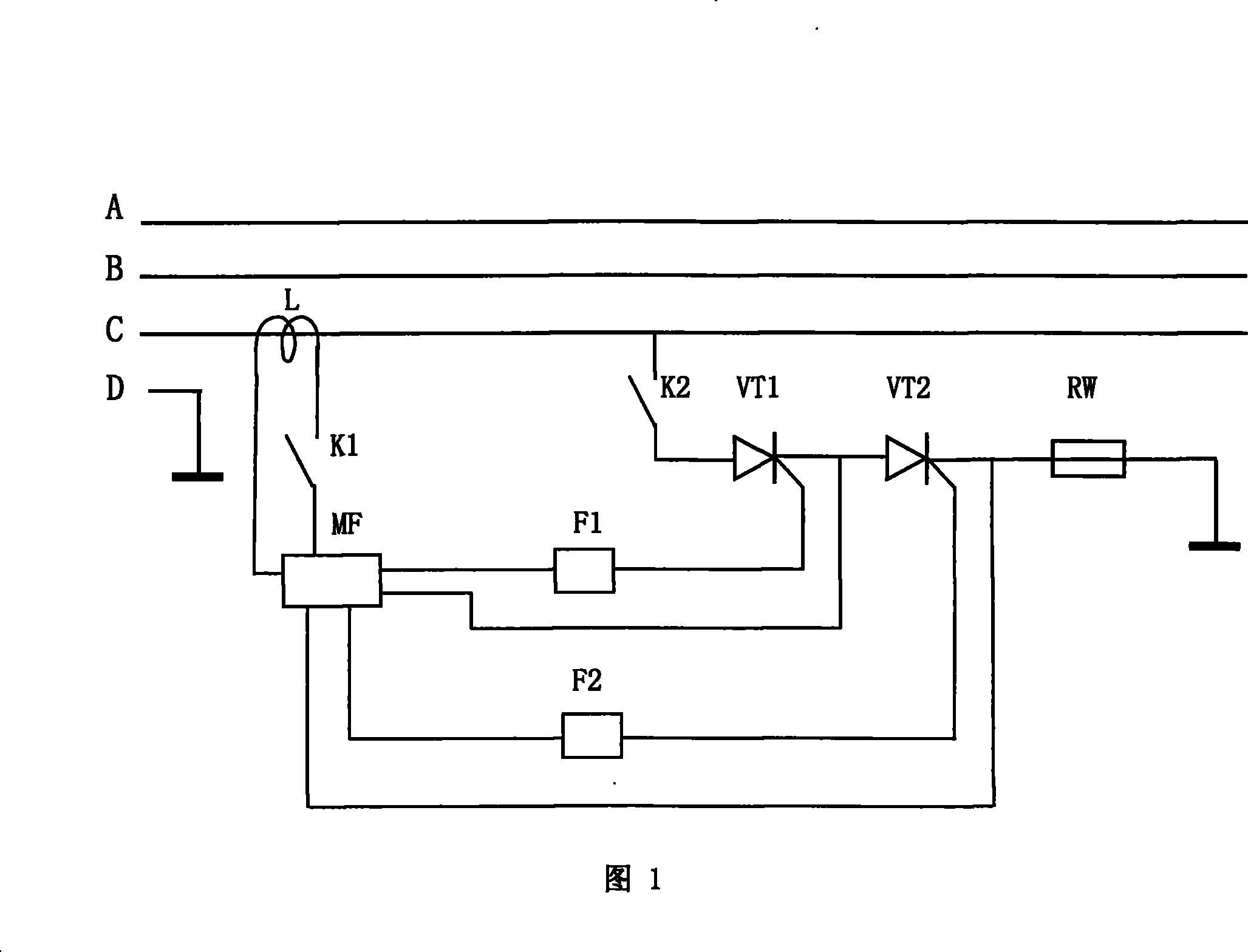

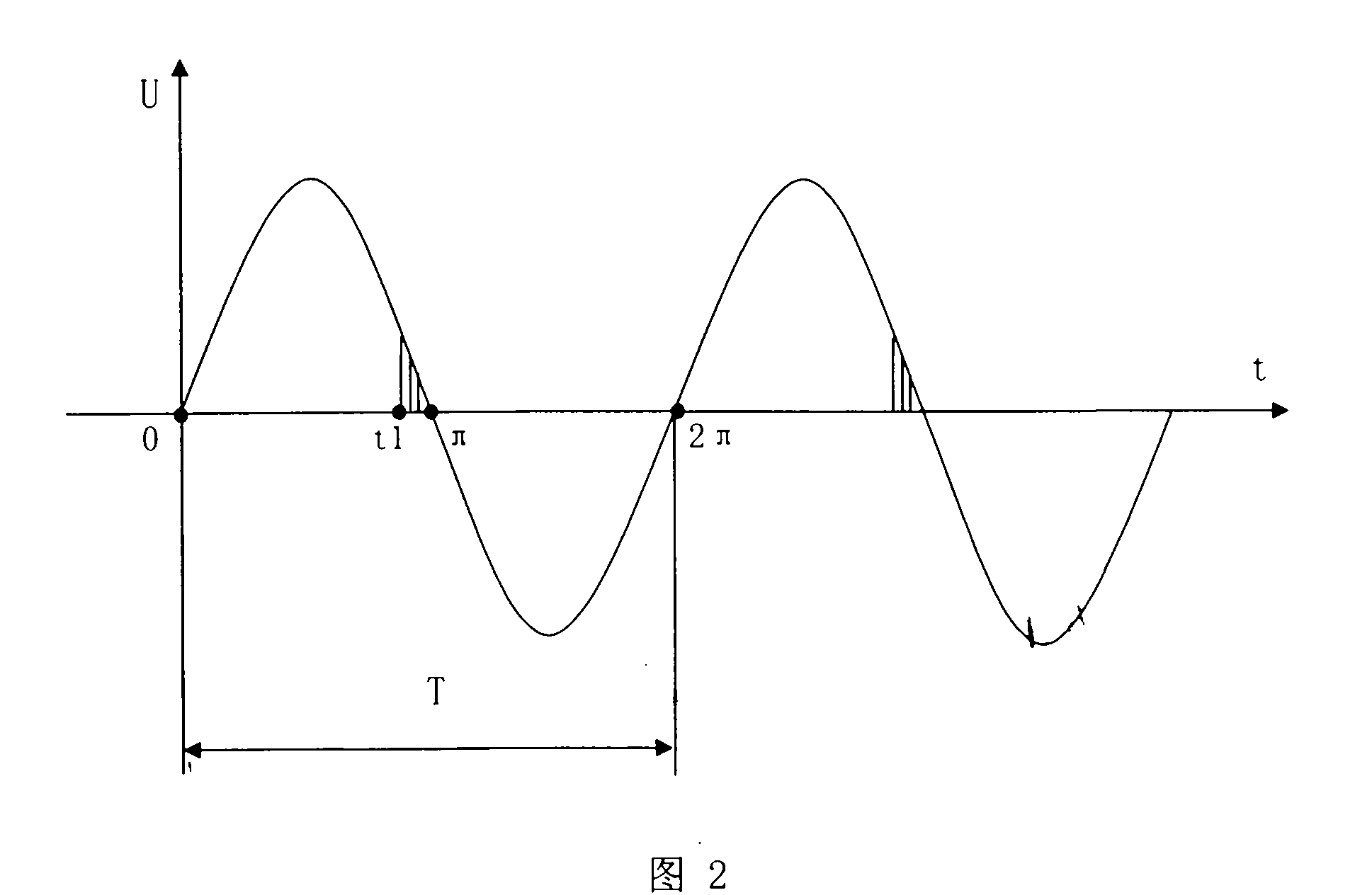

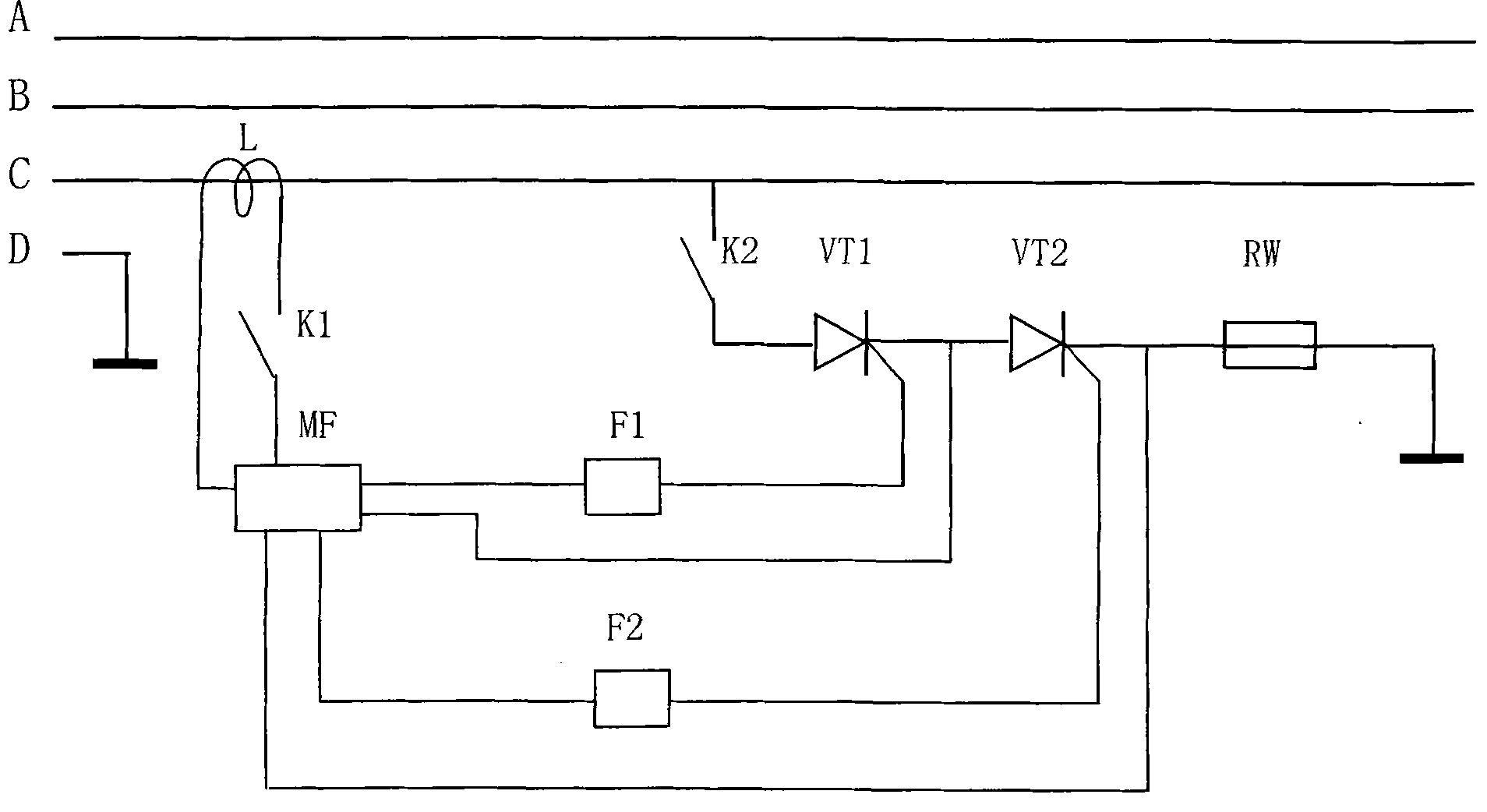

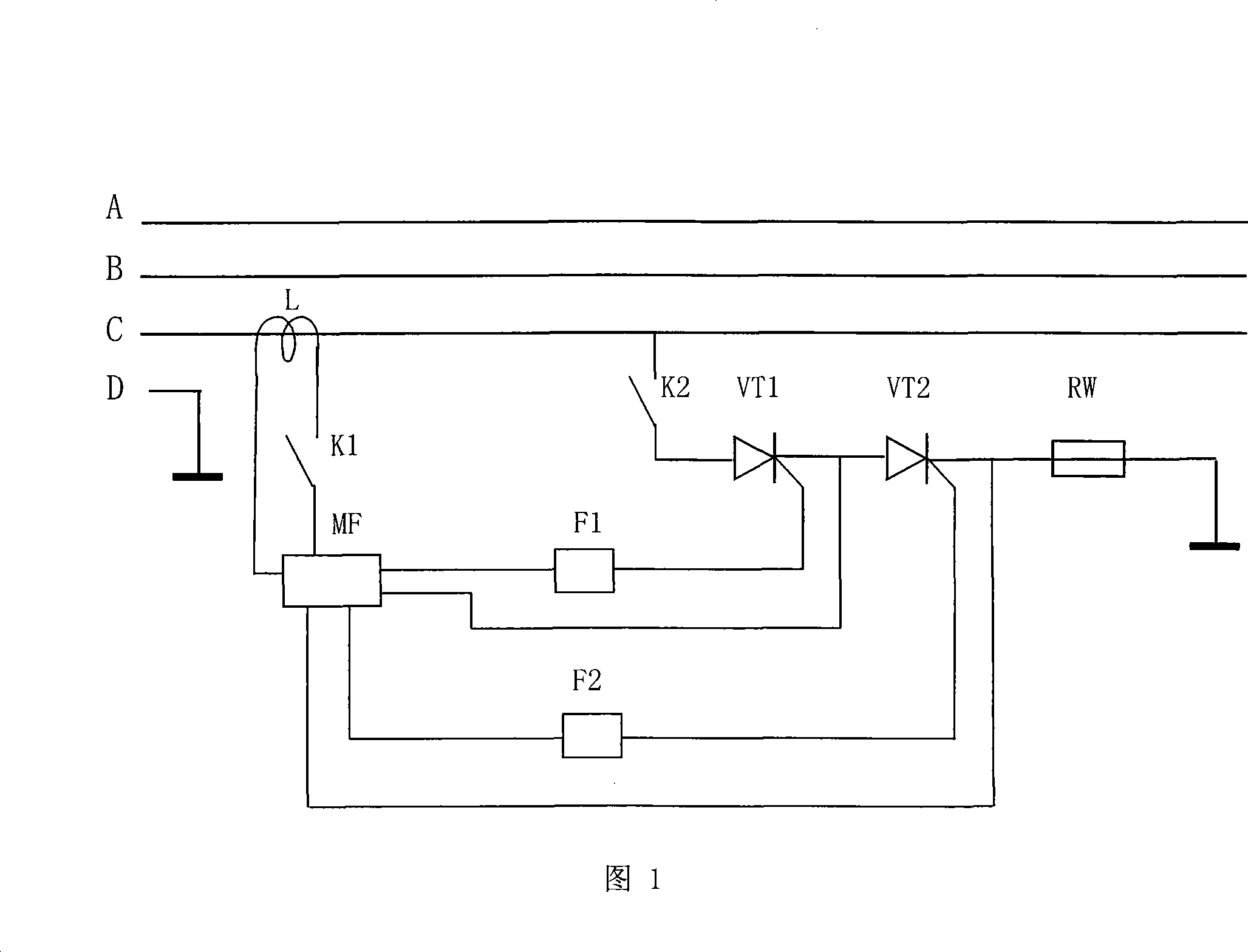

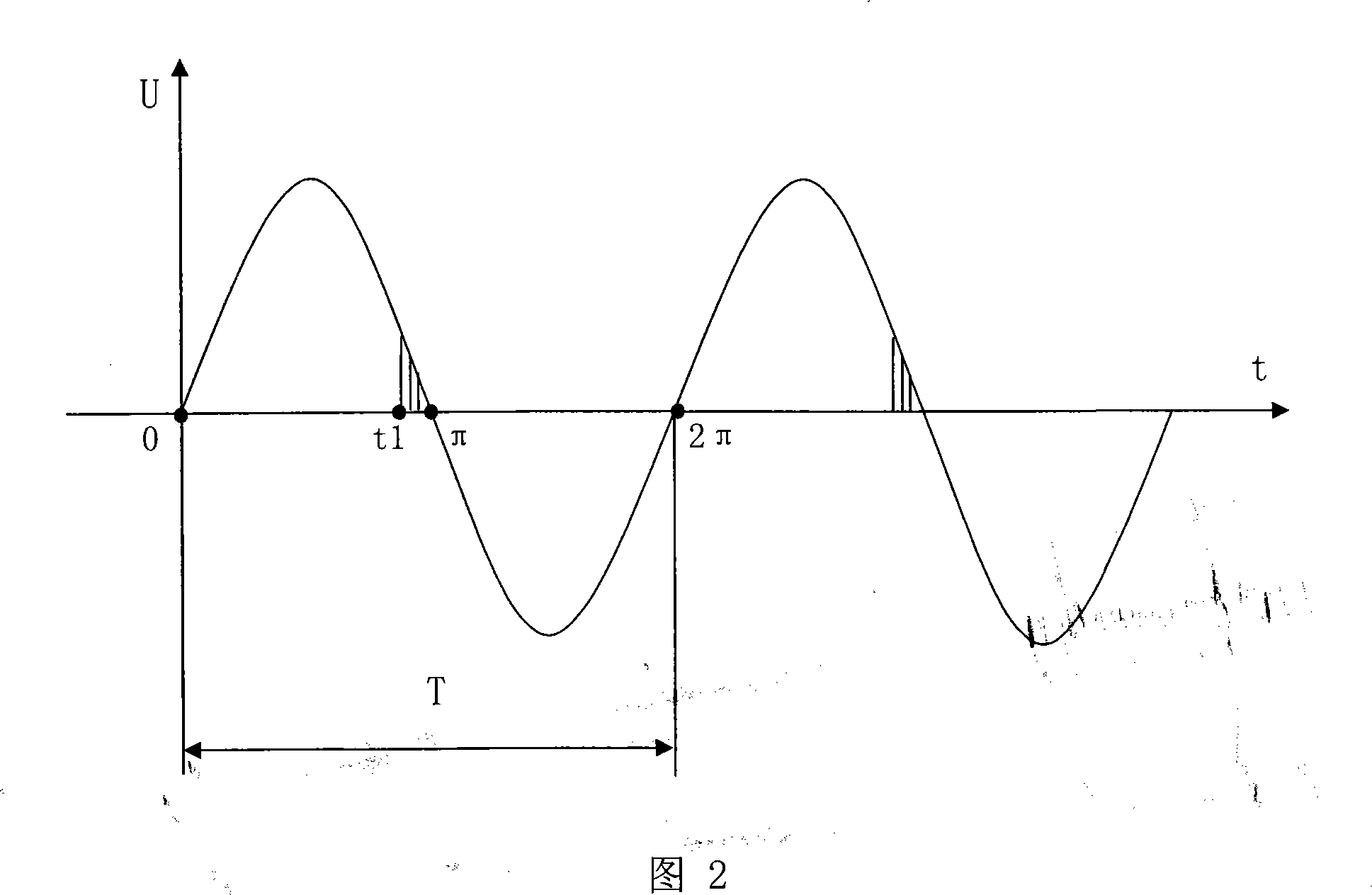

InactiveCN101242086BWon't cause an accidentOverhead installationAc network circuit arrangementsThyratronEngineering

The present invention provides a method for melting the ice on the overhead electric transmission line, under the original load of the three-phase electric transmission line by connecting the major loop of the thyristor between each phase line of the circuit with ice and the earth standing for the zero potential through an electric brake, the phases are respectively obtained from three phase lines, the phase signals are accessed into the respective pulse generator to generate lower-edge positive pulse by each generator, the positive pulse is used for triggering the control pole of thyristor in a same phase line to lead to the earth-conducting of the thyristor in order to increase the heat generating quantity of the conducting wire, the pulse generator is also provided with a pulse triggering time regulator with which the conducting time of the thyristor is controlled to lead to that the heat generating quantity of the electric transmission line confirms to the requirement for melting the ice thereby realizing the purpose that the power is not off when the ice is melted on the overhead electric transmission line.

Owner:傅雅芬

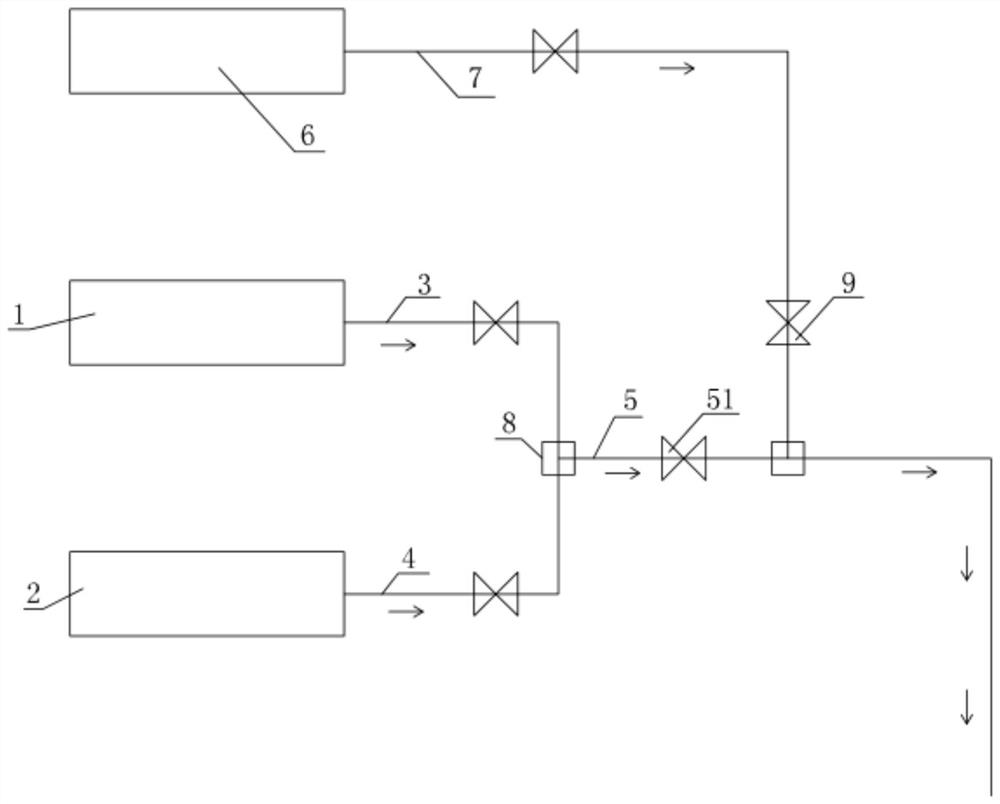

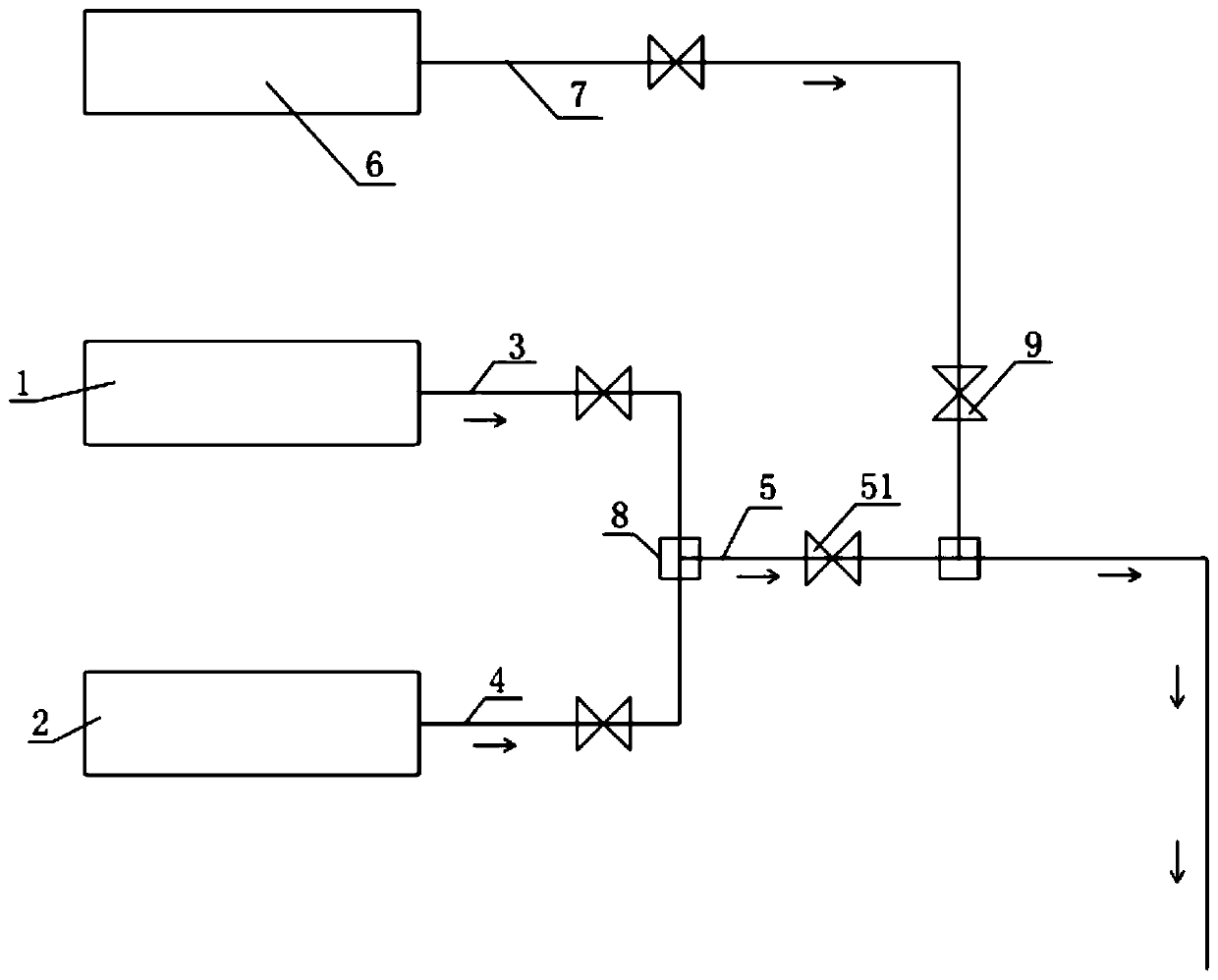

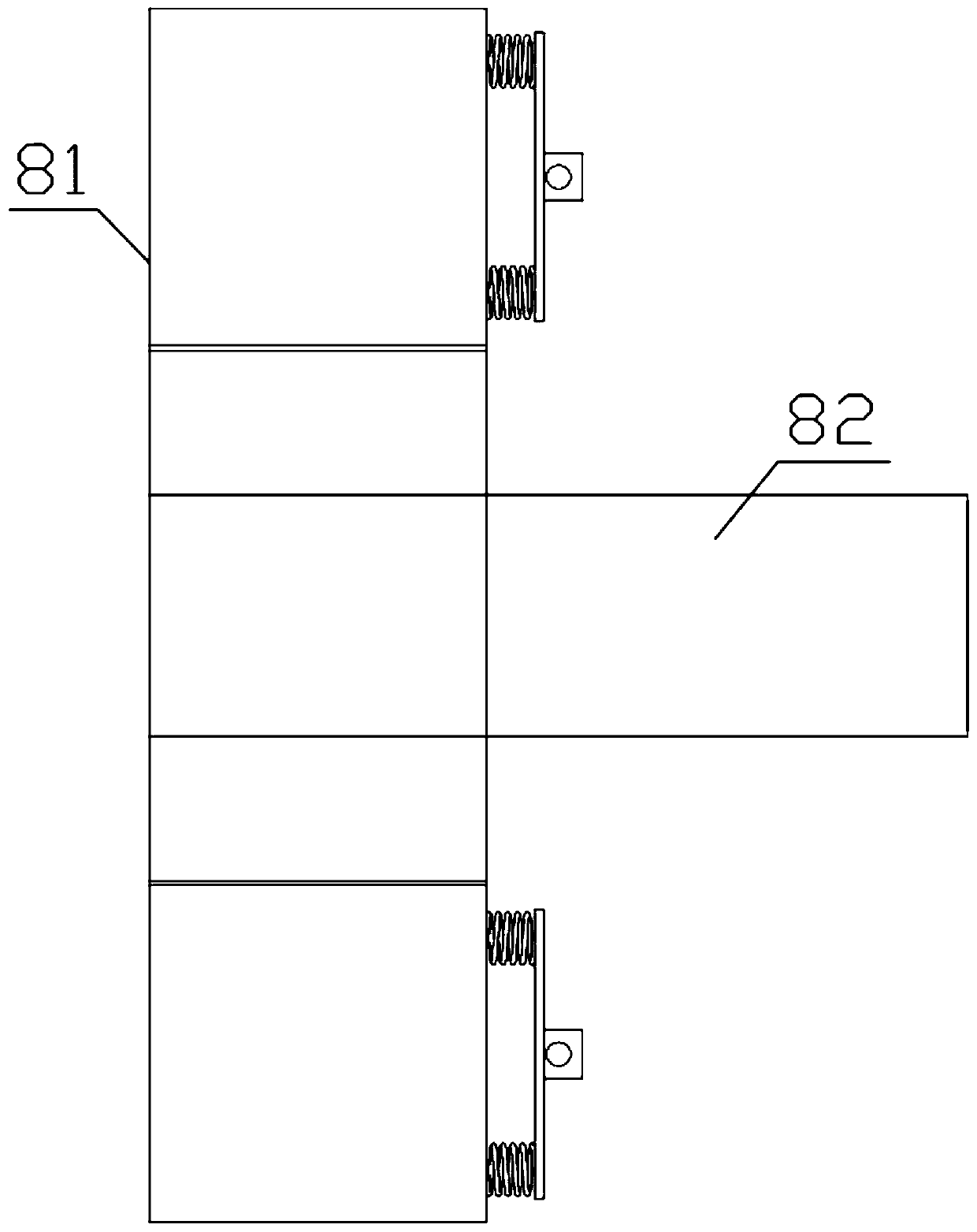

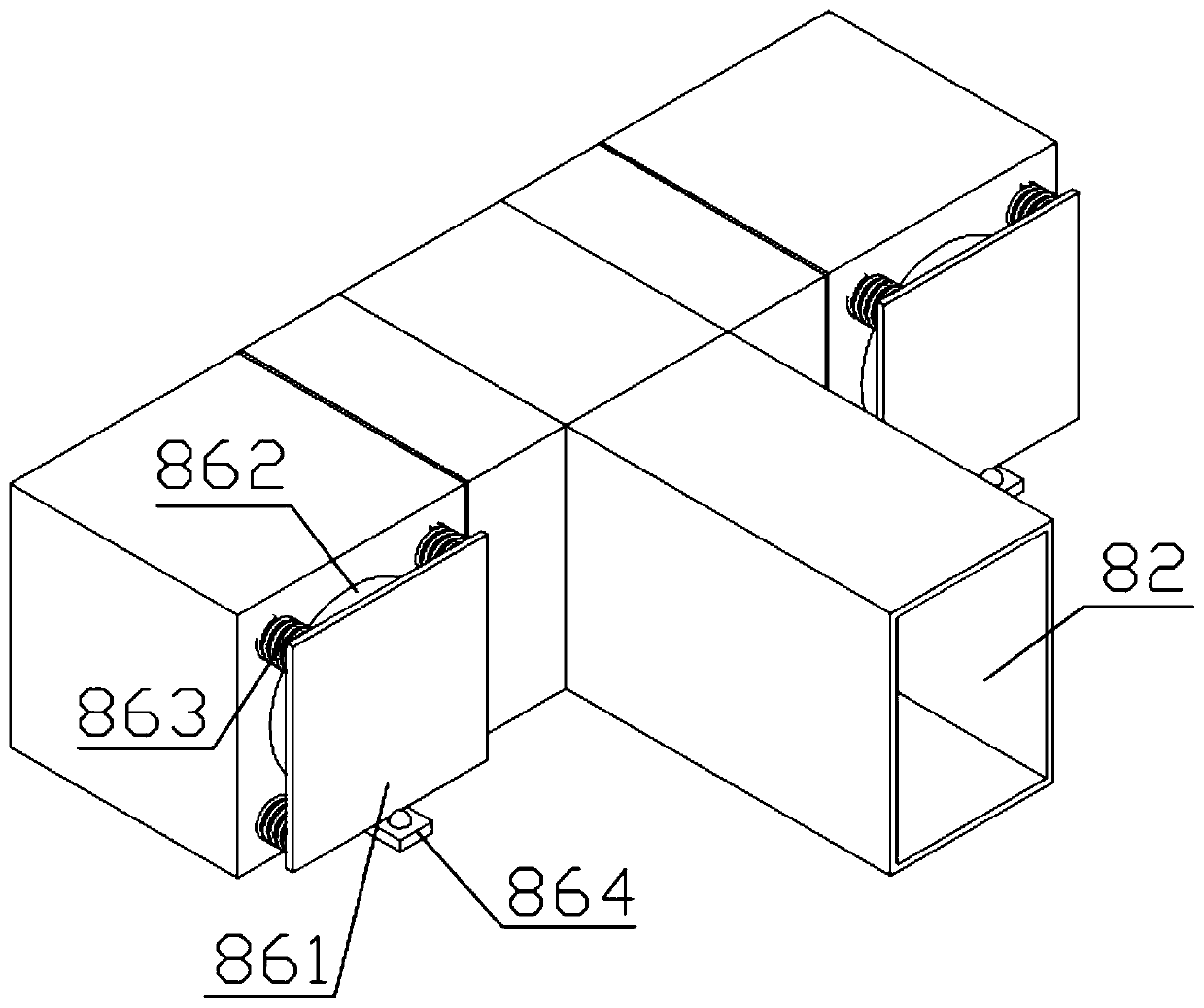

Air compressor air supply system

ActiveCN110630903BUniform pressureUniform pressure distributionPipeline systemsPump installationsEngineeringAir compressor

The invention discloses an air supply system for an air compressor, which includes a first air compressor and a second air compressor connected in parallel; an air compressor first ventilation pipeline connected to the first air compressor and a ventilation pipeline connected to the second air compressor The second ventilation pipeline of the air compressor; the third air compressor is connected to the main ventilation pipeline through the third ventilation pipeline of the air compressor; the first ventilation pipeline of the air compressor and the second ventilation pipeline of the air compressor are merged into the main ventilation pipeline A pressure balancer is provided at the position where the air compressor three ventilation pipelines are connected to the main ventilation pipeline; the pressure balancer includes two gas branch circuits and a gas main circuit. The air compressor air supply system of the present invention is suitable for long-distance gas pipelines, and can balance the air pressure and air flow of the air supply system connected to multiple air compressors, so that the air supply system can provide a relatively stable air flow .

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

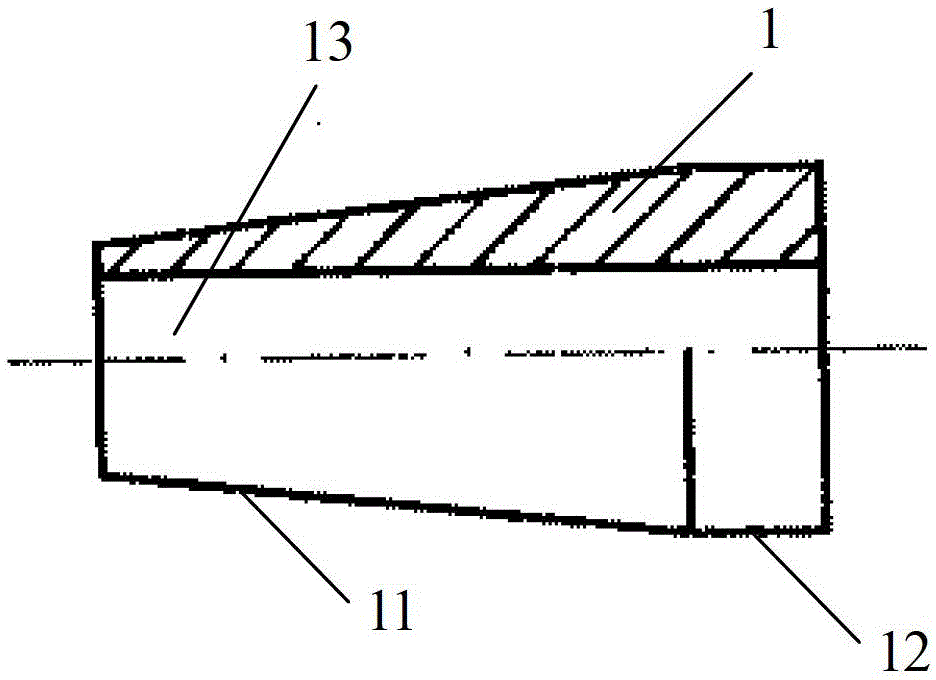

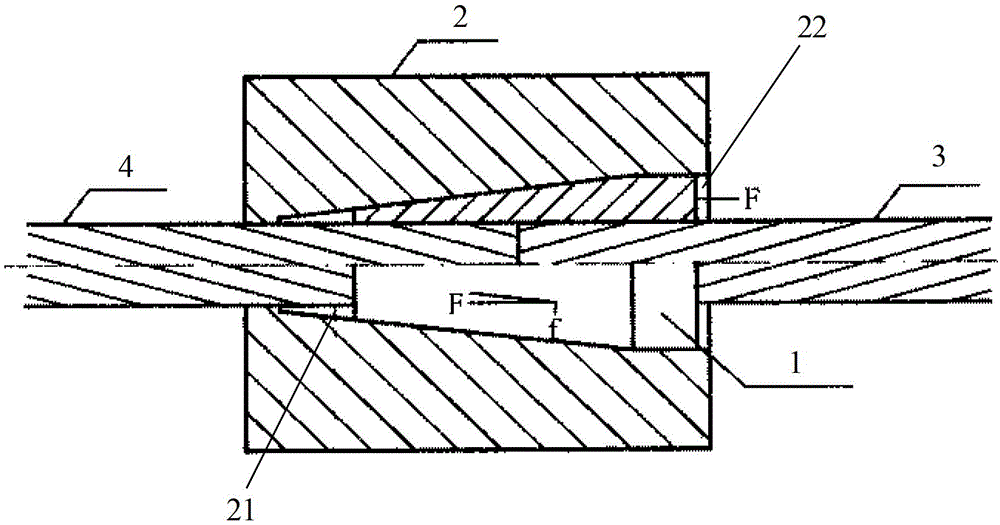

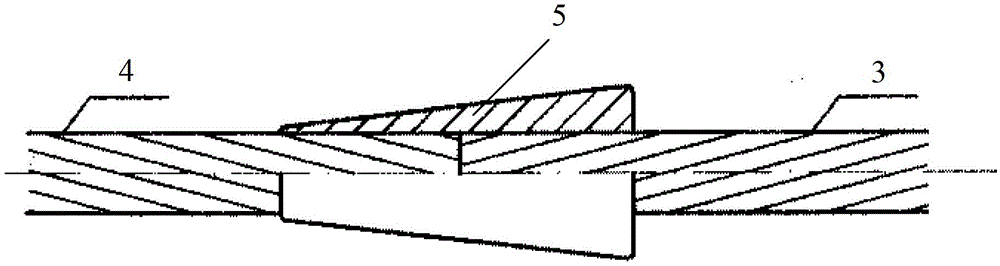

Connector used for conductor connection, connection device and cold link technology for conductor connection

InactiveCN102751596BHigh mechanical strengthHigh tensile strengthContact member manufacturingConnections effected by permanent deformationElectrical resistance and conductanceElectrical conductor

The invention relates to the field of the conductor connection, in particular to a connector used for conductor connection, a connection device and a cold link technology for conductor connection. The connector used for the conductor connection, the connection device and the cold link technology for conductor connection are widely applied to the processes, such as electric power, electric power construction and installation, and electric wire and cable manufacture, are used for the isometric connection or reducing connection for cable conductors and bare copper and aluminum stranded wires, and are also used for solving the problems of untight contact between the conductor and a connecting pipe, low tensile strength, big contact resistance, unsmooth surface, uneven electric field distribution and the like. The connection device is provided with a taper-shaped connector, a cold link die, a conductor I and a conductor II, wherein the center of the cold link die is in a pore structure cooperated with the taper-shaped connector; the taper-shaped connector is arranged in the pore structure; and the conductor I and the conductor II respectively extend into the connection pore of the taper-shaped connector for butt joint from two ends of the pore structure of the cold link die. After the cold link technology disclosed by the invention is adopted, the technology is advanced, the performance is excellent, and the product quality is stable. After the conductors are connected by the cold link technology, the connector and the conductors tightly contact to almost form a whole without any gap.

Owner:SHENYANG XINHE CABLE

An electric oil drum handling device

ActiveCN107399352BReduce labor intensityAvoid collision damageHand carts with multiple axesSelf lockingEngineering

The invention provides an electric oil bucket carrying device and belongs to the field of oil bucket carrying devices. The electric oil bucket carrying device comprises a frame, a clamping portion and a pull-lifting portion, wherein the frame comprises a semi-arc-shaped base plate at the lower portion, a top plate is arranged above the base plate, a vertical column and guide columns are arranged between the base plate and the top plate, the vertical column is arranged in the middle of the base plate, the guide columns are arranged at two ends of the base plate and provided with guide rails respectively, and wheels having self-locking functions are arranged in the middle and at two ends of the lower end face of the base plate. The clamping portion comprises moving parts arranged on the guide rails, wherein the moving parts are installed on the guide rails through wheel sets and slide along the guide rails. The pull-lifting portion comprises a driving device, a wire coil, a fixed pulley, a limiting ring and an upward pull rope. The problem that the labor cost for oil bucket carrying is high, and oil bucket carrying is unsafe and the like is solved.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

Ice and snow fusion method for air power transmission line

InactiveCN101242086ATo achieve the purpose of melting ice and snowWon't cause an accidentOverhead installationAc network circuit arrangementsPhase leadTransmission line

The present invention provides a method for melting the ice on the overhead electric transmission line, under the original load of the three-phase electric transmission line by connecting the major loop of the thyristor between each phase line of the circuit with ice and the earth standing for the zero potential through an electric brake, the phases are respectively obtained from three phase lines, the phase signals are accessed into the respective pulse generator to generate lower-edge positive pulse by each generator, the positive pulse is used for triggering the control pole of thyristor in a same phase line to lead to the earth-conducting of the thyristor in order to increase the heat generating quantity of the conducting wire, the pulse generator is also provided with a pulse triggering time regulator with which the conducting time of the thyristor is controlled to lead to that the heat generating quantity of the electric transmission line confirms to the requirement for melting the ice thereby realizing the purpose that the power is not off when the ice is melted on the overhead electric transmission line.

Owner:傅雅芬

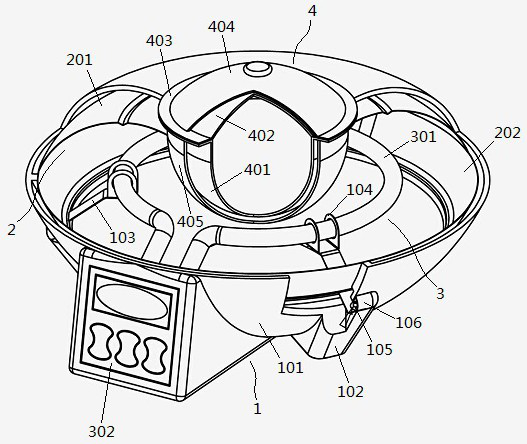

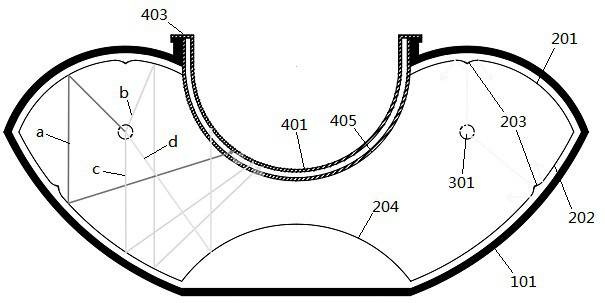

Integrated photo-thermal cooking range

PendingCN111964281AReduce working powerImprove securitySolar heating energySolar heat collector controllersEngineeringMechanical engineering

The invention discloses an integrated photo-thermal cooking range. The integrated photo-thermal cooking range comprises a supporting mechanism, a condensation mechanism, a heating mechanism and a thermal accumulation mechanism. The supporting mechanism comprises a shell and supporting sheet. The supporting feet are arranged at the bottom of the shell, and an opening is formed in the top end of theshell. The condensation mechanism comprises an upper condensation layer and a lower condensation layer of a concave face structure, and the upper condensation layer and the lower condensation layer are arranged on the inner side of the shell. The heating mechanism comprises a photo-thermal pipe and a controller, and the photo-thermal pipe is electrically connected with the controller and is located between the upper condensation layer and the lower condensation layer. The thermal accumulation mechanism comprises a pot body and a pot cover, the pot body is arranged at the opening of the top end of the shell, the pot cover is arranged on an upper opening of the pot body, and the pot body and the photo-thermal pipe are not in contact. The photo-thermal pipe is of an annular structure, and the two ends of the photo-thermal pipe are connected with the controller. Through the mirror surface condensation principle, the function of heating foods is achieved through the low-power thermal accumulation manner, and the integrated photo-thermal cooking range is low in work power and good in safety performance and is suitable for most living environments where high-power electrical appliances are forbidden to be used.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

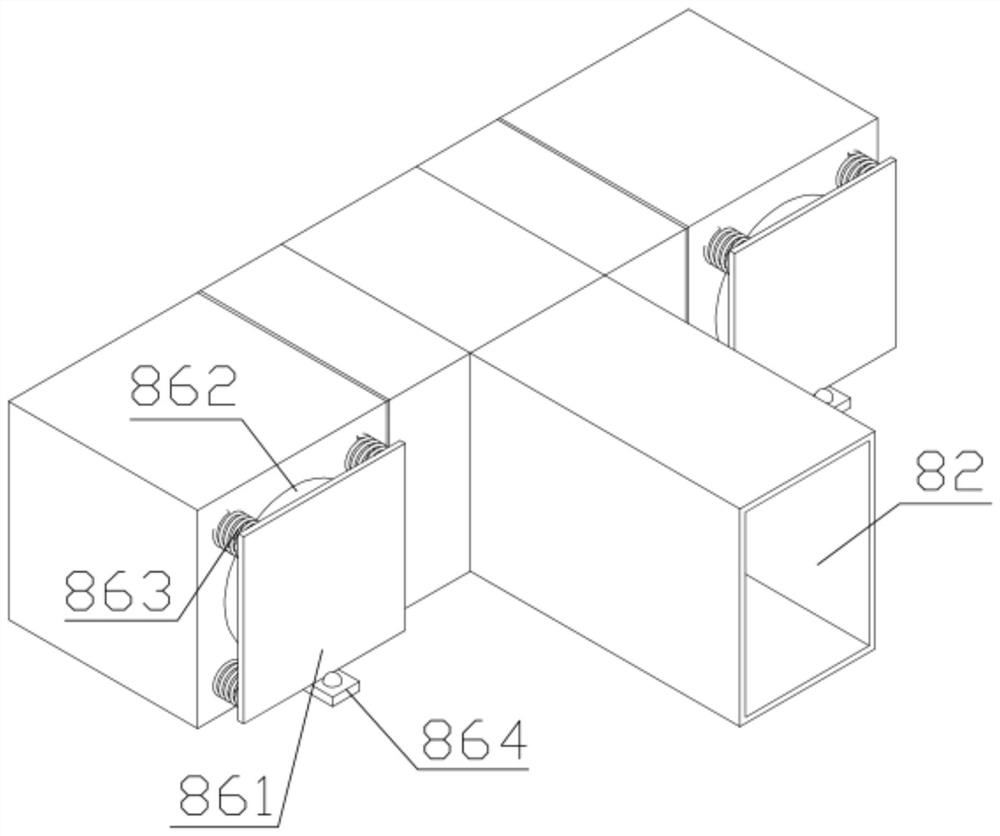

General safety plug-in mechanism for electrical appliance

InactiveCN108232752AWon't cause an accidentAchieve electrificationCoupling device detailsEngineeringScrew thread

The invention discloses a general safety plug-in mechanism for an electrical appliance. The general safety plug-in mechanism for the electrical appliance comprises a plug-in socket and a plug-in joint, wherein a sliding-plugging cavity is formed in the plug-in socket, plug-in grooves which are communicated with the outer part are symmetrically formed in the right end wall of the sliding-plugging cavity up and down, a sliding-plugging bracket can be mounted in the sliding-plugging cavity by gliding left and right, through grooves which are communicated left and right are symmetrically formed inthe sliding-plugging bracket upwards and downwards, a threaded rod is mounted in the sliding-plugging bracket in a screw thread fit manner, the right end of the threaded rod can be rotationally mounted on the right end wall of the sliding-plugging cavity, the left end of the threaded rod is in matching connection with a motor fixedly mounted on the left end wall of the sliding-plugging cavity, first grooves are symmetrically formed in the left end wall of the sliding-plugging cavity upwards and downwards, power supply blocks connected to the commercial power are fixedly mounted in the first grooves, plug-in openings open towards the sliding-plugging bracket are formed in the power supply blocks, conductive blocks which are matched with the plug-in openings are symmetrically arranged on the left end face of the sliding-plugging bracket upwards and downwards, elastic conductive blocks are fixedly mounted on the inner-side end walls of the plug-in grooves, second grooves are formed in the outer-side end wall of the through grooves, and contact switches which are connected with the motor are mounted in the second grooves.

Owner:韦敬生

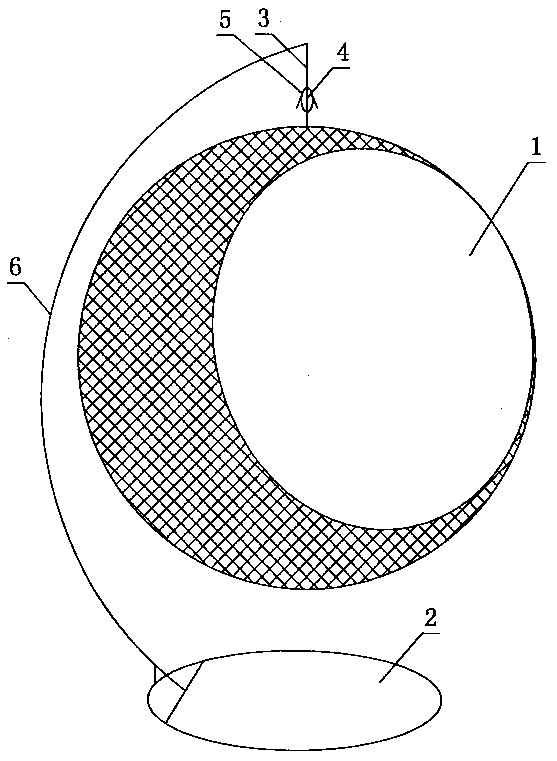

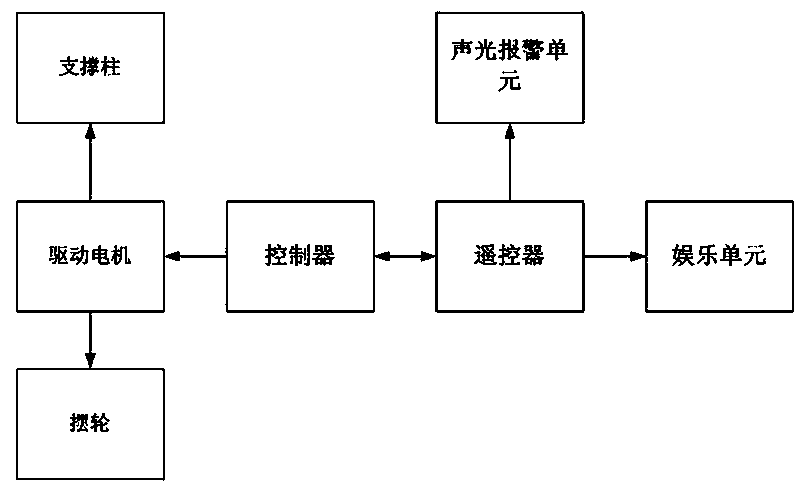

Multifunctional Hanging Basket Swing

Owner:FUNAN COUNTY TIANYI CRAFTS

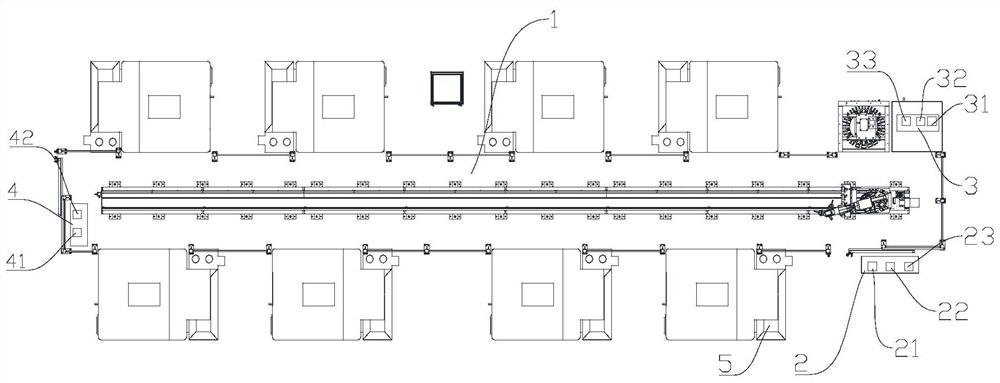

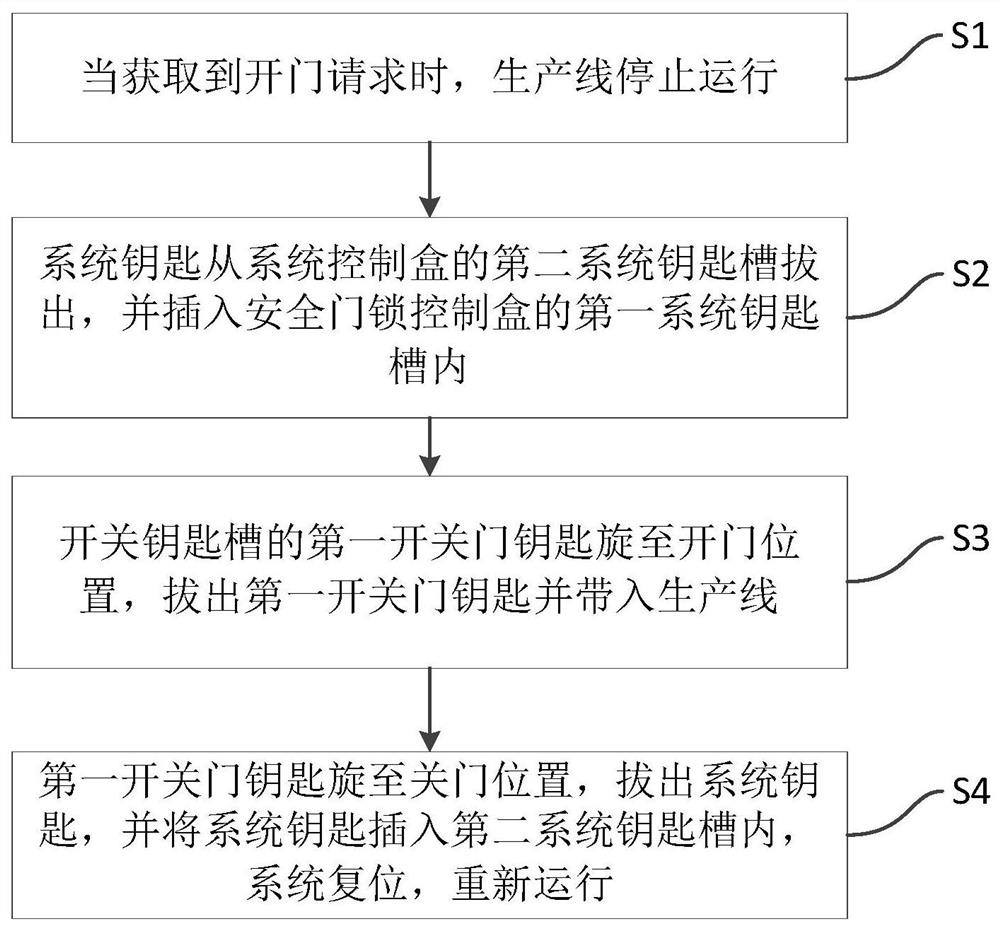

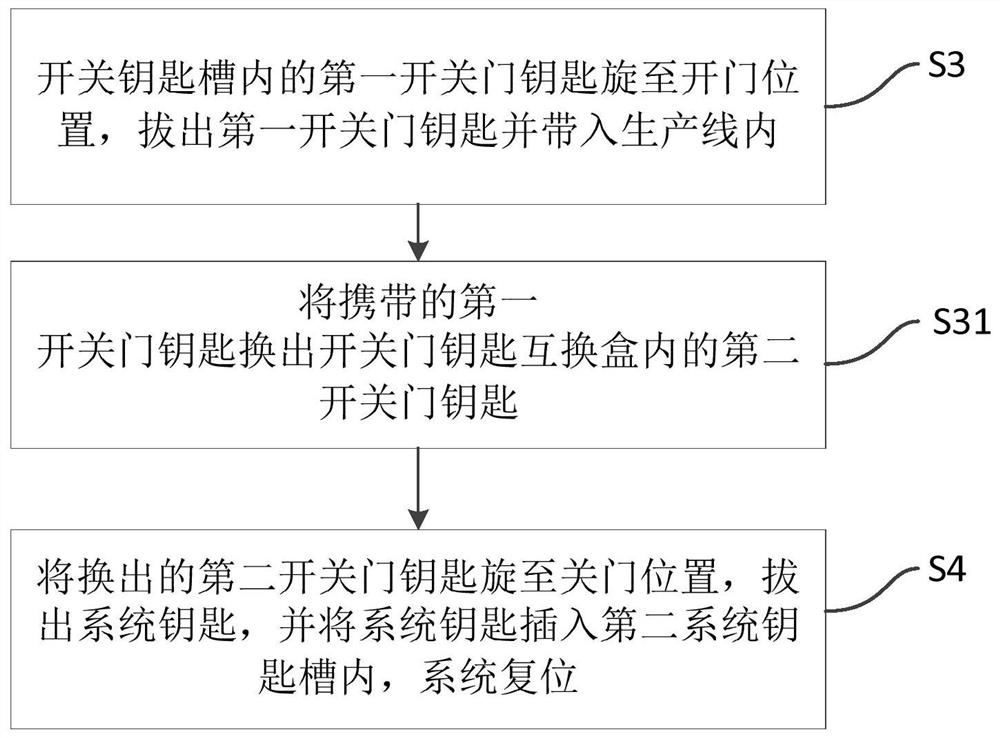

A control device and control method for a safety door lock in an automated production line

ActiveCN113250534BImprove security levelWon't cause an accidentAlarmsAlarm locksControl systemManufacturing line

The invention discloses a control device and a control method for a safety door lock in an automated production line. The control device includes: a safety door lock, the safety door lock is connected with a safety door lock control box, and the safety door lock control box is provided with a switch key slot and a first system key slot; The system control box has a second system key slot on the system control box; the system key controls the enabling of the system control box and the safety door lock control box; the first switch door key controls the opening or closing of the safety door lock; among them, the production line stops running Finally, pull out the system key in the key slot of the second system, and after inserting the key slot of the first system, the first switch door key can control the opening or closing of the safety door lock. The control device for the safety door lock of the automatic production line according to the present invention raises the safety level of the automatic production line to above the mechanical safety level B, so that accidents will not be caused even in the event of personnel misoperation or failure.

Owner:ZHUHAI GREE PRECISION MOLD CO LTD +1

Air compressor air supply system

ActiveCN110630903ABalanced pressure distributionEnsure safetyPipeline systemsPump installationsGas pipelineAirflow

The invention discloses an air compressor air supply system which comprises a first air compressor and a second air compressor connected in parallel. The system further comprises a first air compressor ventilation pipeline connected with the first air compressor and a second air compressor ventilation pipeline connected with the second air compressor. A third air compressor communicates with a main ventilation pipeline through a third air compressor ventilation pipeline; pressure balancers are arranged at the position where the first air compressor ventilation pipeline and the second air compressor ventilation pipeline are combined to the main air ventilation pipeline and at the position where the third air compressor ventilation pipeline communicates with the main air ventilation pipeline; and each pressure balancer comprises two gas branches and a gas main path. The air compressor air supply system is suitable for a long-distance conveying gas pipeline, air pressure and air flow of the air supply system connected with the plurality of air compressors can be balanced, and therefore the air supply system can provide stable air flow.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

An oil drum handling device

ActiveCN107472320BReduce labor intensityAvoid collision damageHand carts with multiple axesEngineeringMoving parts

The invention provides an oil drum carrying device, and belongs to the field of oil drum carrying equipment. The oil drum carrying device comprises a frame, clamping parts and a pulling-up part. The frame comprises a semi-circular arc-shaped bottom plate arranged at the lower part. A top plate is arranged over the bottom plate. Stand columns and guiding columns are arranged between the bottom plate and the top plate. The stand columns are arranged in the middle of the bottom plate. The guiding columns are arranged at the two ends of the bottom plate. The guiding columns are correspondingly provided with guiding rails. Vehicle wheels with self-locking parts are arranged at the middle and the two ends of the lower end surface of the bottom plate. Each clamping part comprises a moving part arranged on the guiding rails. The moving parts are installed on the guiding rails through wheel sets and slide along the guiding rails. The pulling-up part comprises a second wheel disc, a fixed pulley, a limiting ring and a pulling-up rope. By means of the oil drum carrying device, the problems that the manual cost needed by carrying an oil drum is high, and carrying is not safe are solved.

Owner:博白县计量和产品质量检测中心

Stable big data server

InactiveCN107681362AWon't cause an accidentAchieve electrificationCoupling device detailsComputer periphery connectorsEngineeringBig data

The invention provides a stable big data server. The stable big data server of the present invention comprises a socket and a plug; a sliding cavity is defined in the socket; plugging grooves which extend towards the outside in a through manner and are distributed symmetrically in a vertical direction are formed in the right side surface of the sliding cavity; a sliding frame is slidably mounted in the sliding cavity in a leftward and rightward slideable manner; channel grooves which extend along a left-and-right direction in a through manner and are distributed symmetrically in a vertical direction are formed in the sliding frame; a spiral rod is mounted in the sliding frame through spiral thread fit; the right end of the spiral rod is rotatably mounted in the right side surface of the sliding cavity, and the left end of the spiral rod is in matched connection with a motor which is fixedly mounted in the left side surface of the sliding cavity; first countersunk grooves which are distributed symmetrically in a vertical direction are formed in the left side surface of the sliding cavity; electrification contacts connected with a power source are fixedly mounted in the first countersunk grooves; plugging openings facing the sliding frame are formed in the electrification contacts; power connection contacts which are matched with the plugging openings and are distributed symmetrically in a vertical direction are arranged on the left side surface of the sliding frame; elastic power connection contacts are fixedly mounted in the inner side surfaces of the plugging grooves; second countersunk grooves are formed in the outer side surfaces of the channel grooves; and touch control ends which are connected with the motor are mounted in the second countersunk grooves.

Owner:郭林惠

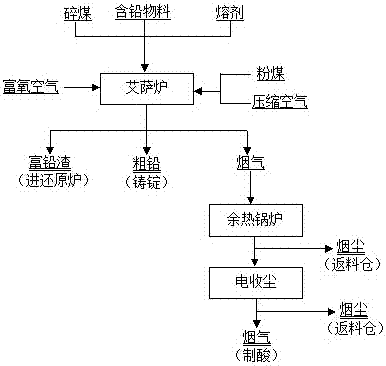

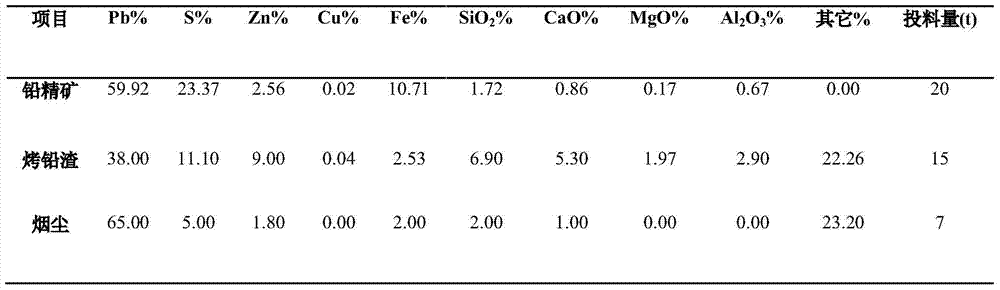

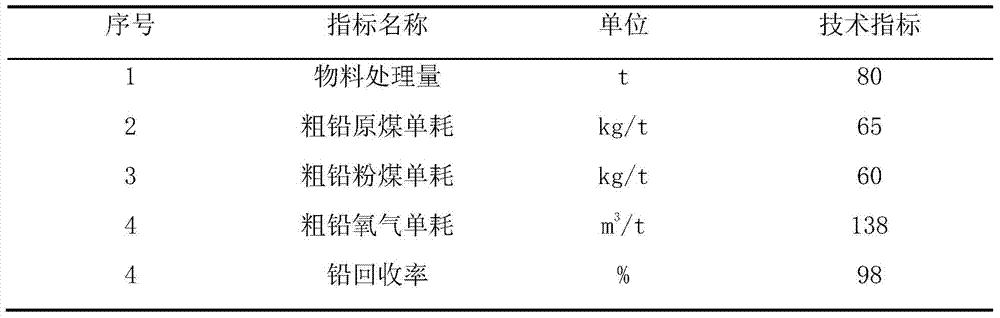

A lead smelting method using pulverized coal as injection fuel for Isa furnace

ActiveCN104775037BImprove energy savingAdaptableProcess efficiency improvementMelting tankLead smelting

The invention relates to a lead smelting method adopting pulverized coal as injection fuel in ISA furnaces, belonging to the technical field of pyrometallurgy. The method adopts the modes of continuous feeding and intermittent slag and lead discharge and comprises the following steps: 1) continuously adding lead concentrate, roasted lead slag, a flux, a slag former and a reducing agent to an oxygen-enriched top blowing furnace to be smelted; 2) sending the fuel in a spray gun into the spray gun by a Clyde pulverized coal system and injecting the fuel into a molten pool via a pulverized coal pipeline to sharply react with oxygen-enriched air to generate heat; 3) mixing loose coal used as the reducing agent with the raw materials and adding the mixture to the furnace; 4) adjusting the pulverized coal injection amount and the lifting height of the spray gun according to the temperature and height of the molten pool; 5) after separating lead and the slag, reducing the addition of the loose coal, adjusting the temperature of the molten pool, entering the stages of slag discharge and lead discharge and sending flue gases to an acid making system after waste heat and smoke dust in the flue gases are recovered by a waste heat boiler and an electric dust collector. As the pulverized coal is adopted as the fuel, the method is economical and low-carbon. The method operates efficiently, is simple to operate and has achieved industrial application.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

A self-adaptive dynamic pressure compensation system for deep sea current energy hydraulic turbine power generation

ActiveCN112879211BPower generation is green and cleanChange direction of motionMachines/enginesSafety/regulatory devicesWater turbineHydraulic pump

Owner:XI AN JIAOTONG UNIV

Connector type steel pipe scaffold

InactiveCN103899081AImprove energy savingSignificant energy saving and efficiency increaseScaffold connectionsJackscrewEngineering

The invention discloses a connector type steel pipe scaffold which comprises circular pipes, connectors, jackscrews, connecting plates, diagonal bracing connectors, cantilever connectors and bolts. The connector type steel pipe scaffold has the advantages that each single connector can be connected with steel pipes in six directions, and each diagonal bracing connector can be connected with steel pipes in five directions and four diagonal bracing rod pieces; the diagonal bracing rod pieces comprise the steel pipes, the jackscrews and connecting plates, and the lengths of the diagonal bracing rod pieces can be adjusted via the jackscrews, so that various length requirements of diagonal bracings can be met; diagonal bracings of the scaffold comprise the connecting plates and the diagonal bracing connectors, and the connecting plates and the cantilever connectors are connected with one another to form diagonal bracings of cantilever frames.

Owner:耿永田 +1

Database server

InactiveCN108232751AWon't cause an accidentAchieve electrificationCoupling device detailsComputer periphery connectorsDatabase serverMechanical engineering

The invention discloses a database server. The database server comprises a socket and a plug, wherein a sliding cavity is formed in the socket; inserting slots running through the outside are formed in the right side surface of the sliding cavity in longitudinal symmetry; a sliding frame is mounted in the sliding cavity in a left-and-right slidable manner; passage slots running through left and right are formed in the sliding frame in longitudinal symmetry; a threaded rod is mounted in the sliding frame in threaded fit; the right end of the threaded rod is rotatably mounted in the right side surface of the sliding cavity, and the left end thereof is connected with a motor fixedly mounted in the left side surface of the sliding cavity in a matching manner; first sunk slots are formed in theleft side surface of the sliding cavity in longitudinal symmetry; electrifying contacts connected with a power supply are fixedly mounted inside the first sunk slots; inserting matching ports of which end ports face the sliding frame are formed in the electrifying contacts; power connecting contacts matched with the inserting matching ports are arranged on the left side surface of the sliding frame in longitudinal symmetry; elastic power connecting contacts are fixedly mounted in the inner side surfaces of the inserting slots; second sunk slots are formed in the outer side surfaces of the passage slots; touch control ends connected with the motor are mounted inside the second sunk slots.

Owner:韦文生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com