Torrefaction method for pre-baked anode for aluminum

A prebaked anode and roasting technology, which is applied in the field of improvement of the roasting process in the production process of aluminum prebaked anodes, can solve problems such as equipment burnout, workshop shutdown, and product qualification rate impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

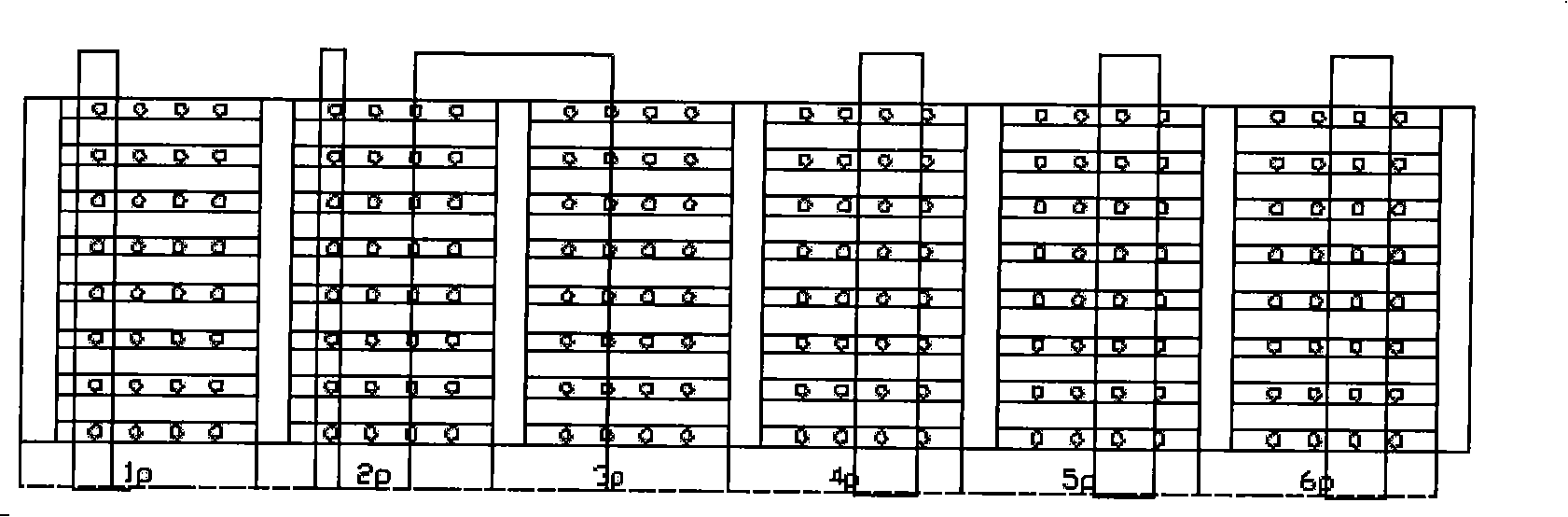

[0009] A prebaked anode roasting method for aluminum, in which the initial value of 2P is controlled to be 350°C±20°C and the end point value is 750°C±20°C during the roasting process.

[0010] For example, at the 1P position, since the temperature measurement point at the 1P position is occupied by the pipe, and the temperature measurement at the 1P position has no practical significance for the entire temperature control, no temperature measurement point is set; at the 3P position, a large amount of volatile components volatilize, And the temperature value will fluctuate from high to low after the volatile matter volatilizes; at the same time, the temperature rise rate in the volatile matter volatilization stage can reach about 20°C in an instant (and the temperature of the product does not rise rapidly). Therefore, the 3P temperature point is not controlled. The end temperature of point 2P1 is controlled at around 750°C. The final temperature value of point 4P1 is based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com