Negative-pressure dust treatment system for bulk grain unloading pit

A technology for dust treatment and grain pits, which is applied in the fields of removing smoke and dust, separating dispersed particles, and filtering dispersed particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the drawings and specific embodiments, so that those skilled in the art can understand.

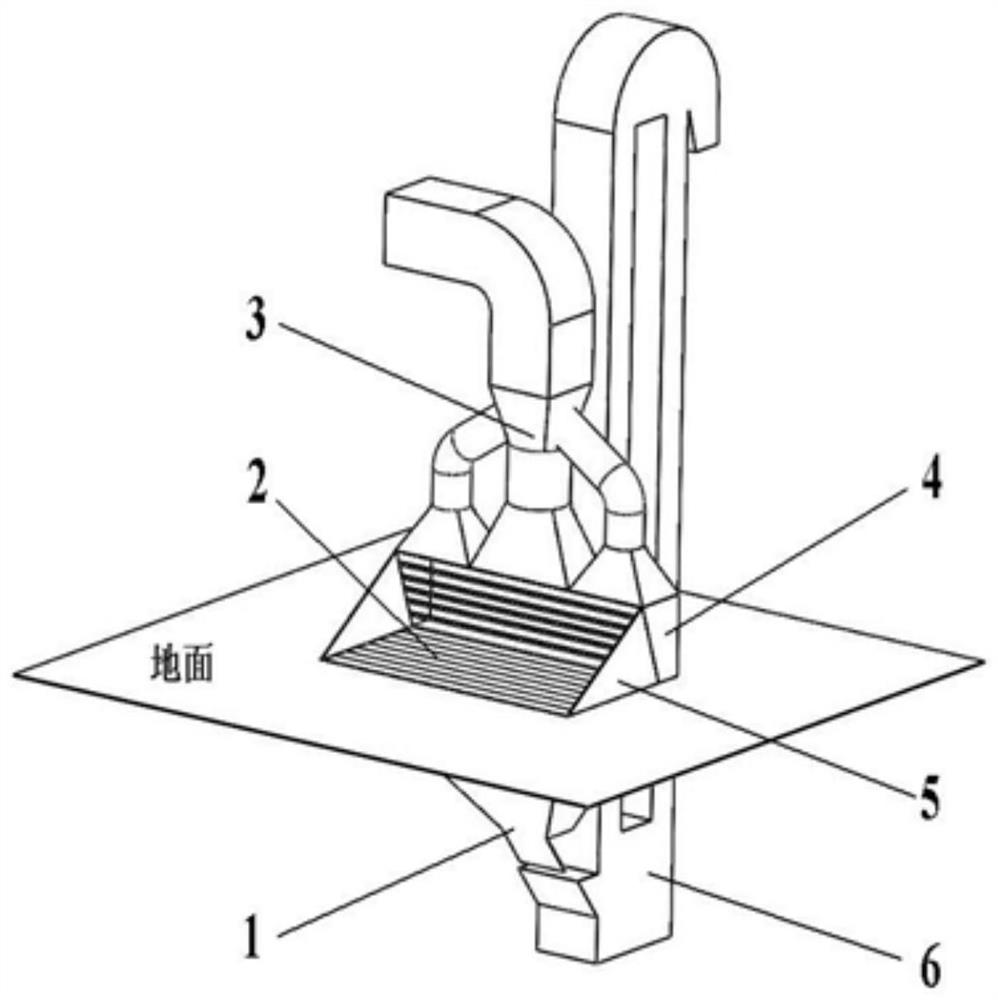

[0021] Such as figure 1 The negative pressure dust treatment system for the bulk grain unloading pit shown includes a grain unloading pit 1, a side suction hood 4, a ventilation duct 3 connected to the air outlet on the top of the side suction hood 4, and a ventilation duct 3 located at the side suction hood 4. Main suction hood 2 and bucket elevator 6 ahead.

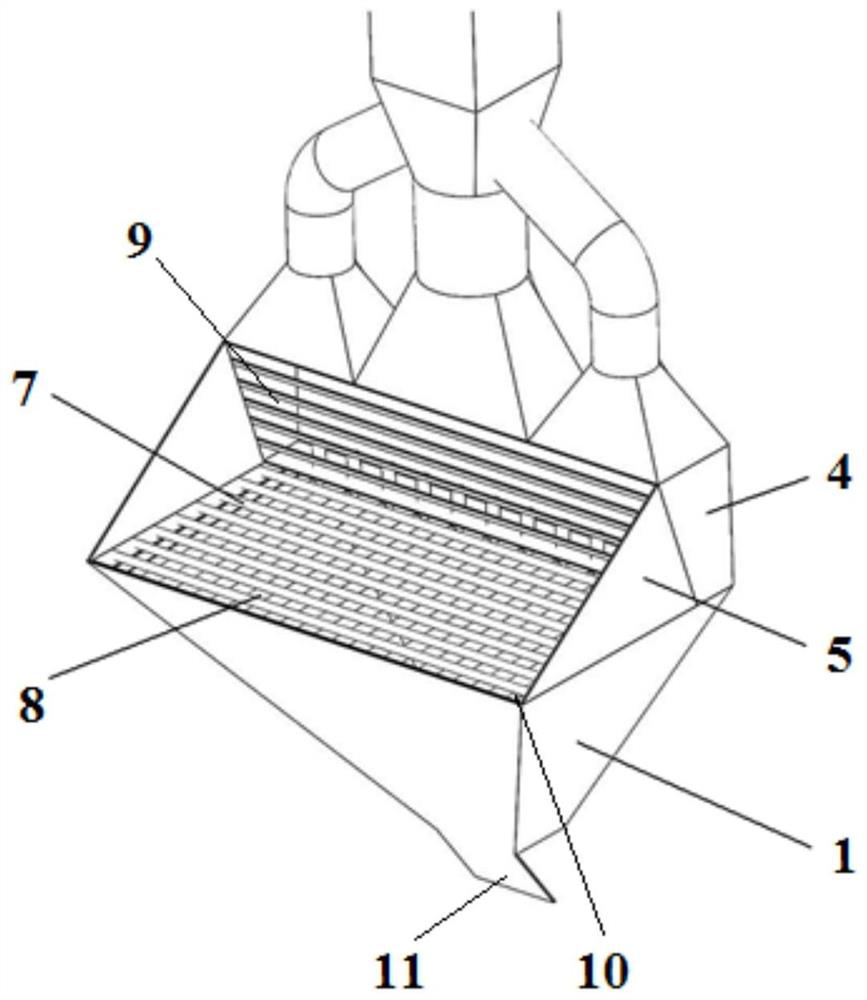

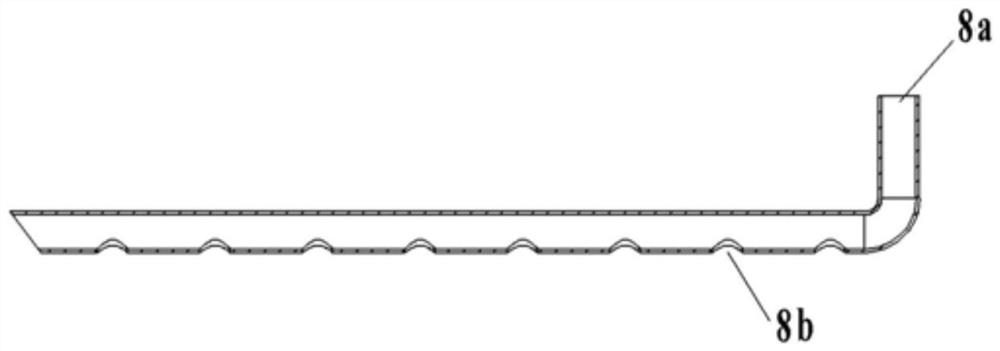

[0022] The main suction hood includes a ground suction pipe network 10 and a side grid 9 connected to the rear side of the ground suction pipe network 10 , and the side grid 9 communicates with the front air inlet of the side suction hood 4 . The ground suction pipe network 10 is a grid pipe network composed of horizontal steel pipes 7 and vertical steel pipes 8. The grid pipe network can initially screen the raw grains entering the grain unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com