Renewable particulate matter filter assembly

A technology for filtering components and particulate matter, which is applied in the fields of filtration and separation, filter regeneration, separation methods, etc., can solve the problems of difficulty in collecting and processing particulate matter, shortening the use and maintenance cost, and long cleaning and maintenance cycle, and achieves good cleaning effect, guarantees cleanliness, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

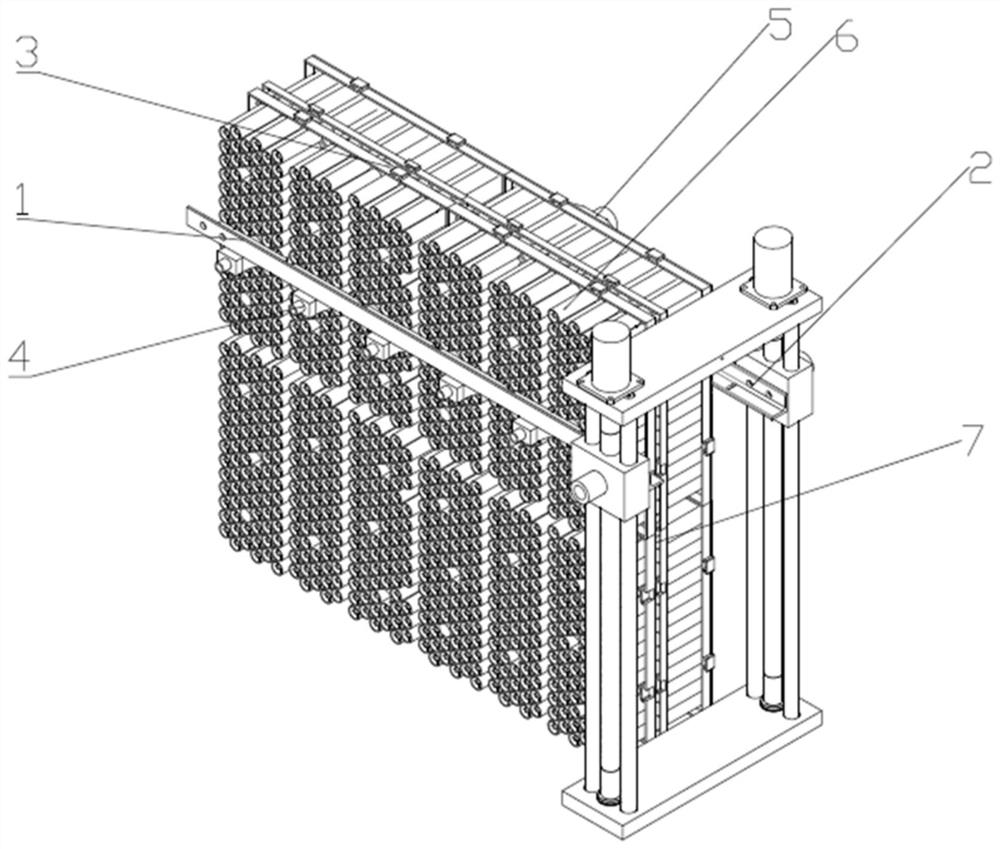

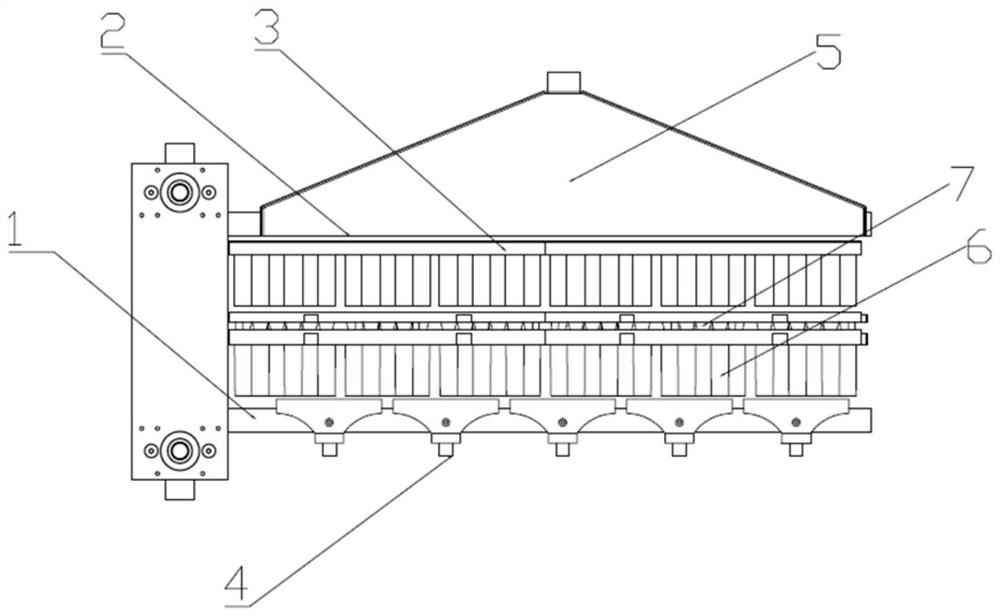

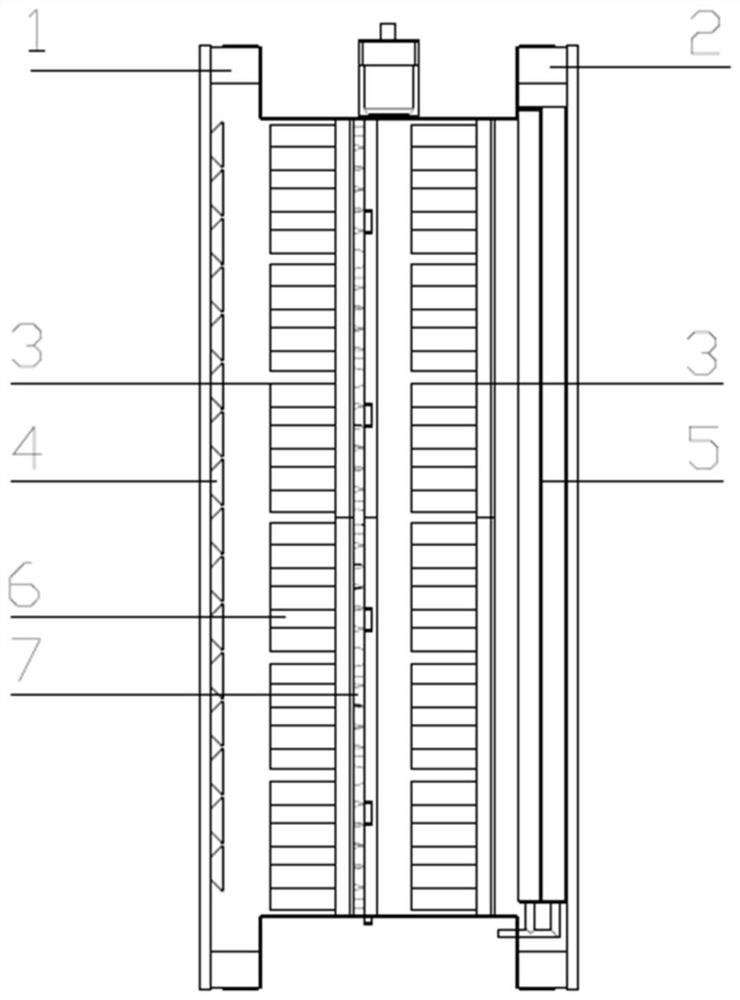

[0026] The present invention provides a renewable particulate filter assembly such as Figure 1 ~ Figure 3 As shown, a preferred embodiment of the present invention is shown therein.

[0027] Such as figure 1 , figure 2 As shown, it includes at least one cyclone mechanism 3 arranged along the direction of gas circulation, and the steam emitting assembly 1 and the steam receiving assembly 2 respectively arranged on the air inlet side and the air outlet side of the cyclone mechanism 3, and the steam emitting assembly 1 and The steam receiving component 2 can reciprocate along the end surface of the cyclone mechanism 3, and the reciprocating motion ensures the cleaning times of the steam cleaning, and the cleaning component can carry out multiple reciprocating motions according to the demand to drive the steam emitting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com