A light guide performance detection device applied to an LED light guide plate

A detection device and light guide plate technology, which is applied in the direction of measuring device, optical performance test, optical instrument test, etc., can solve problems such as the inability to measure the light guide performance of the LED light guide plate, the inability to detect, and the inability to drive the LED light guide plate to adjust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

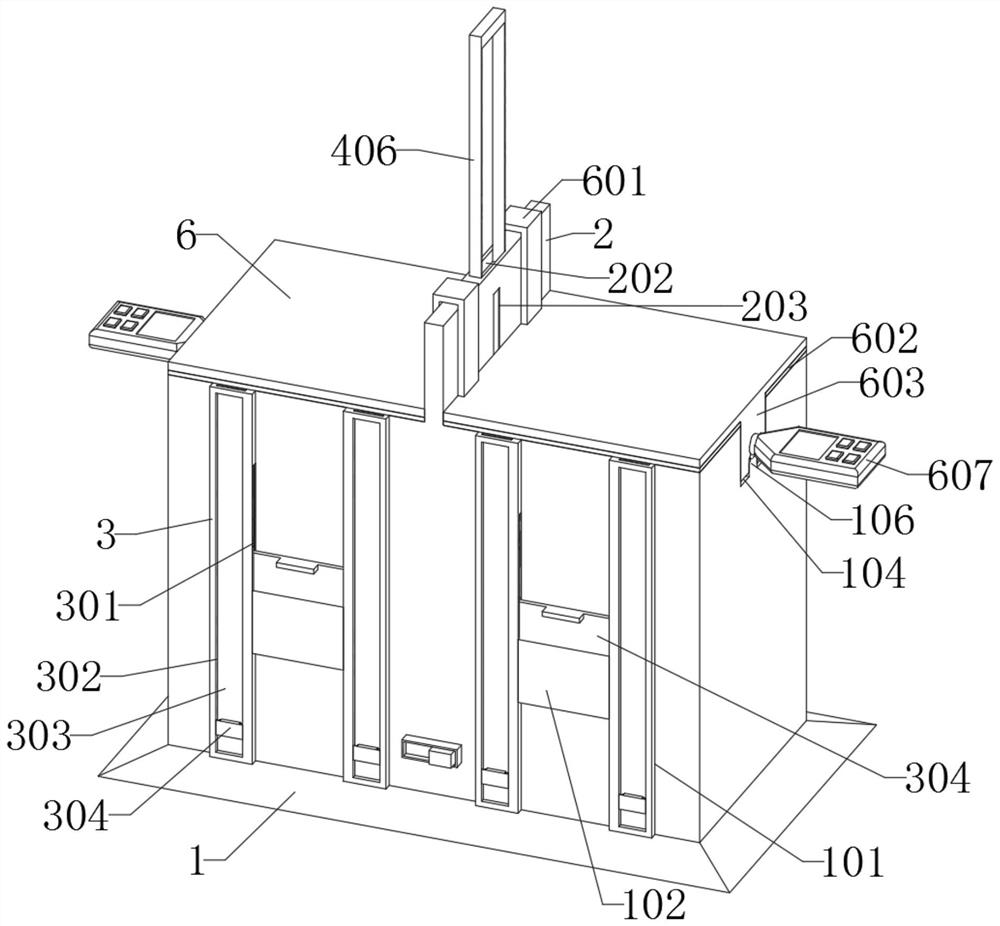

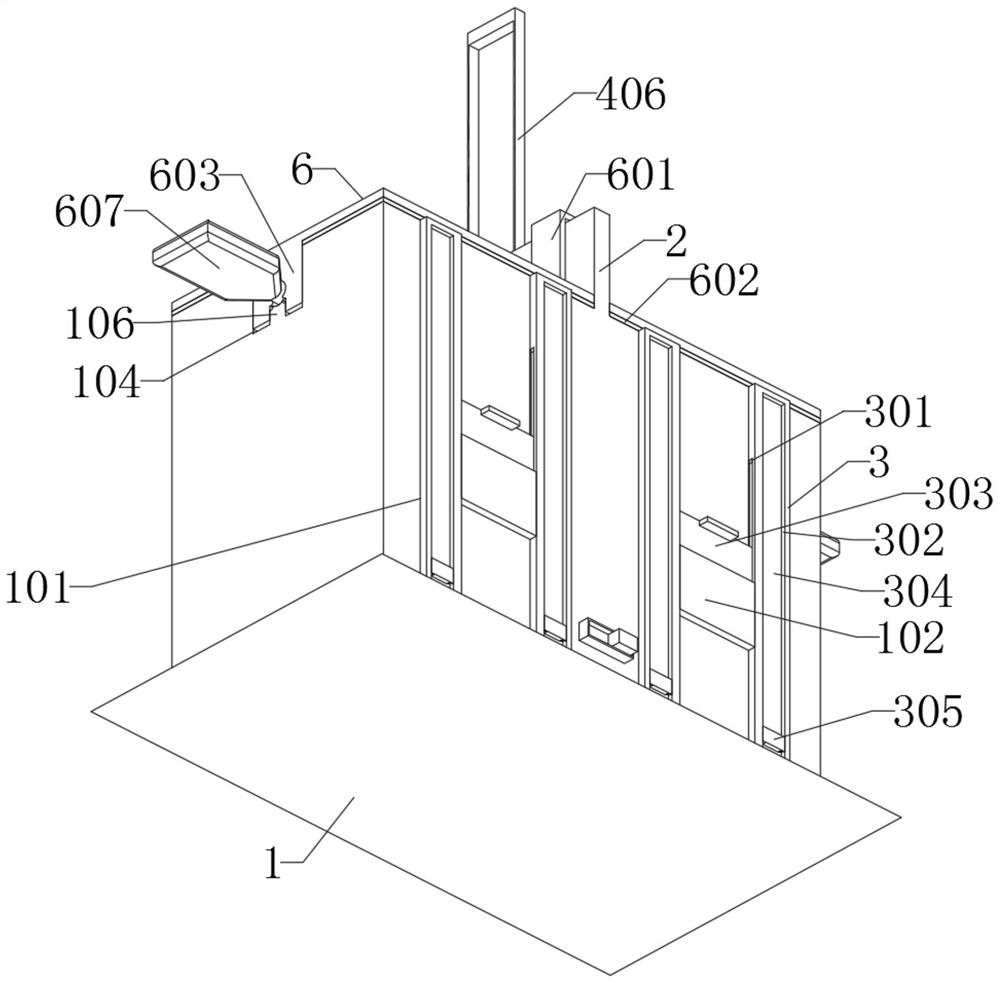

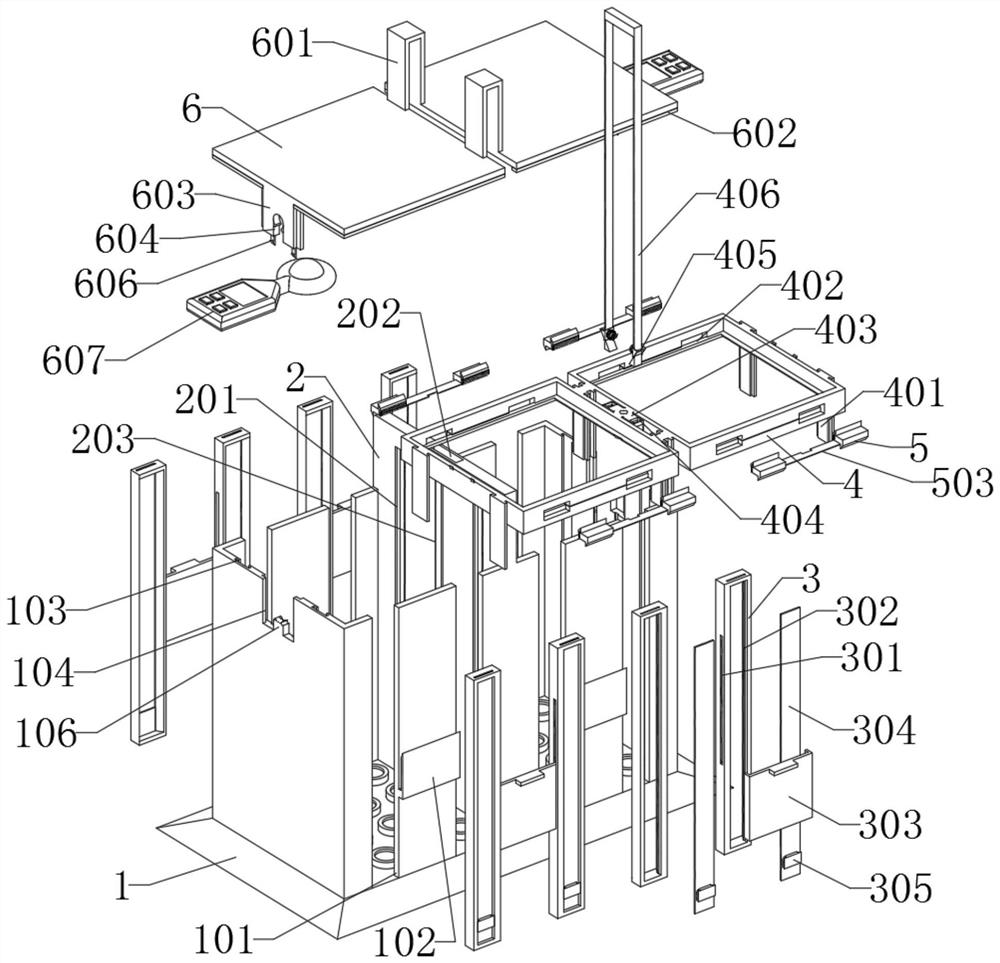

[0082] as attached figure 1 To attach Figure 11 Shown:

[0083] The invention provides a light guide performance detection device applied to LED light guide plates, which includes a main body 1; A spotlight is installed at the bottom, and a partition 2 is fixedly installed in the middle of the main body 1. Eight mounting parts 3 are installed on both sides of the main body 1 through side grooves 101. The top of the main body 1 is covered with a top plate 6; the partition 2, The partition 2 is a T-shaped structure, and the partition 2 is made of metal, and the middle groove 203 of the partition 2 is embedded with a slider 403 for installing the moving part 4; the installation part 3 is a rectangular strip structure, and the installation The part 3 is made of rubber; the moving part 4, the moving part 4 also includes a control mechanism, and the control mechanism is installed inside the stress groove 404 of the moving part 4. The moving part 4 is composed of two rectangular f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com