Fault diagnosis and test method based on proportional valve shaft controller

A technology of fault diagnosis and testing method, applied in the fields of instruments, character and pattern recognition, computer parts, etc., which can solve the problems of limited experimental data of proportional valve shaft controller and overfitting of proportional valve shaft controller fault classification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

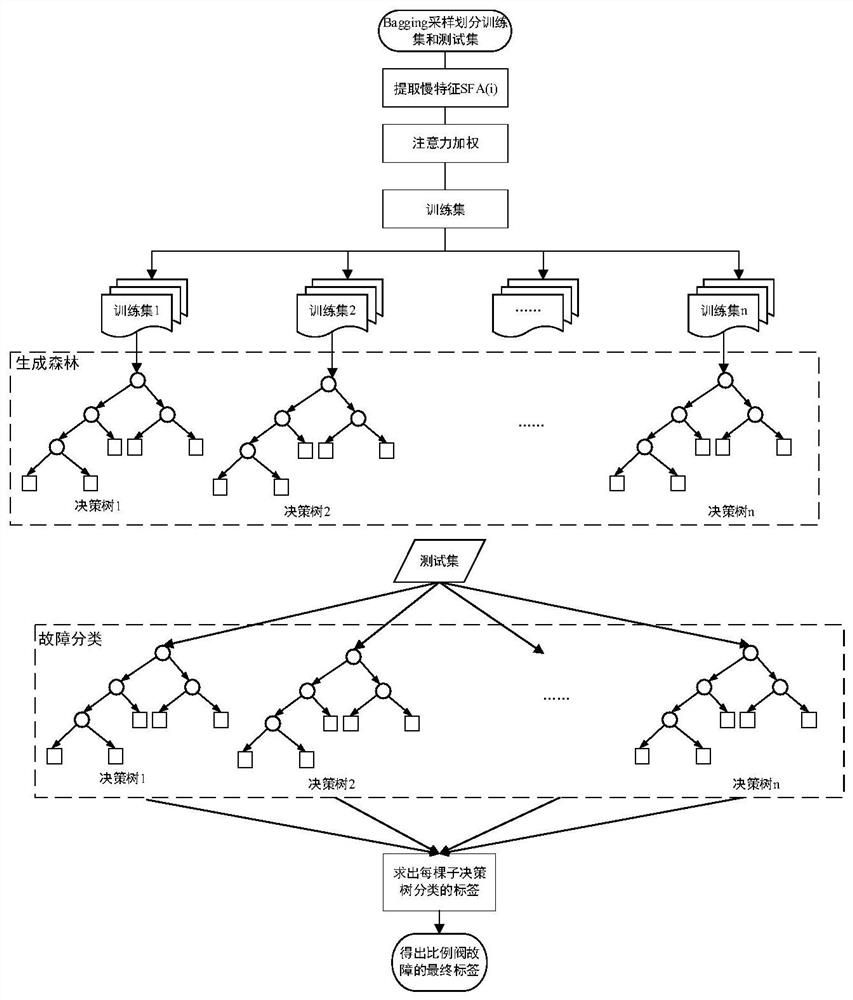

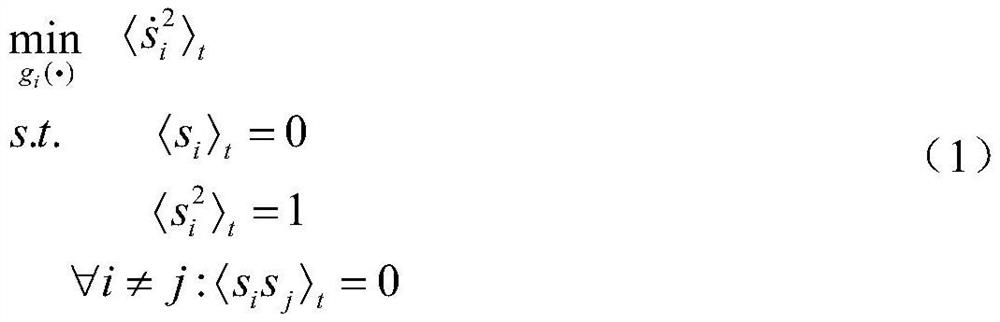

[0022] The invention provides a fault diagnosis and testing method based on a proportional valve axis controller. Firstly, the slow feature analysis algorithm is used to extract the slowly changing information in the proportional valve fault, and the slow feature is weighted through the spatial attention weighting mechanism to improve the importance of fault discrimination. The weight of the feature weakens the weight of non-important features for fault discrimination, and re-calibrates the slow features to obtain new slow features weighted based on the spatial attention mechanism. Finally, the random forest algorithm is used to realize the fault diagnosis of the proportional valve. The overall algorithm principle flow process of the present invention is as figure 1 As shown, the specific steps are as follows:

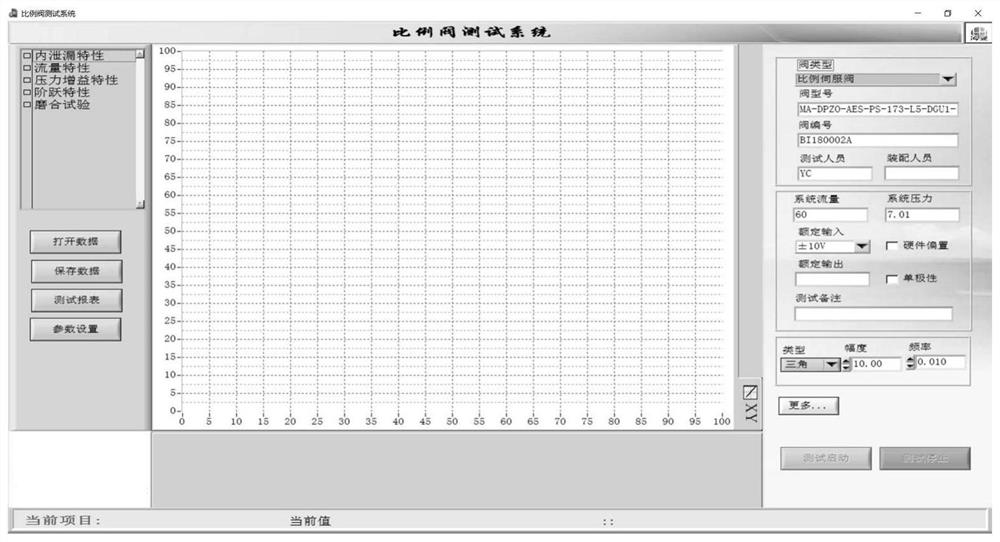

[0023] Step 1: Collect the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com