Cutting equipment for the production of stapler sutured titanium nails

A technology for cutting equipment and staplers, which is applied in the direction of mechanical equipment, nails, cleaning methods and utensils, etc. It can solve the problems of tissue damage and insufficient sharpness of the cutting place, and achieve the effect of improving the yield rate, facilitating medical standardization, and overall consistent shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

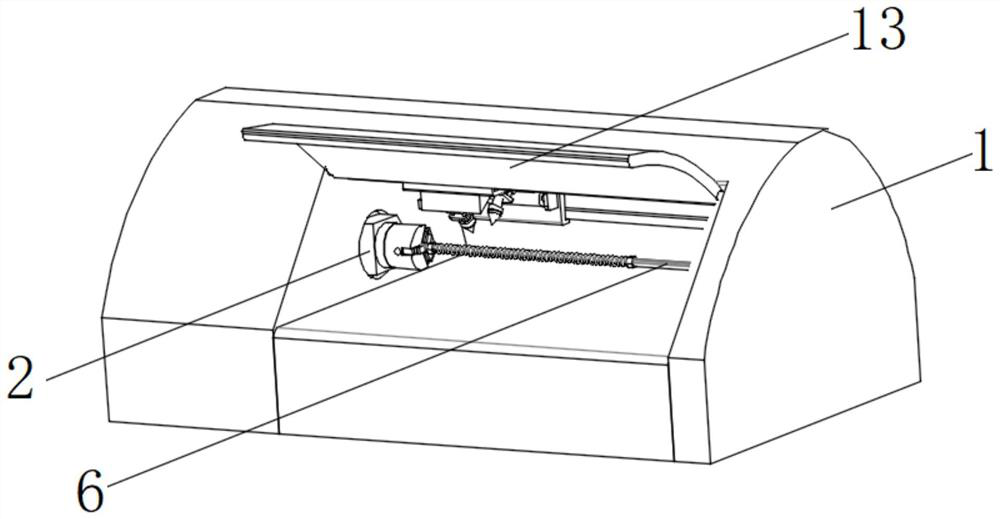

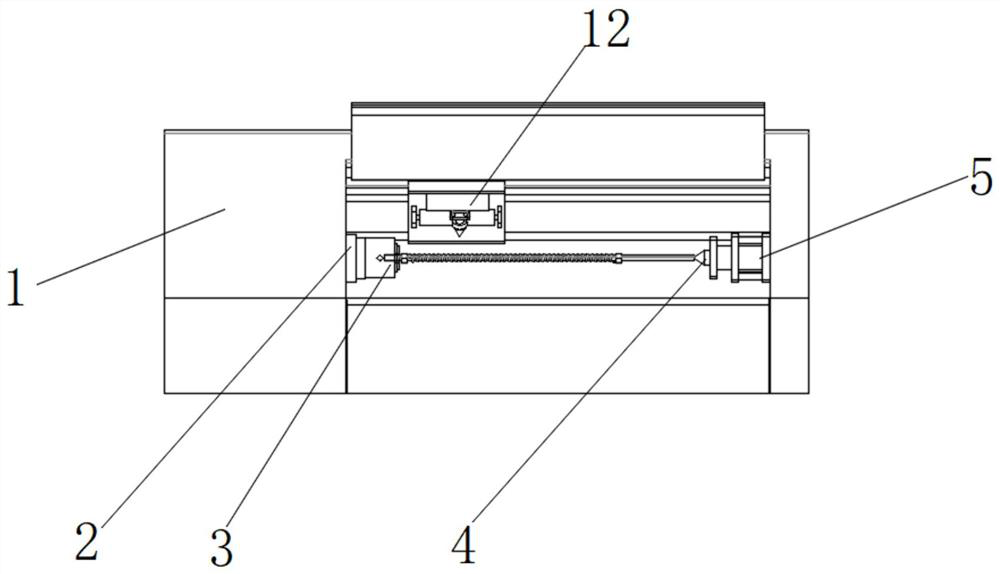

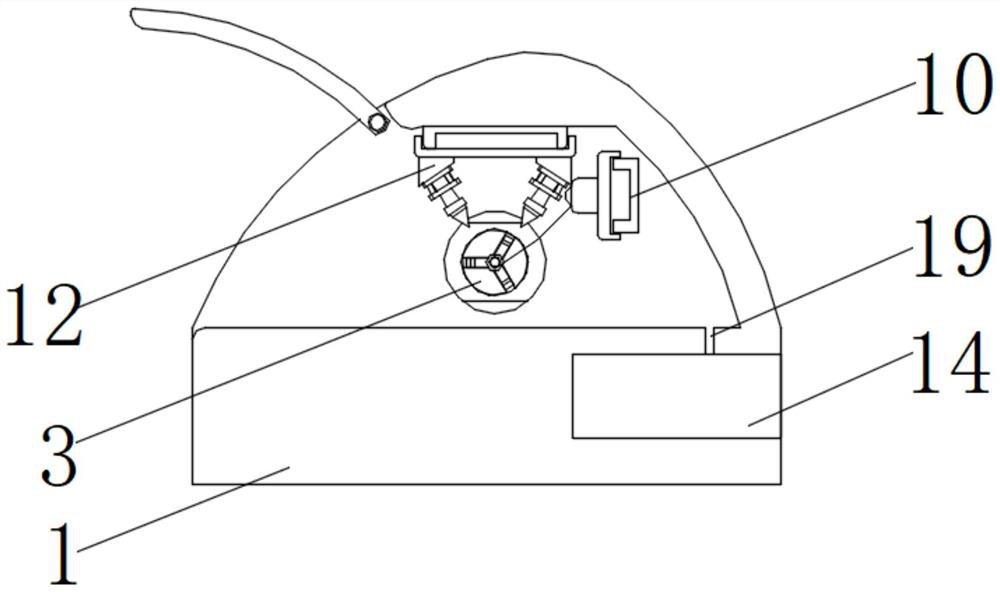

[0036] Combine below Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a cutting device for the production of stapler suture titanium nails, including a casing 1, the inner wall of the casing 1 is embedded with a fixing base 2, and the side of the fixing base 2 away from the inner wall of the casing 1 is bolted with a three-jaw clamp Disc 3, the three-jaw chuck 3 is embedded with a winding rod 6, and the winding rod 6 is detachably connected to the three-jaw chuck 3, and a cutting structure 12 is provided directly above the winding rod 6, and the cutting structure 12 is connected with the three-jaw chuck 3. The top surface of the inner wall of the casing 1 is bolted.

[0037] Specifically, the cutting structure 12 includes a second slideway 1201 bolted to the top surface of the inner wall of the casing 1 . The surface of the second slideway 1201 is embedded with a second linear motor 1202 , and the second linear motor 1202 slides with the second ...

specific Embodiment 2

[0045] refer to Figure 8 , the inner bottom surface of the casing 1 is provided with a selection slot 20, and the selection slot 20 is a blind slot. The end of the selection slot 20 is provided with a storage slot 19, and the storage slot 19 runs through the bottom surface of the casing 1, and a push rod is fixed inside the selection slot 20. 18 , and the push rod 18 is parallel to the longitudinal direction of the selection slot 20 , a defective product storage box 14 is provided directly below the storage slot 19 , and the defective product storage box 14 is slidably connected to the casing 1 .

[0046] Specifically, a central control module 15, a shape recognition module 16 and a control module 17 are arranged in the casing 1 in sequence; after the device is started, the signal is connected to the central control module 15; the shape recognition module 16 recognizes the shape of the cut titanium nail, Compare with the standard titanium nail shape in the external database, ...

specific Embodiment 2

[0047] against Figure 8 Specific embodiment 2 working principle:

[0048] In this embodiment, after the winding rod 6 and the winding roller 1004 are installed, cover the outer cover 13, start the device, and connect the signal to the central control module 15; Compare with the standard titanium nail shape in the external database, within the preset threshold range, identify the unqualified titanium nail, and send the selection slot 20 into which the unqualified titanium nail falls to the central control module 15 through a signal; The module 15 undergoes signal processing, and then sends the signal to the control module 17. The control module 17 controls the corresponding push rod 18 to push the unqualified titanium nails in the corresponding selection slot 20 into the storage slot 19, and finally fall into the defective product storage box 14. be accommodated within. The titanium nails falling on the inner bottom surface of the casing 1 are all qualified titanium nails, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com