A kind of sinker automatic maintenance cleaning equipment and maintenance method for flat knitting machine

A technology for flat knitting knitting machines and cleaning equipment, which is applied in the directions of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of misjudged unqualified sinkers and oil dirt affecting normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

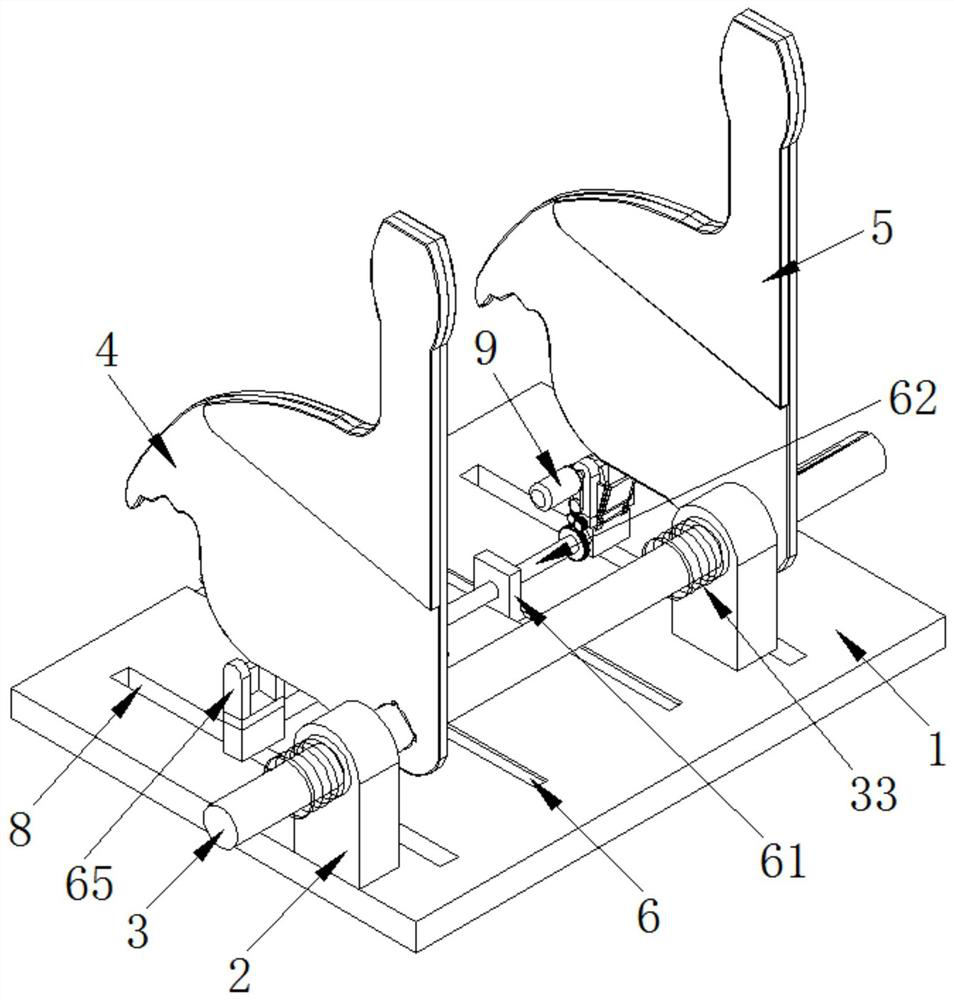

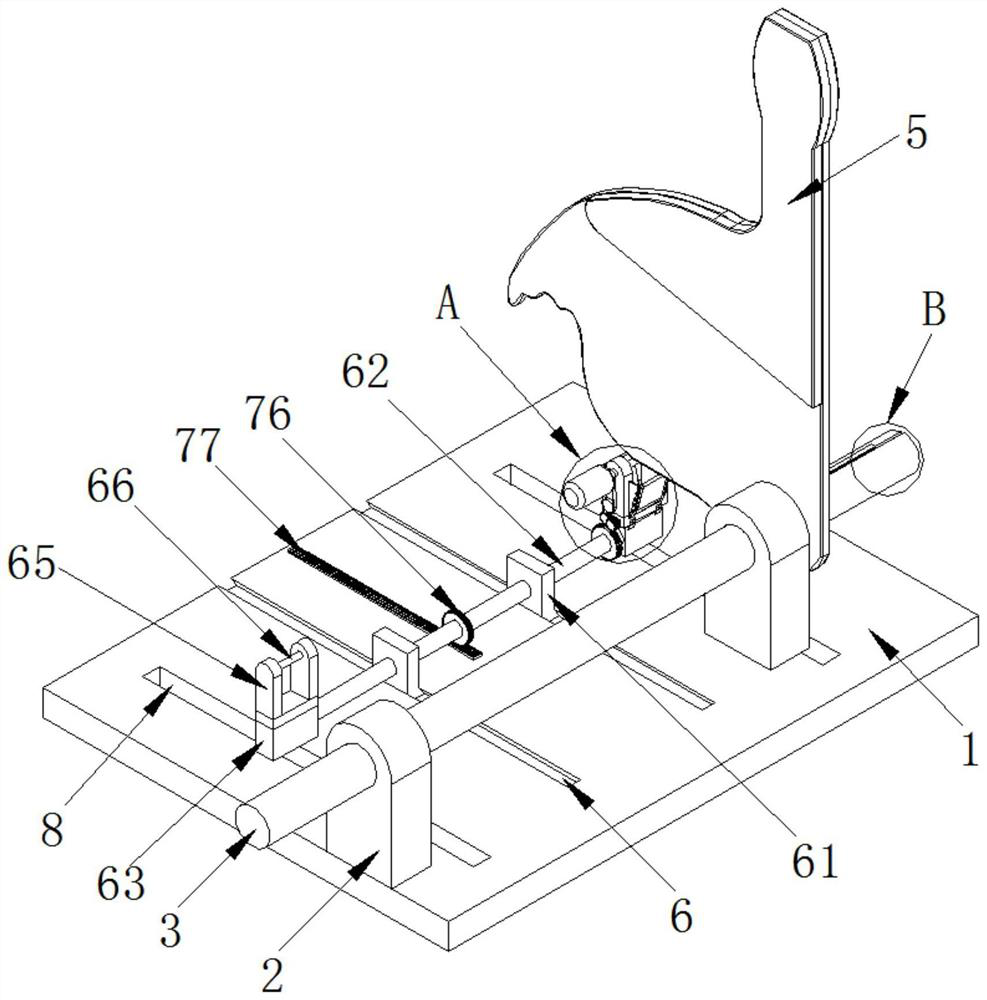

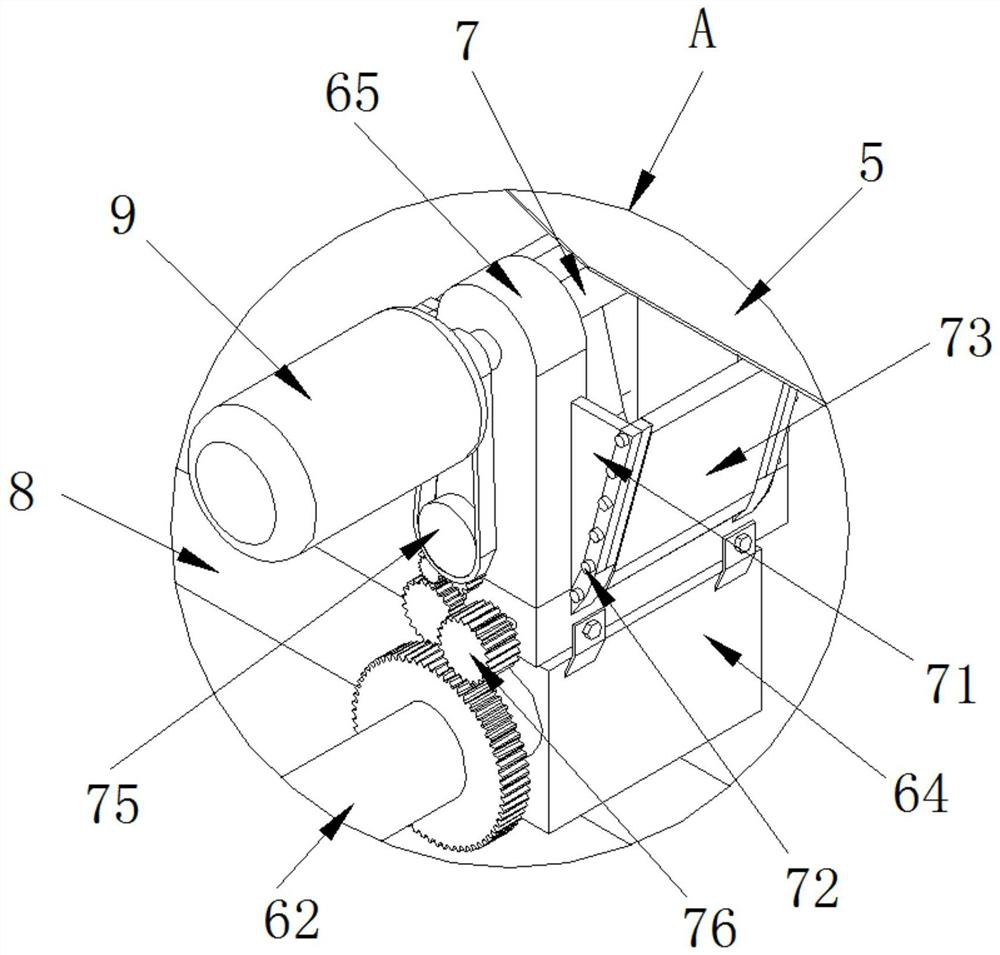

[0045] refer to Figure 1-5 , an automatic maintenance cleaning equipment and maintenance method for sinkers for flat knitting knitting machines, comprising a support plate 1 for supporting, a bearing seat 2 is fixedly installed on the upper surface of the support plate 1, and the inner ring of the bearing seat 2 is fixed A synchronous shaft 3 for socketing the sinker is installed, one end surface of the synchronous shaft 3 is fixedly socketed with a sinker template 4, and the other end surface of the synchronous shaft 3 is movably socketed with a maintenance sinker 5;

[0046] Further, the other end of the synchronization shaft 3 is movably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com