Solid waste treatment device

A solid waste and treatment device technology, applied in the field of solid waste treatment devices, can solve the problems of increased processing costs, damage to crushing devices, and messy waste, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

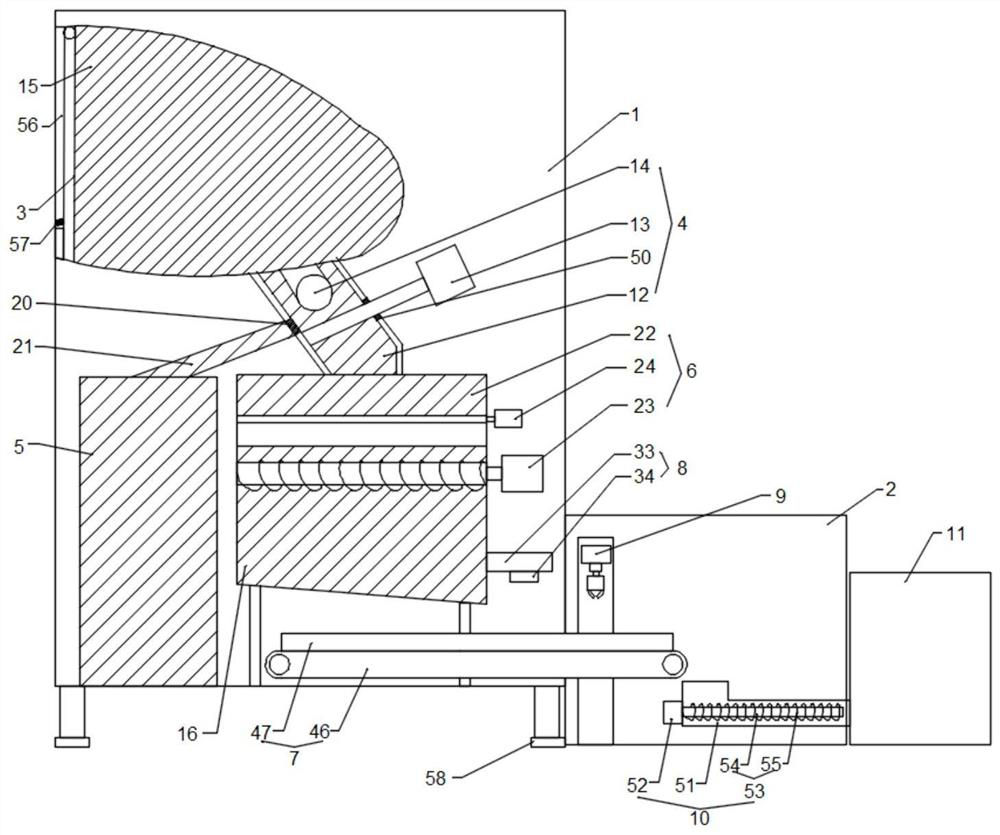

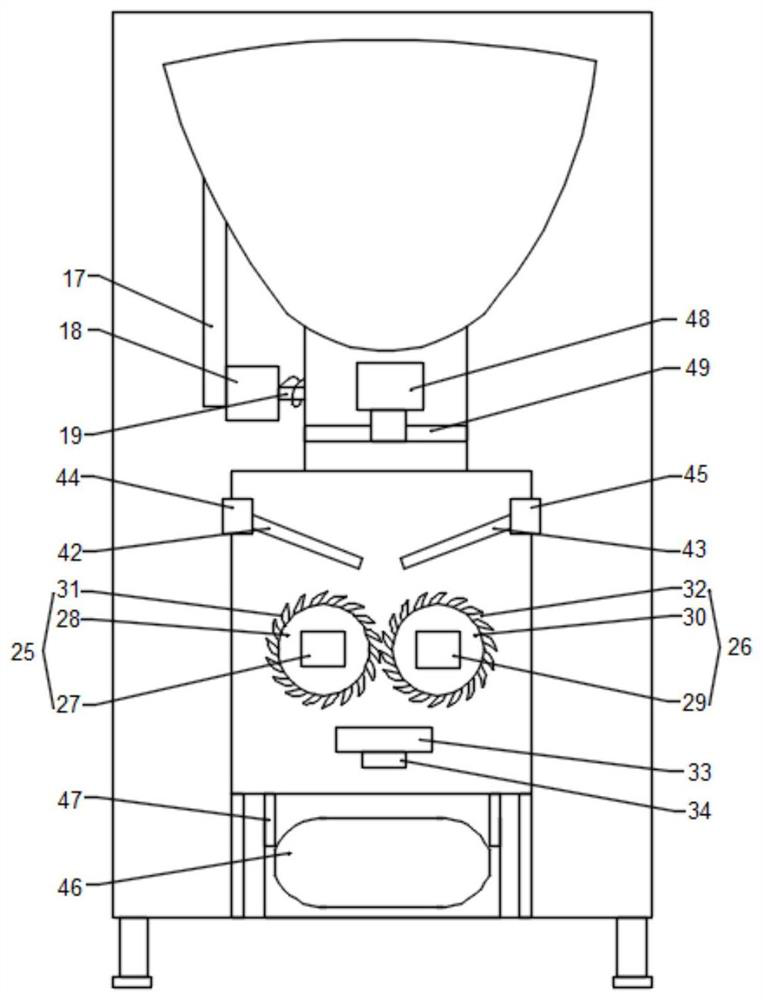

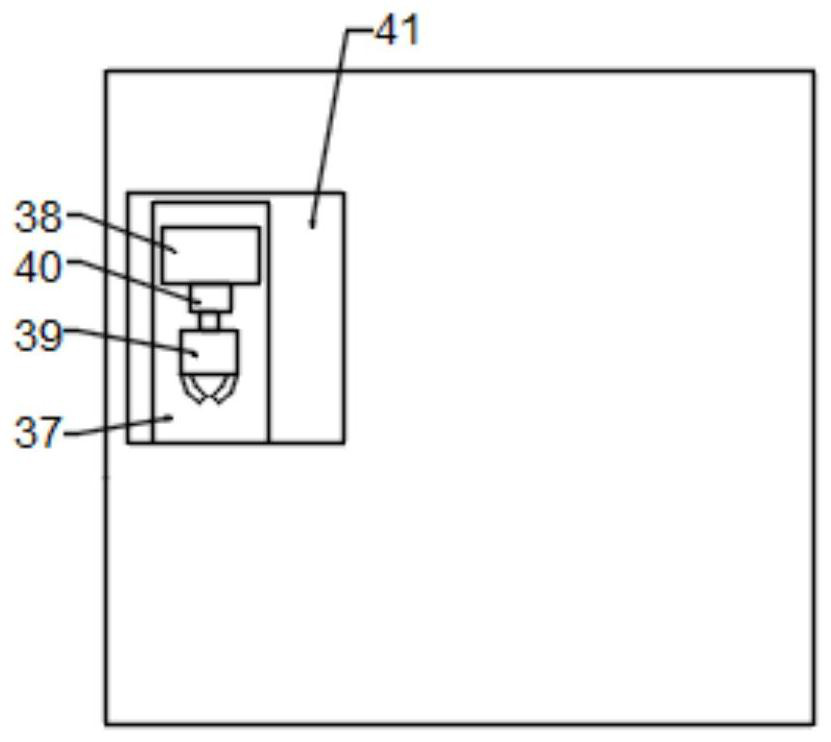

[0025] Such as Figure 1 to 4 As shown, a solid waste treatment device includes a casing 1, an extension box 2, a concentration portion 3, a dispersion portion 4, a particle collection box 5, a pulverizing portion 6, a first transfer unit 7, a detecting portion 8, a clamping portion. 9, the second transfer unit 10 and the incinerator 11, the extension case 2 is disposed on one side of the casing 1, extension the box 2 and the casing 1 to penetrate each other, concentrate 3, dispersion portion 4, particle collection box 5, pulverizing portion 6 The first transfer unit 7 and the detecting unit 8 are each disposed in the casing 1, and each of the holding unit 9 and the second transfer unit 10 are disposed within the extension box 2, the incinerator 11 is disposed on one side of the extension box 2, the second Extended to the extension box 2, the second transfer unit 10 is penetrating with the incinerator 11;

[0026] The dispersion portion 4 includes a dispersion tube 12, a switching ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap