Continuous fiber reinforced composite 3D printing head with self-cleaning function

A reinforced composite material and continuous fiber technology, applied in the field of 3D printing, can solve problems such as nozzles being easily blocked, and achieve the effects of convenient cleaning, reduced energy consumption, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

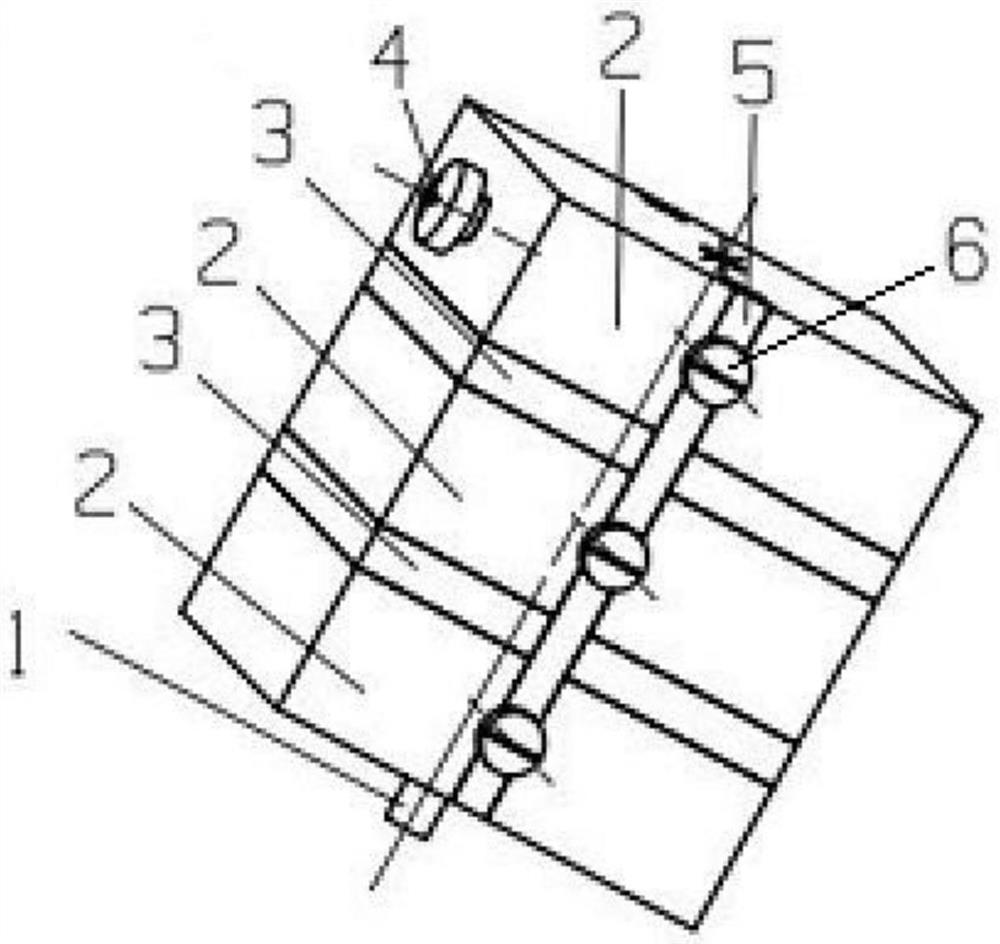

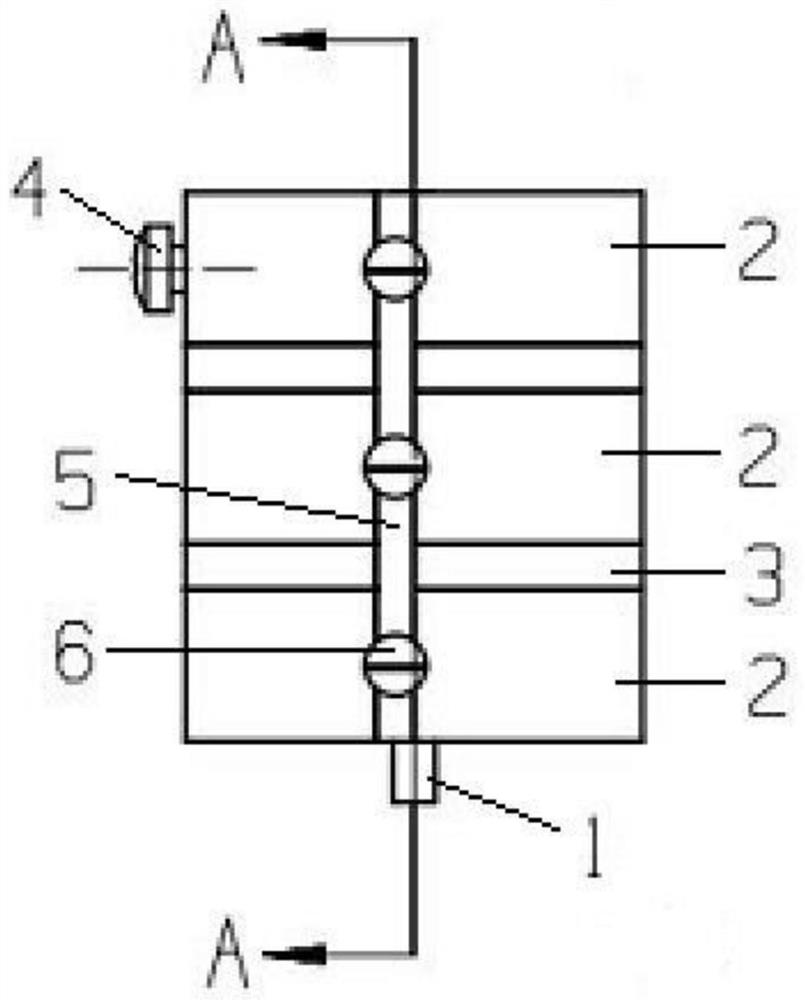

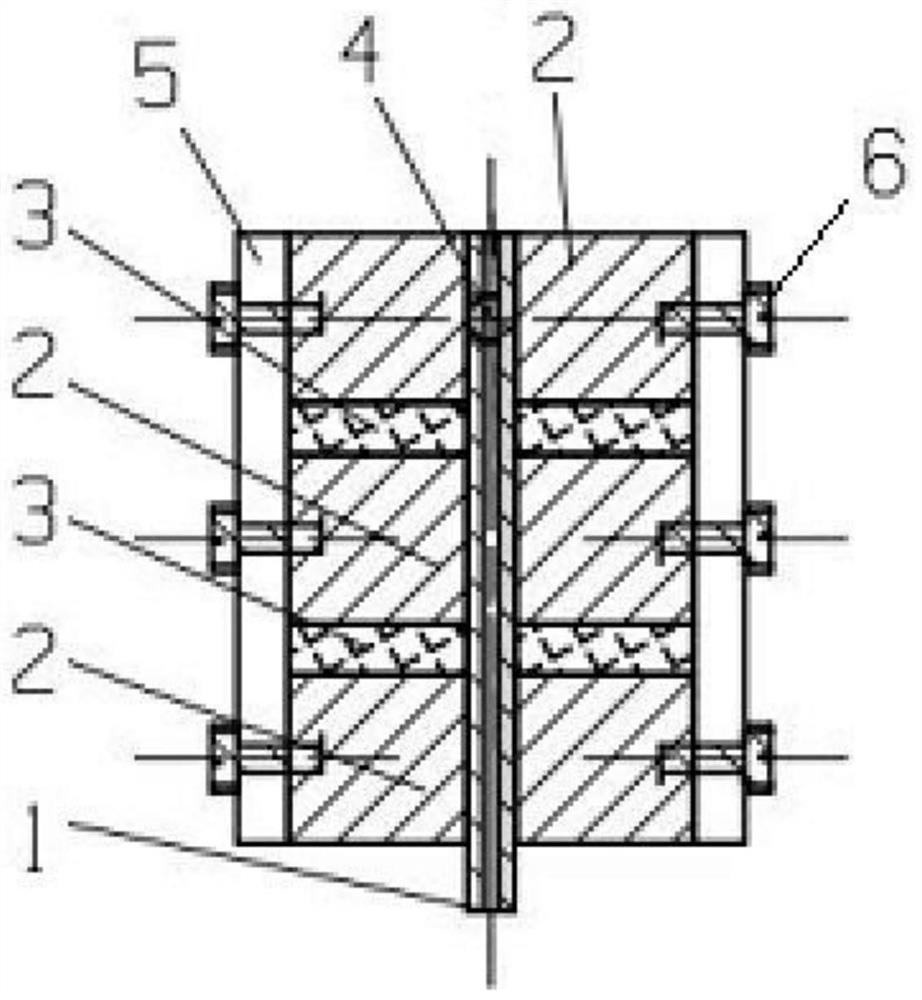

[0033] This embodiment provides a 3D printing head with no dead angle and self-cleaning function, which can prevent nozzles from being blocked during actual use, thereby facilitating continuous printing. Such as Figure 1-3 As shown, it includes a heating component, a fixed component and a metal capillary 1, and the specific structure, position and connection relationship of each component are as follows:

[0034] The heating assembly includes at least two stacked heating blocks 2. The heating block 2 can be an aluminum block or a stainless steel block. The heating block 2 is an existing conventional product, and its structural shape can be consistent with the existing conventional product. Each heating block 2 can satisfy the function of accurately controlling temperature. For example, the heating block 2 can be a square structure, and a temperature sensor and a heating rod can be arranged inside it to meet the functions of heating and temperature control.

[0035]Further, ...

Embodiment 2

[0041] On the basis of Example 1, in order to better heat the prepreg wire and ensure the plasticization quality of the prepreg wire, this embodiment adopts separate temperature control for each heating block 2. In actual operation, it is preferable to heat The heating temperature of block 2 decreases sequentially from top to bottom.

Embodiment 3

[0043] On the basis of Embodiment 1 or Embodiment 2, in order to better fix the heating component, this embodiment defines the structure of the fixing component, such as Figure 1-3 As shown, the fixing assembly includes a connecting plate 5 and a plurality of screws 6 , and the connecting plate 5 is fixed on the heating assembly through the screws 6 . Specifically, the two ends of the connecting plate 5 are respectively located on the sides of the uppermost and lowermost heating blocks 2, and each heating block 2 is provided with screw holes, and the connecting plate 5 is provided with corresponding screw holes, through which a plurality of screws 6 are respectively inserted. The connecting plate 5 can be fixed on the heating assembly through the screw holes. In order to ensure the overall stability of the heating assembly, preferably the fixing assembly is symmetrically fixed on both sides of the heating assembly.

[0044] The present invention will be specifically describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com