Visual inspection equipment for mobile phone camera bracket

A mobile phone camera and visual inspection technology, applied in the direction of television, image communication, telephone structure, etc., can solve the problems of affecting the quality of inspection, assembly, effect of mobile phone assembly, false detection of parts, etc., to achieve speed and accuracy, guarantee Safety and stability, the effect of ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

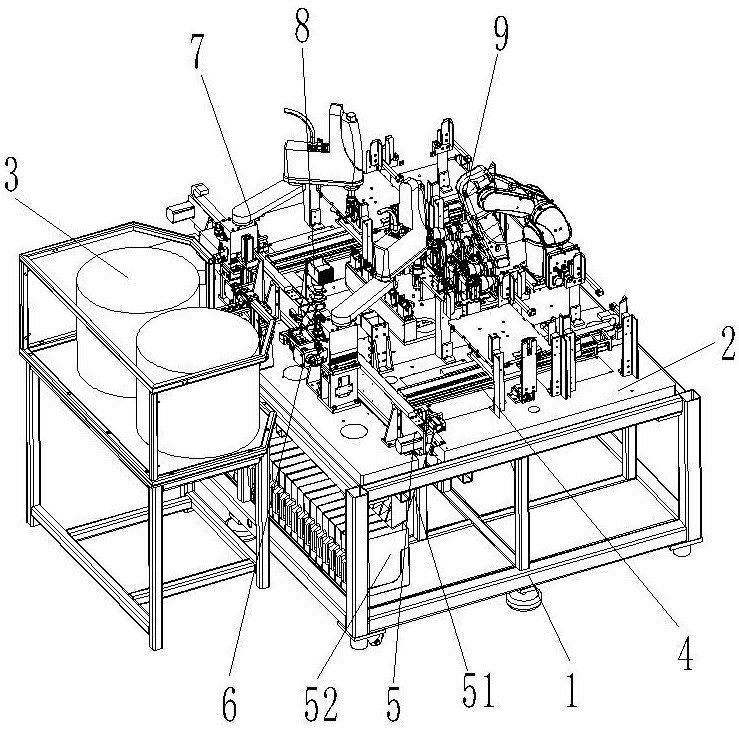

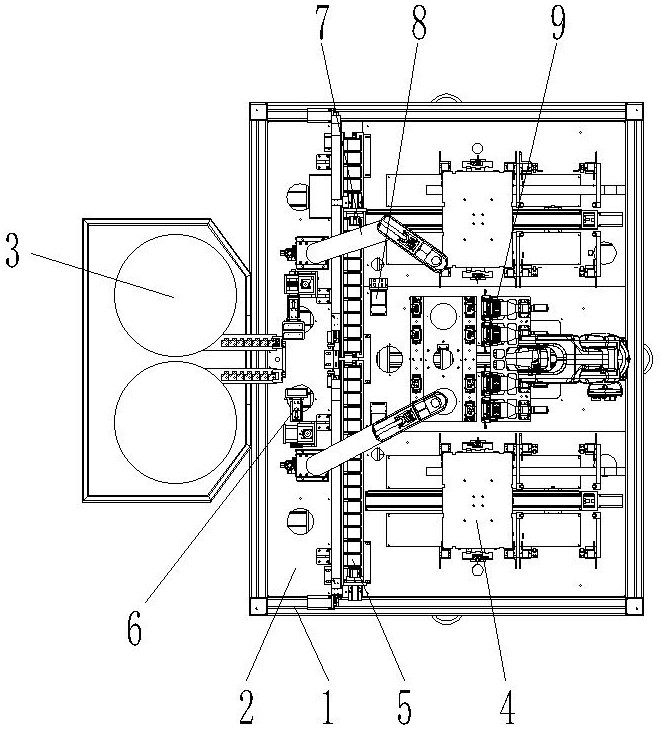

[0034] See Figure 1 to Figure 10 , the patent of the present invention has a frame 1 and a working platform 2 fixed on the frame 1; the frame 1 is provided with a vibrating plate 3 for feeding materials, and the working platform 2 is provided with a detection station and a handling station , and the blanking station, the detection station is provided with a detection mechanism for detecting the mobile phone camera bracket, and the handling station is provided with a transportation mechanism 7 for transferring the support on the vibrating plate 3 to the detection mechanism. There is a blanking mechanism 4 for screening and blanking the bracket after the detection is completed, and the transport mechanism 7 transports the workpiece to the blanking mechanism 4 after the detection is completed for screening and blanking;

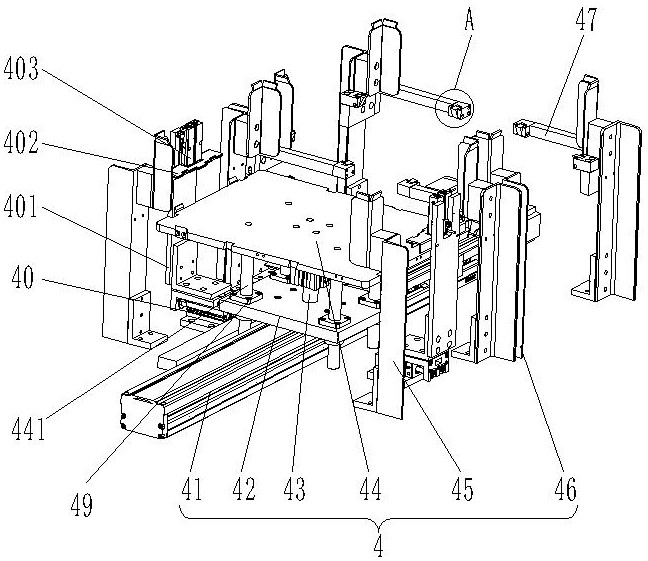

[0035] The blanking mechanism 4 includes a linear module 41 fixed on the working platform 2, a moving plate 42 which is slidably arranged on the linear module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com