A kind of release paper gluing equipment and gluing method for tape production

A technology of release paper and adhesive tape, applied in the direction of cleaning method using gas flow, cleaning method and utensils, chemical instruments and methods, etc., which can solve the problem that it is difficult to find the tape head of the tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

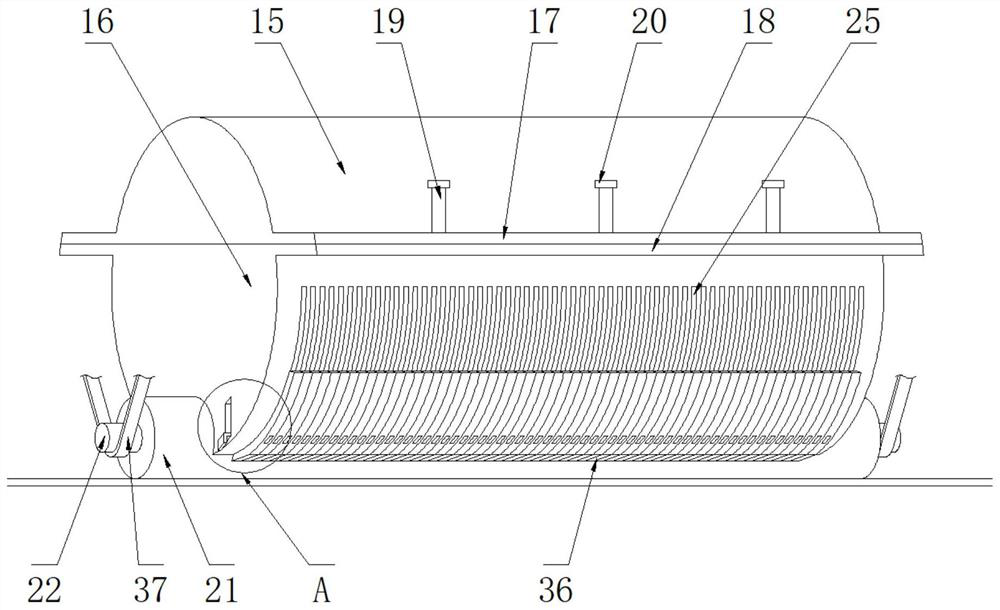

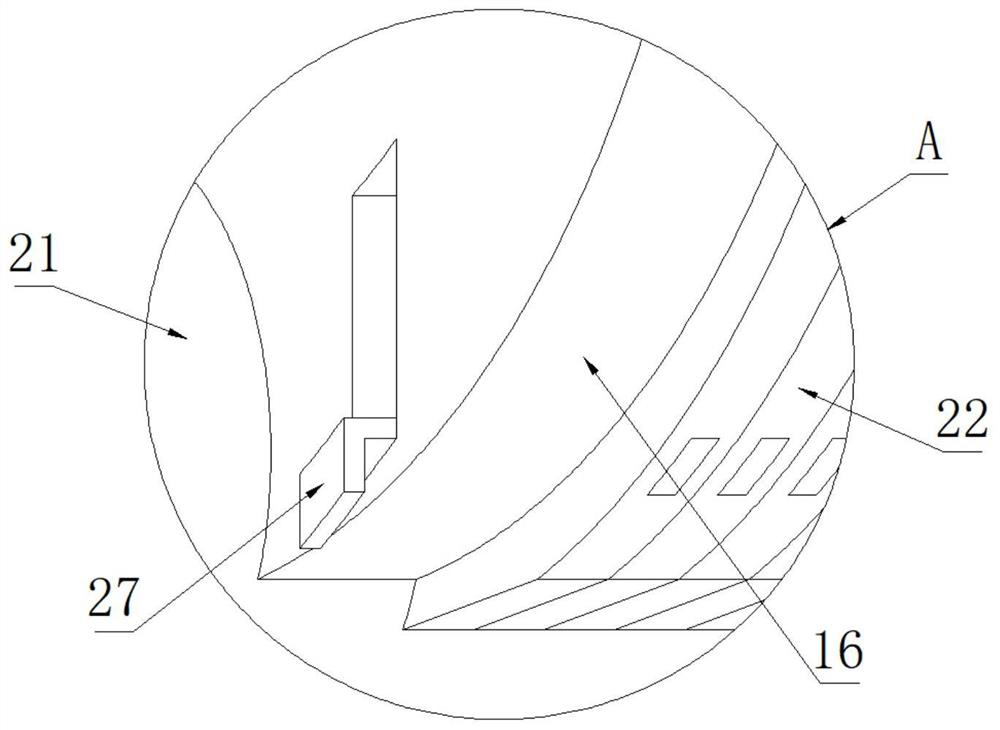

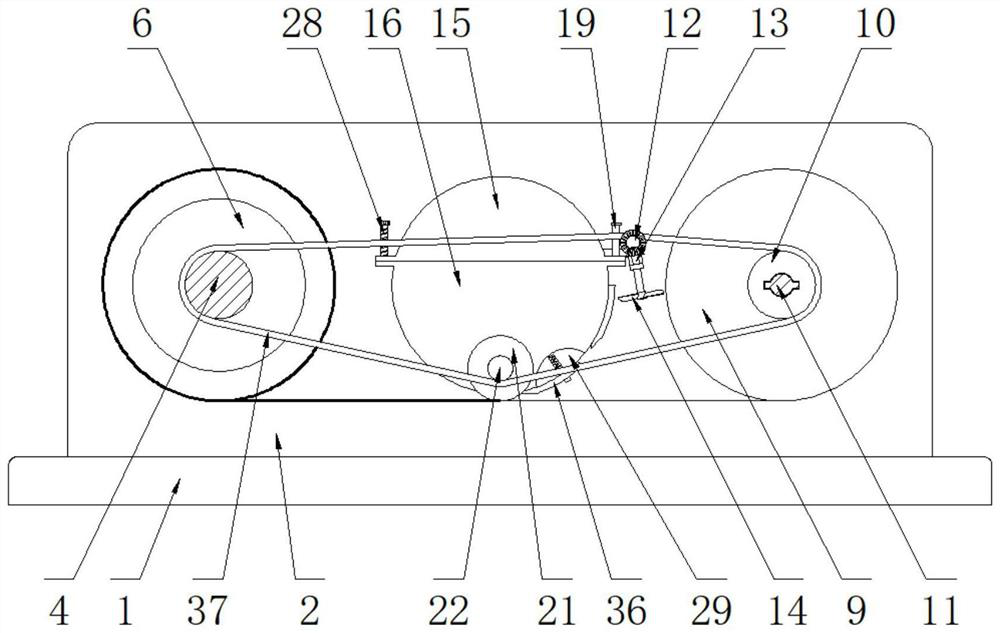

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0037] The production of adhesive tape requires the use of a glue coating device, mainly to put an adhesive layer on the surface of the release paper to ensure the stickiness of the tape. Some existing glue coating devices still have some shortcomings when they are used. In the process of gluing, it is not convenient to stably support paper tubes of different sizes. When some adjustable support devices support paper tubes, it is necessary to adjust each telescopic component several times to perform stable support work.

[0038] Moreover, some existing gluing devices usually apply gluing to the front of the tape during use, and cannot apply gluing to the local position of the tape. It is usually difficult to find the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com