Computer cooling fan capable of adjusting air volume for intelligent manufacturing

A technology for intelligent manufacturing and cooling fans, which is applied in computing, components of pumping devices for elastic fluids, and pump control. It can solve problems such as poor air volume generation and affecting the normal operation of fans.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

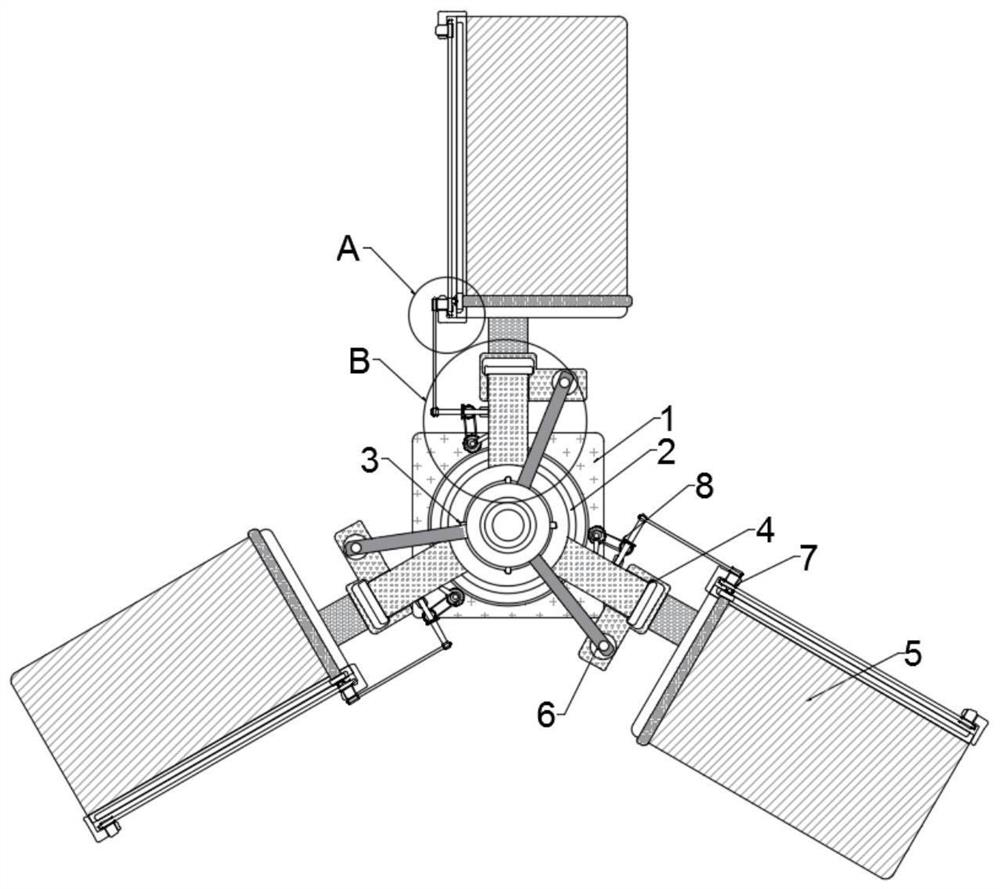

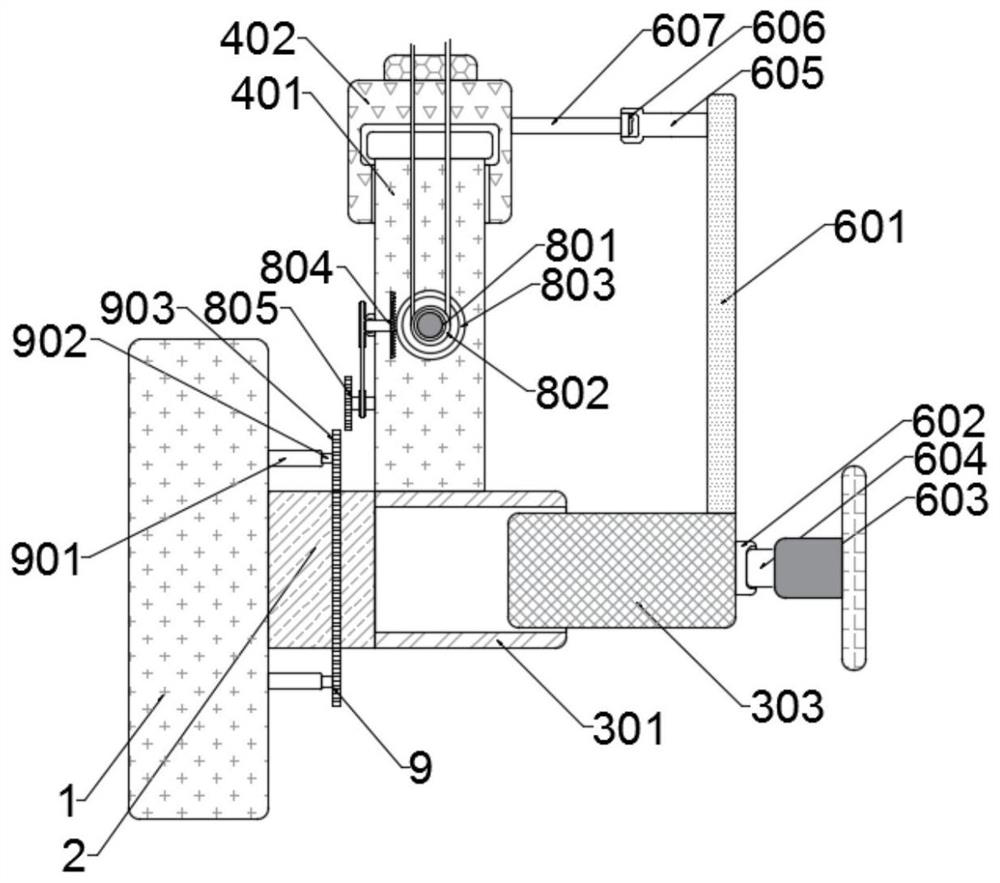

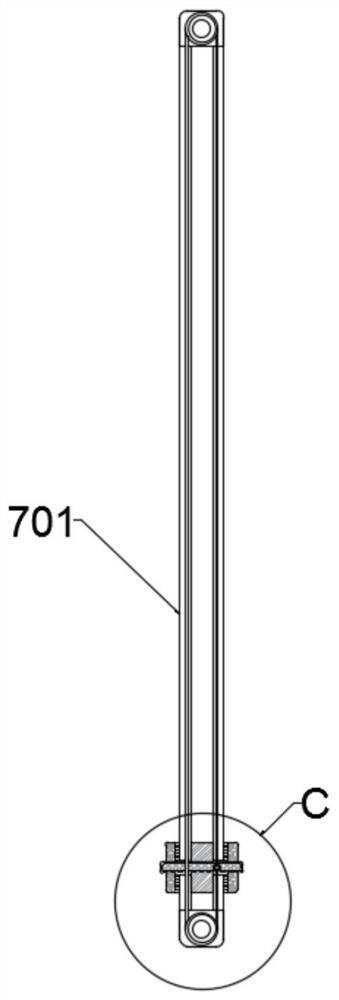

[0027] Example 1: Please refer to Figure 1-6 , a computer cooling fan capable of adjusting air volume for intelligent manufacturing, including a drive motor 1, a socket mechanism 3 is installed on the drive shaft 2 of the drive motor 1, and a connecting mechanism 4 is evenly distributed on the socket mechanism 3, and the connecting mechanism 4 A fan blade 5 is fixedly installed, an adjustment mechanism 6 is installed between the sleeve mechanism 3 and the connecting mechanism 4 , a cleaning mechanism 7 is installed on the top of the fan blade 5 , and the cleaning mechanism 7 is connected to a driving mechanism 9 through a transmission mechanism 8 .

[0028] The socket mechanism 3 includes a sleeve 301, which is fixedly installed on the drive shaft 2, and the limit groove 302 is evenly distributed in the sleeve 301, and the sleeve rod 303 is slidably installed in the sleeve 301, and the limit position is evenly distributed on the sleeve rod 303. The bar 304, the limit bar 304 ...

Embodiment 2

[0030] Example 2: Please refer to Figure 1-6 , a computer cooling fan capable of adjusting air volume for intelligent manufacturing, including a drive motor 1, a socket mechanism 3 is installed on the drive shaft 2 of the drive motor 1, and a connecting mechanism 4 is evenly distributed on the socket mechanism 3, and the connecting mechanism 4 A fan blade 5 is fixedly installed, an adjustment mechanism 6 is installed between the sleeve mechanism 3 and the connecting mechanism 4 , a cleaning mechanism 7 is installed on the top of the fan blade 5 , and the cleaning mechanism 7 is connected to a driving mechanism 9 through a transmission mechanism 8 .

[0031]The socket mechanism 3 includes a sleeve 301, which is fixedly installed on the drive shaft 2, and the limit groove 302 is evenly distributed in the sleeve 301, and the sleeve rod 303 is slidably installed in the sleeve 301, and the limit position is evenly distributed on the sleeve rod 303. The bar 304, the limit bar 304 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com