As-cast high-toughness automobile hub structure

A car hub, high toughness technology, applied in the direction of highly elastic wheels, wheels, rims, etc., can solve the problems of inability to install and disassemble the decorative plate, limited degree of adjustment of the spokes, and reduce the performance of the device, so as to facilitate multiple use and easy installation Effect of disassembly and improvement of usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

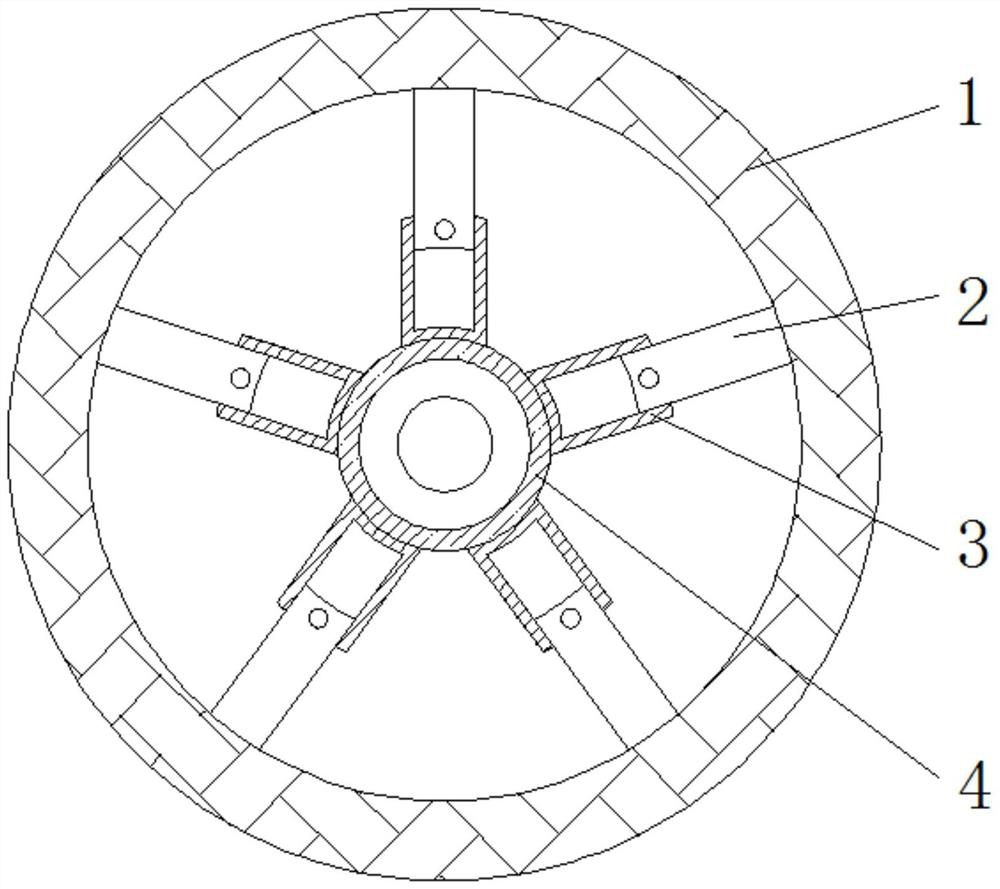

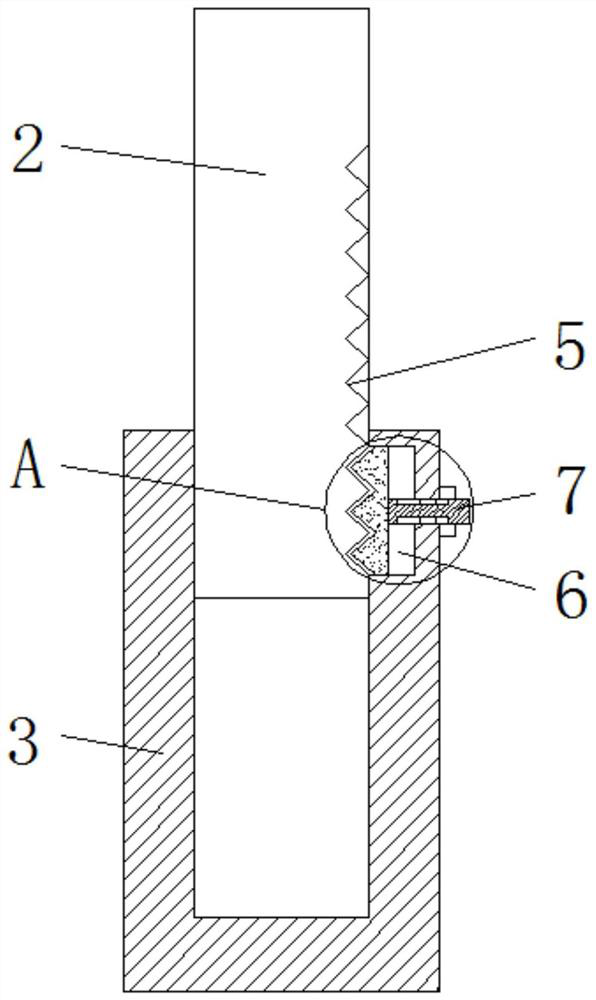

[0030] see Figure 1 to Figure 5 , the present invention provides a technical solution for a high-toughness as-cast automobile wheel structure: a high-toughness as-cast automobile wheel structure, including a rim 1, a center rim 4 is arranged at the inner center of the rim 1, and the outer surface of the center rim 4 A number of fixed spokes 3 and a number of extension spokes 2 are arranged between the rim 1, the extension spokes 2 are plugged into the interior of the fixed spokes 3, and the front end of the center rim 4 is provided with a decorative plate 12;

[0031] The extended spokes 2 correspond to the fixed spokes 3 one by one. The fixed spokes 3 are fixedly installed on the central rim 4. Several fixed spokes 3 are distributed equidistantly in a ring, and the extended spokes 2 and the rim 1 are clamped.

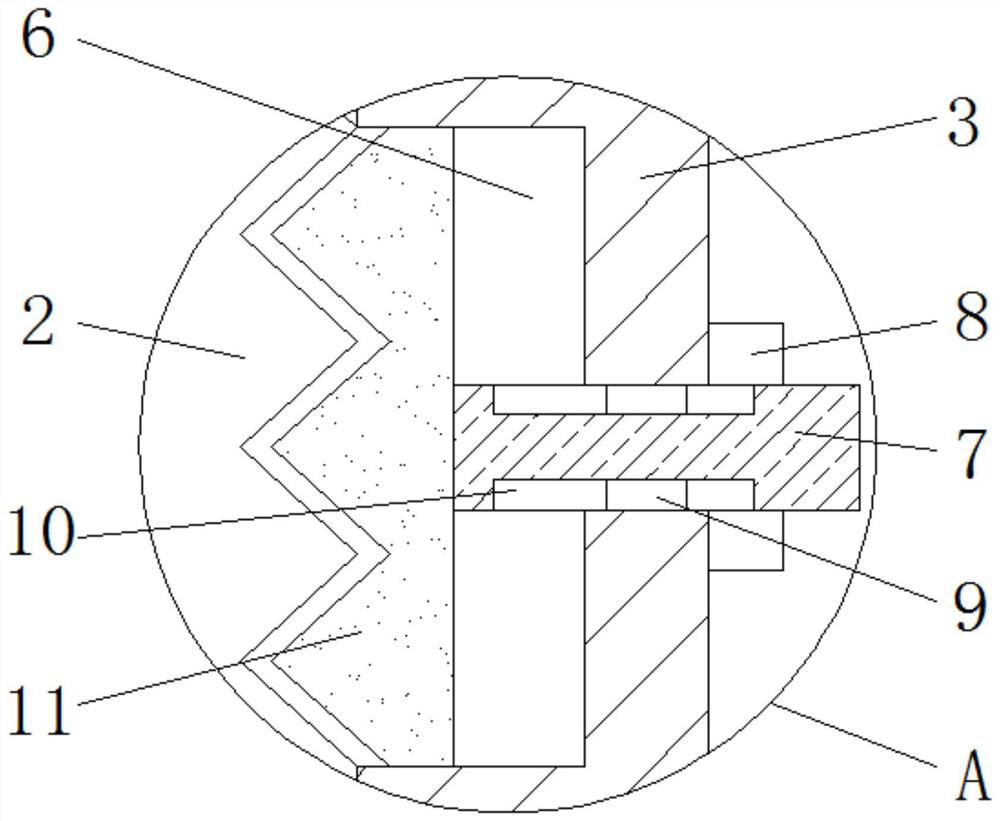

[0032] The rear end face of the inner wall of the fixed spoke 3 offers a limit groove 6, and the inside of the limit groove 6 is slidably installed with a limit plate...

Embodiment 2

[0036] Such as Figure 4 and Figure 5 As shown, under the situation that other parts are all identical with embodiment 1, the difference between this embodiment and embodiment 1 is:

[0037] A movable groove 13 is opened on the front end surface of the center rim 4 , and the decorative plate 12 is located inside the movable groove 13 and a pressure plate 14 is slidably installed inside the movable groove 13 .

[0038] The upper and lower end surfaces of the decorative plate 12 are all provided with chute 23, the position of the upper and lower ends of the inner wall of the movable groove 13 is fixedly equipped with a slide plate 22, the slide plate 22 corresponds to the chute 23 one by one, and the front end of the inner wall of the chute 23 is provided with a through groove 24, The slot 24 matches the slide plate 22 .

[0039] The central position of the front end face of the pressing plate 14 is fixedly equipped with a rotating rod 16, the first spring 15 is fixedly insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com