Transmission arm mechanism used for press feeder

A feeder and transmission arm technology, applied in the field of presses, can solve the problems of reducing production efficiency and affecting the service life of synchronous belts, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

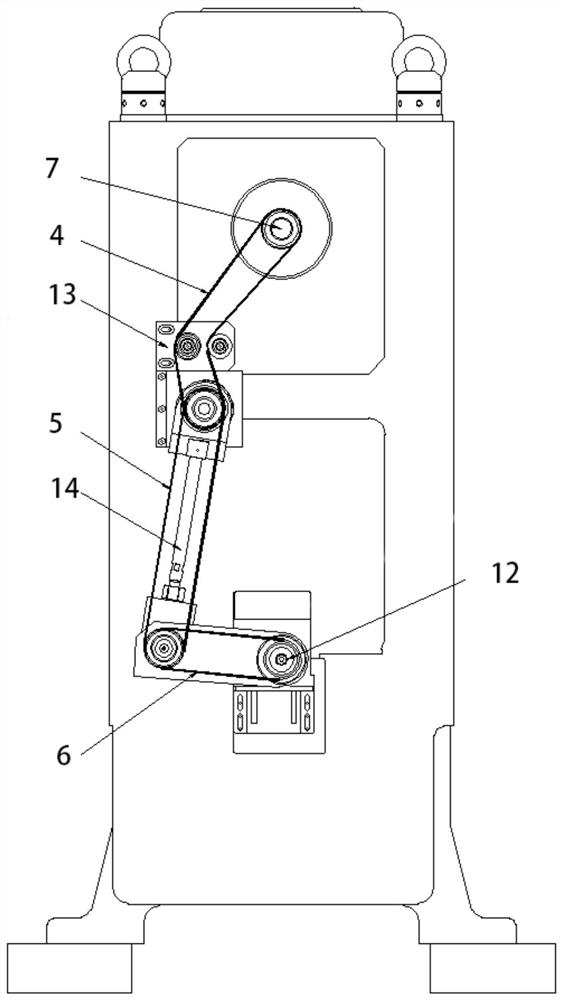

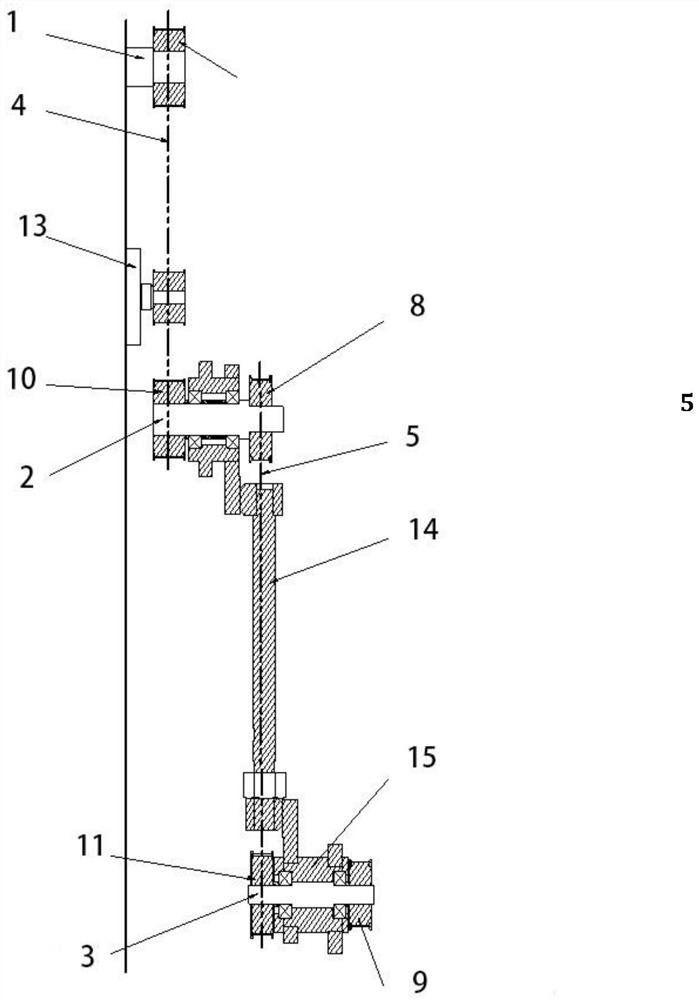

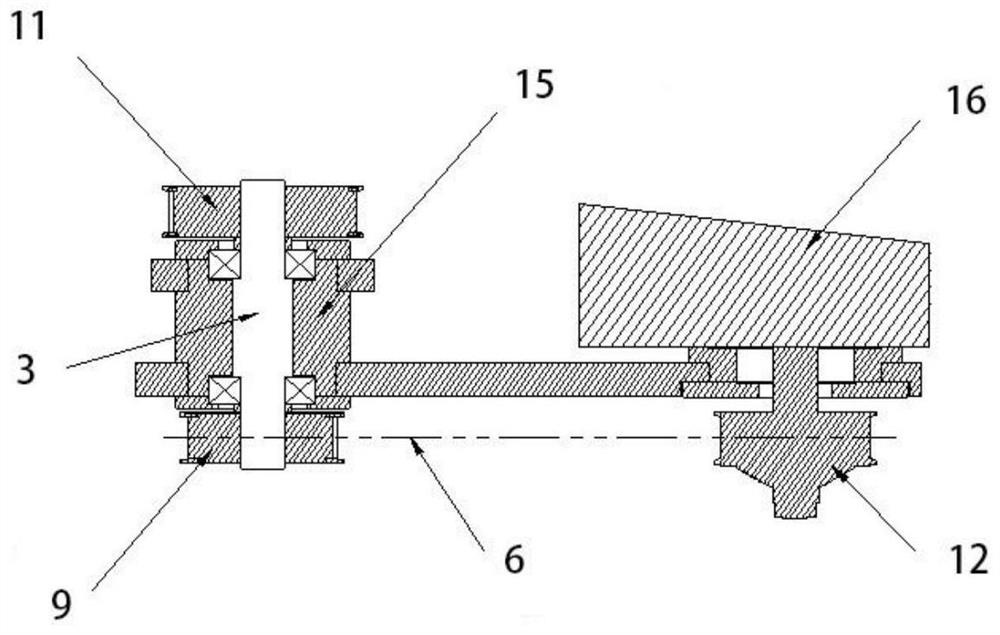

[0019] A specific embodiment of the present invention provides a transmission arm mechanism for a press feeder, please refer to Figure 1 to Figure 3 , the transmission arm mechanism for the press feeder of the present embodiment includes: a multi-stage synchronous belt transmission system, which includes a synchronous belt, a driving wheel and a driven wheel, and the driving wheel drives the driven wheel through the synchronous belt; The driven wheel is driveably connected with the driving wheel of the rear stage transmission system through a rotating shaft. The use of a synchronous belt requires frequent tensioning and loosening of the synchronous belt, which will reduce the service life of the synchronous belt. However, decomposing the synchronous belt into multiple stages and using it with a tensioning mechanism can omit the action of tensioning and relaxing the synchronous belt and prolong the synchronous belt. The service life also increases the production efficiency.

...

Embodiment 2

[0025] The difference between the second embodiment and the first embodiment is that the second synchronous belt 5 in this embodiment swings up and down with the axis of the first driven shaft 2 as the center, and the third synchronous belt 6 The axis center of moving shaft 3 is the center of circle and swings left and right. Specifically, when the second synchronous belt 5 moves upward around the axis of the first driven shaft 2 , the third synchronous belt 6 moves leftward around the axis of the second driven shaft 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com